3 boiler location, clearances and ventilation, 1 location, 2 clearances – Glow-worm Betacom C User Manual

Page 11: 3 timber frame buildings, 4 combustible material, 5 room ventilation, 6 cupboard or compartment ventilation

11

3 Boiler Location, Clearances and Ventilation

3.1 Location

This boiler is not suitable for outdoor installation.

This boiler may be installed in any room, although particular

attention is drawn to the installation of a boiler in a room

containing a bath or shower where reference must be made to

the relevant requirements.

This boiler is suitable for installation in bathroom zones 2 and

3.

In GB this is the current I.E.E. WIRING REGULATIONS and

BUILDING REGULATIONS.

In IE reference should be made to the current edition of

I.S.813 “Domestic Gas Installations” and the current ETCI

rules.

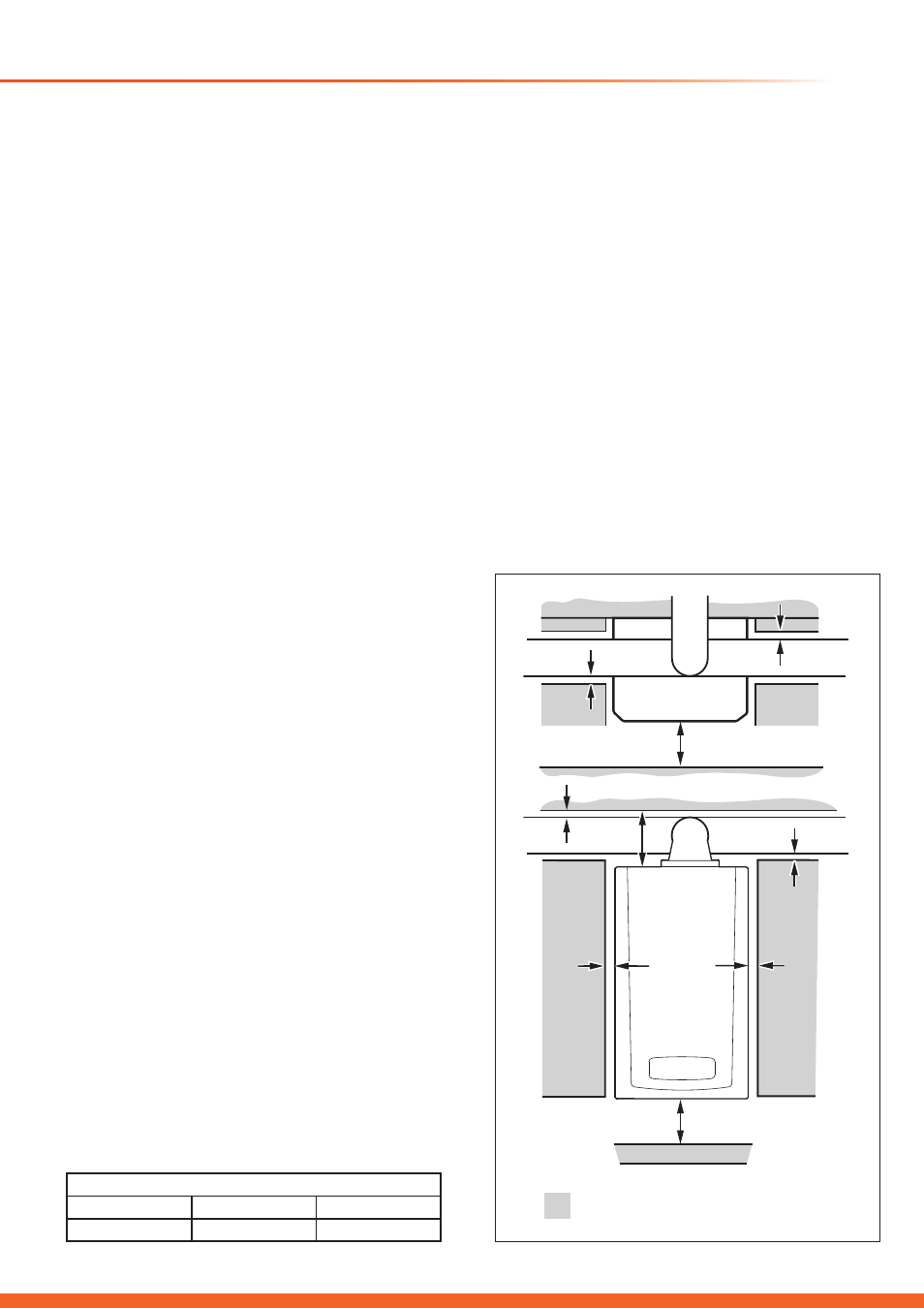

3.2 Clearances

The boiler should be positioned so that at least the minimum

operational and servicing clearances are provided, see

diagram 3.1.

Additional clearances may be beneficial around the boiler for

installation and servicing.

For flue installations where external access is not practicable,

consideration should be given for the space required to insert

the flue internally, which may necessitate clearance larger

than those specified in diagram 3.1.

3.3 Timber Frame Buildings

If the boiler is to be installed in a timber frame building it

should be fitted in accordance with the Institute of Gas

Engineers document IGE/UP/7/1998. If in doubt seek advice

from local gas undertaking or Glow-worm.

3.4 Combustible Material

The boiler and flue are suitable for installation onto and

through combustible materials provided that:-

1) The boiler must be sited at least 1m away from flammable

materials and heat sensitive walls must be protected by

appropriate insulation.

2) Minimum 5 mm clearance is maintained around the

circumference of the flue (air intake).

3) The combustible surface and fixings are suitable for

supporting the load.

4) The minimum clearances from the boiler case are

maintained.

3.5 Room Ventilation

The boiler is room sealed so a permanent air vent is not

required.

3.6 Cupboard or Compartment Ventilation

If the boiler is installed in a compartment there must be

purpose made ventilation for cooling purposes.

Make sure the cupboard or compartment air vents are

positioned to be clear of obstructions at all times.

A compartment used to enclose the boiler must be designed

and constructed specifically for this purpose.

An existing cupboard or compartment modified for the

purpose may be used. Refer to the current issue of BS6798

for guidance.

Diagram 3.1

14344

300

KEY

NON COMBUSTIBLE MATERIAL

200

20

20

20

20

600

20

20

HI LO

Betacom 24c

128.5cm²

128.5cm²

Betacom 30c

142.5cm²

142.5cm²