5 water system - heating, 14 5.1 general, 2 safety valve – Glow-worm Betacom C User Manual

Page 14: 3 expansion vessel, 4 flow rate, 5 water treatment, 6 general, 7 bypass, 8 filling the sealed system, 9 draining points

14

5.1 General

The boiler is designed to operate on fully pumped,

pressurised sealed systems operating at a maximum of 3bar

pressure and maximum design flow temperature of 85°C.

5.2 Safety Valve

The safety valve is an integral part of the boiler and it cannot

be adjusted.The pipe from the safety discharge valve must

not discharge above an entrance, window or any type of

public access area.

5.3 Expansion Vessel

The boiler’s integral expansion vessel with a capacity of 7

litres (1.5 gallons), is pre-charged to a pressure of 0.5bar

and will accommodate a system volume of 125 litres at an

average water temperature of 75°C and maximum system

pressure of 3 bar.

NOTE: The expansion vessel volume

depends on the total water system volume and the initial

system design pressure.

In GB, Guidance on vessel sizing is

also given in the current issue of BS5449 and BS7074 Part 1.

In IE, current edition of I.S.813 “Domestic Gas Installations”.

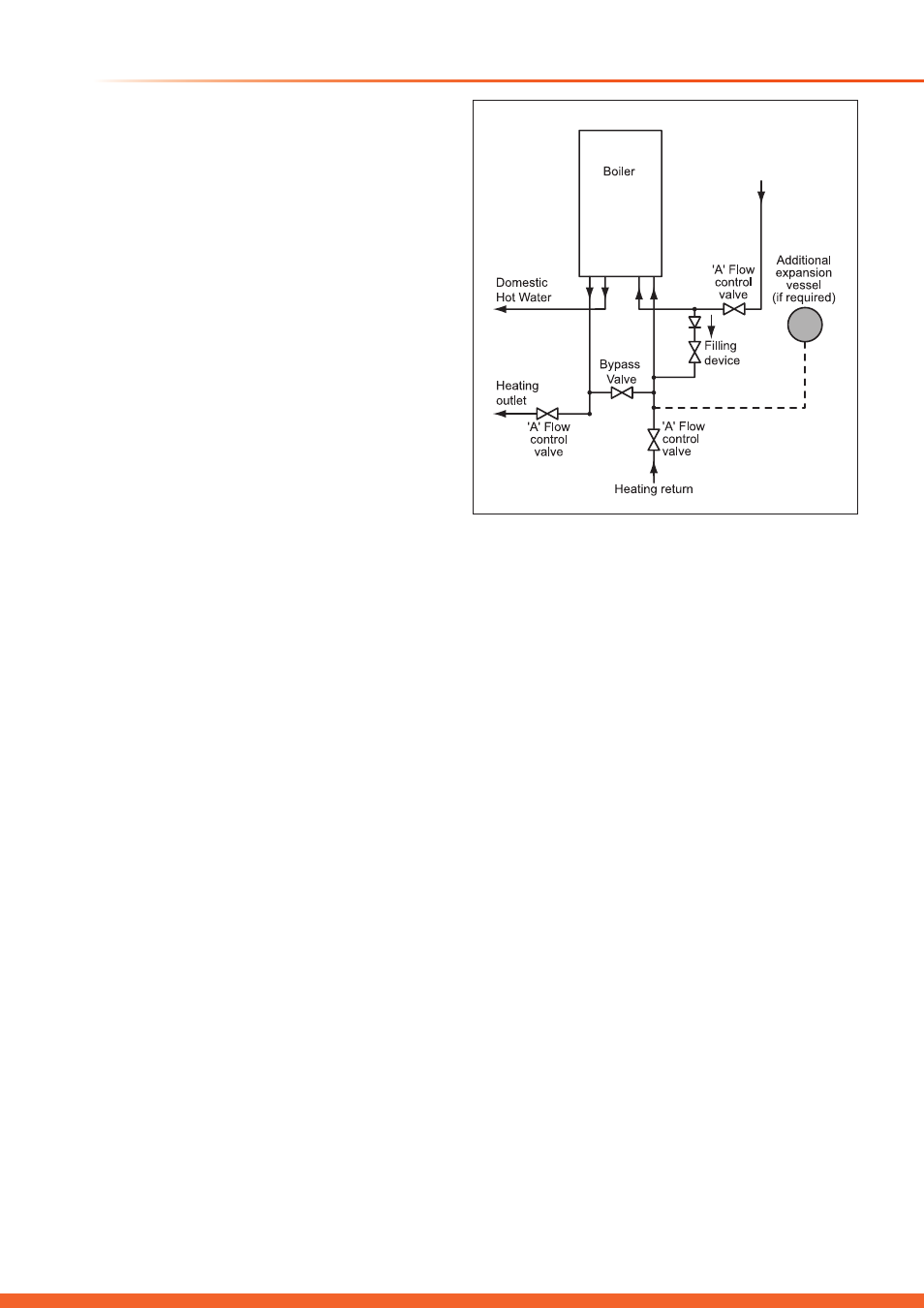

If the system volume is more than 125 litres. an additional

expansion vessel must be fitted to suit the size of the system.

A typical installation of an additional pressure vessel is shown

in diagram 5.1.

5.4 Flow Rate

If it is necessary to alter the flow rate, the system can be

fitted with a lockable balancing valve in the main flow or

return pipes shown as valve “A” in diagram 5.1. The flow rate

through the boiler must not be allowed to fall below that given

in Boiler Specification Table.

The heating circuit should be designed and balanced to give a

20°C temperature rise across the boiler flow and return.

5.5 Water Treatment

Existing system- It is ESSENTIAL that prior to installing the

new boiler the system is thoroughly flushed.

New system- For optimum performance after installation, the

boiler and its associated central heating system should also

be flushed.

Flushing should be carried out in accordance with BS7593:

2006 using a cleanser such as Sentinel X300 or X400, Fernox

Restorer or Salamander corrosion guard cleaner.

IMPORTANT: Ensure all cleanser is removed from the whole

system before adding an inhibitor.

Although the boiler is designed to inhibit the formation of

scale, in hard water areas above 200mg/l, a proprietary scale

reducer should be fitted in the cold water supply to the boiler.

Failure to comply with this requirement may invalidate your

guarantee. Refer to the current issue of BS 5449 and BS

7593 on the use of inhibitors in central heating systems.

5 Water System - Heating

5.6 General

On installation it is important to ensure that the heat

exchanger is not a natural collecting point for air and where

possible, the system pipe work should have a gradient to

ensure any excess air is carried naturally to other purpose

made, air release points.

In high water volume systems or under floor heating systems

where prolonged operation of the boiler is expected at

temperatures below 60

0

C, a by-pass must be installed on the

boiler outlet in order to prevent condensation forming inside

the boiler body. Failure to comply with this requirement will

invalidate the manufacturer’s guarantee.

5.7 Bypass

The system’s water must always be allowed to circulate

whenever the circulation pump is running. A return by-pass

must be provided.

NOTE: It is no longer permissible to use non-thermostatic

radiator valves to allow by-pass through a radiator.

Diagram 5.2 shows the pump head remaining for the heating

system depending on the bypass setting and the speed

setting of the pump, see section 12 Commissioning.

Ensure that under no circumstances does the flow rate drop

below the figure specified, refer to Boiler Specification Table.

5.8 Filling the Sealed System

With water via the filling loop, see diagram 5.3, (the filling loop

is not supplied with the boiler).

5.9 Draining Points

Draining taps must be provided at all low points of the system,

which will allow the entire system to be drained.

Draining taps shall be to the current issue of BS2879.

Diagram 5.1

14561