14 replacement of parts, 11 low water pressure sensor, 13 primary heat exchanger – Glow-worm Betacom C User Manual

Page 59: 12 secondary heat exchanger

59

14 Replacement of parts

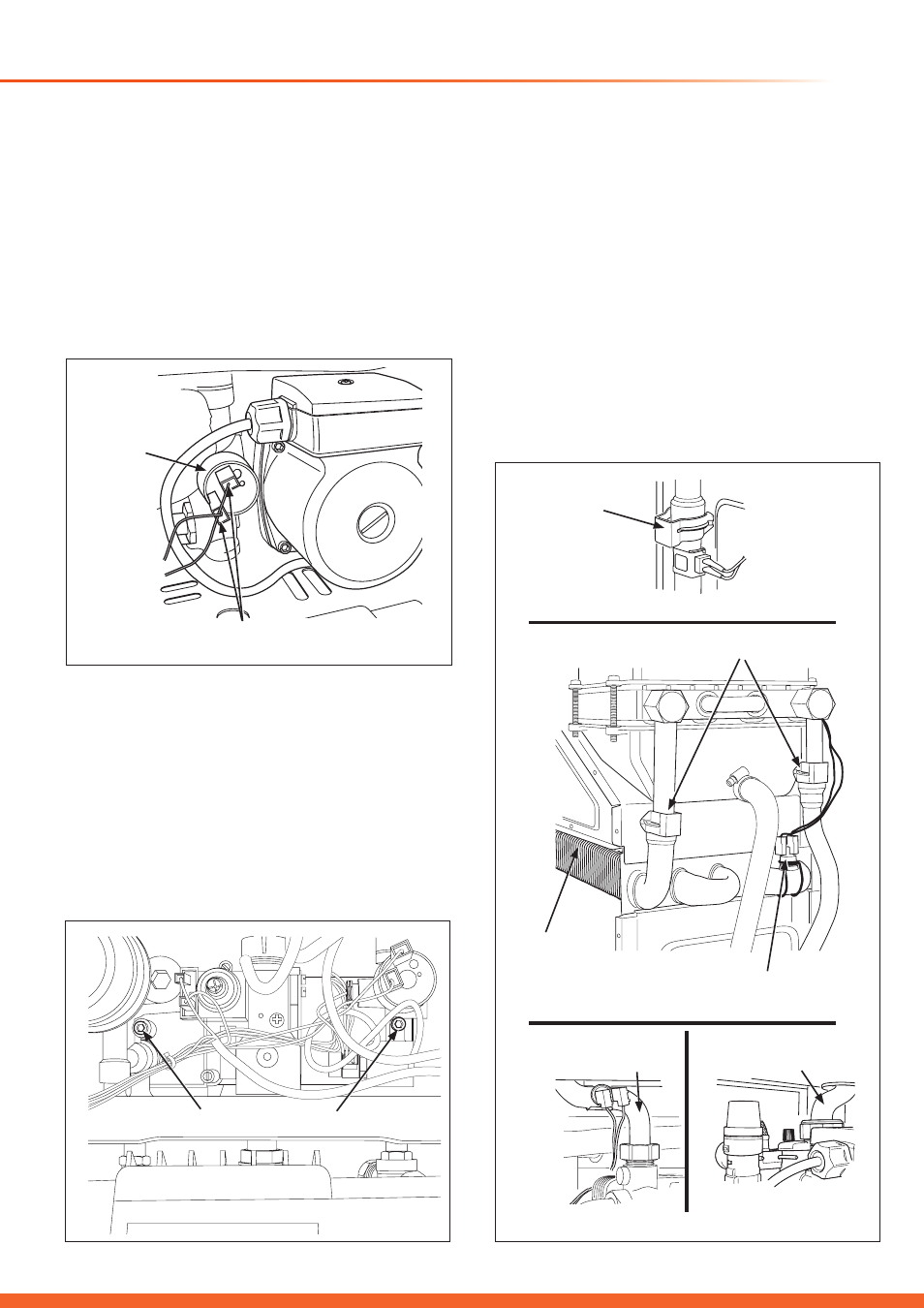

14.11 low water pressure sensor

For access, refer to section 14.1.

Drain the boiler circuit, refer to section 14.2.

Locate the low water pressure sensor at the front right

hand side of the boiler and remove the electrical sensors

connections, see diagram 14.11.

Remove the low water pressure sensor by turning it in an

anticlockwise direction.

Fit the replacement sensor in reverse order of removal

ensuring all washers are fitted.

Replace damaged washers as necessary.

Open the isolating valves on the flow and return connections,

refill, vent and re-pressurise the system ensuring all joints are

sound.

14.13 Primary Heat Exchanger

For access, refer to section 14.1.

Drain the boiler circuit, refer to section 14.2.

Refer to diagram 14.13.

Remove the pipe clips on the pipes of primary heat

exchanger.

Remove the CH temperature sensor on the return pipe.

Remove the pump and three way valve connection pipes.

Release the pipe connections, retaining the washers for

re-assembly.

Remove the combustion chamber cover, see section 12.1.

Carefully remove the heat exchanger by pulling forward taking

care not to damage the insulation.

Fit the new heat exchanger and reassemble the boiler in

reverse order ensuring all the washers are fitted, or replaced

as required.

Open the isolating valves on flow and return connections,

refill, vent and re-pressurise system ensuring the all joints are

sound.

******

14584

Diagram 14.12

Diagram 14.13

14494

Diagram 14.11

ELECTRICAL

CONNECTIONS

LOW WATER

PRESSURE

SENSOR

14.12 Secondary heat exchanger

For access, refer to section 14.1.

Drain the boiler circuit, refer to section 14.2.

Remove the two screws which connect the heat exchanger to

the L.H. / R.H. hydroblocks, see diagram 14.12.

Remove the heat exchanger from the gap on the left hand

side.

Fit the new heat exchanger checking that the plate numbers

are the same and reassemble in reverse order ensuring all

washers are fitted or replaced as required.

Open the isolating valves on the flow and return connections,

refill, vent and re-pressurise the system ensuring all joints are

sound.

OVERHEAT SAFETY

THERMOSTAT

PIPE CLIP

PIPE CLIP

PRIMARY

HEAT

EXCHANGER

THREE WAY VALVE

CONNECTION PIPE

PUMP

CONNECTION PIPE

SECURING SCREWS