11 commissioning, 1 preliminaries - all systems, 2 filling the system – Glow-worm Betacom C User Manual

Page 38

38

11 Commissioning

IMPORTANT

:

At the time of commissioning, complete all

relevant sections of the Benchmark Checklist located in the

centre pages of this document.

11.1 Preliminaries - All Systems

Do Not operate the boiler without water.

The commissioning should be carried out by a

competent

person approved at the time by the Health and Safety

Executive and in accordance with the current issue of

BS6798.

Make sure that the system has been thoroughly flushed

out with cold water and that all cleanser if used has been

removed.

With the gas service isolation valve closed, with no demand

from any external controls and the power supply to the boiler

switched off, test for gas soundness and purge air from the

gas supply.

11.2 Filling the System

On completion of the boiler installation and ensuring that all

water connections are correctly made the boiler may be filled

with water via the filling loop (not supplied with the boiler).

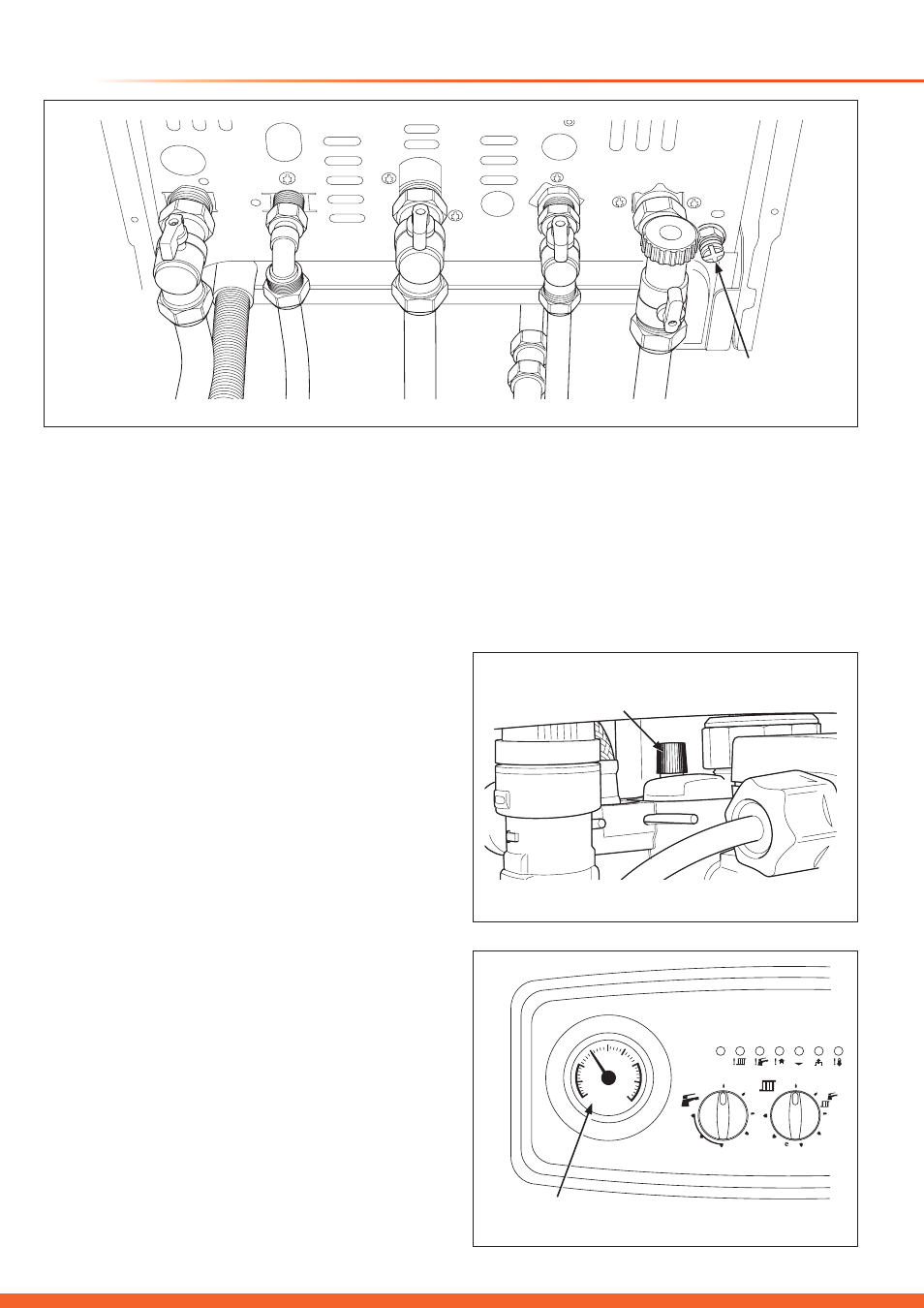

1. Ensure that two manual feed valves and boiler isolation

valves are open, see diagram 11.1.

2. Release the cover cap of the boilers automatic air vent

situated on top of the pump, see diagram 11.2.

The manual feed valves must be closed and the filling

loop disconnected once the pressure sensor, sited on the

boilers control panel, indicates a system pressure

between 1.0 and 1.5 bar, see diagram 11.3.

3. Check that all the water connections throughout the

system are sound and bleed each of the heating systems

radiators in turn. As air is vented the system pressure

may need topping back up to 1.0bar.

Air must be vented from the boiler’s pump by unscrewing

the pumps integral vent plug and allowing water to bleed

for a few seconds. Take care not to allow water to splash

onto any electrical components.

4. When the system is bled of any air it must be filled until

the pressure display indicates a system pressure of 1.5

bar.

5. If the pressure exceeds 1.5 bar discharge the excess

pressure from the system via a radiator valve or pipe

connection. Do not use the safety discharge valve

as the valve seat may become contaminated with debris

and fail to re-seal.

14571

14480

14481

Diagram 11.1

Diagram 11.2

Diagram 11.3

1

2

3

4

bar

0

ON

30

40

50

60

70

80

bar

PUMP

VENT PLUG

AUTOMATIC AIR

VENT COVER CAP

SYSTEM

PRESSURE 1.5 bar

ISOLATION VALVES SHOWN OPEN

IMPORTANT NOTE: In order to maintain the appliances

warranty; after initial filling the heating system must be

thoroughly flushed using a propriety cleanser to remove

foreign material and contaminants.