13 fault finding – Glow-worm Betacom C User Manual

Page 51

51

F1

F2

br

230V

TEST

POSITION

br

br

b

b

b

b

g/y

g/y

bk

m

w

r

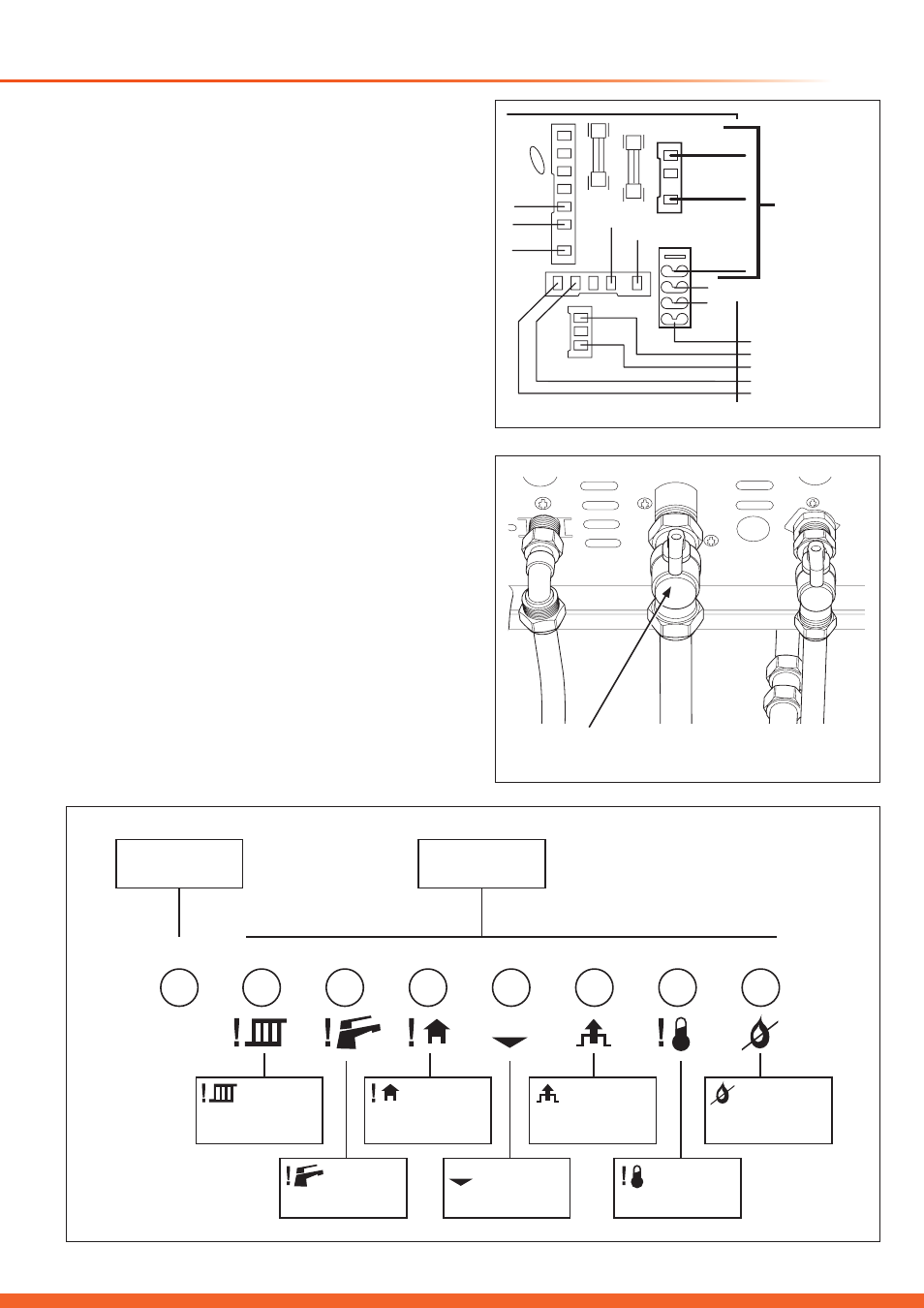

13 Fault finding

13.1 Preliminary fault finding

The following checks should be performed before proceeding

onto specific diagnostics:

Check the external electrical supply to the boiler is on and a

supply of 230V is present at the ‘L’ and ‘N’ terminals.

Check the electrical installation and boiler, carry out tests for

earth continuity, polarity, short circuit and resistance to earth,

using a suitable multimeter.

An aid to test

Remove the front casing panel, see diagram 10.1 and hinge

down the control box.

Unclip to gain access to the mains circuit board, see diagram

10.4.

Carry out the tests on the mains circuit board, see diagram

13.1.

Check chassis earth at a bare metal point on the boiler.

Check that there is a gas supply to the boiler and the gas

service isolation valve is turned on, see diagram 13.2.

Check pressure at the gas service isolation valve, refer to

section 11.5.

Check that the heating system pressure indicates at least

1.0 mbar, if not, fill and vent the system as described in

section 11.2.

Check that all external controls are on.

13.2 Re-set function

Should the boiler lock out at any time, please check the

gas supply and ionisation probe position, the boiler may be

re-started by switching to standby “O” position waiting 15-30

seconds and switching back to its previous position once the

fault has been eliminated, see diagram 11.4.

14520

Diagram 13.3

Diagram 13.2

Diagram 13.1

ON

bar

Boiler Stand-by

Indicator

Water

Temperature

Flashing

Fault on CH

sensor

Flashing

Fault on

Outdoor sensor

Flashing

Fault on Air

Pressure Switch

Flashing

Flames or Gas

Failure

Flashing

Fault on

DHW sensor

Flashing

Low System

Pressure

Flashing

Overheat

Themostat

30

40

50

60

70

80

90

bar

14571

14637

GAS SERVICE ISOLATION

VALVE (OPEN)