1 system connection, 2 safety discharge pipe, 3 boiler hanging – Glow-worm Betacom C User Manual

Page 18

18

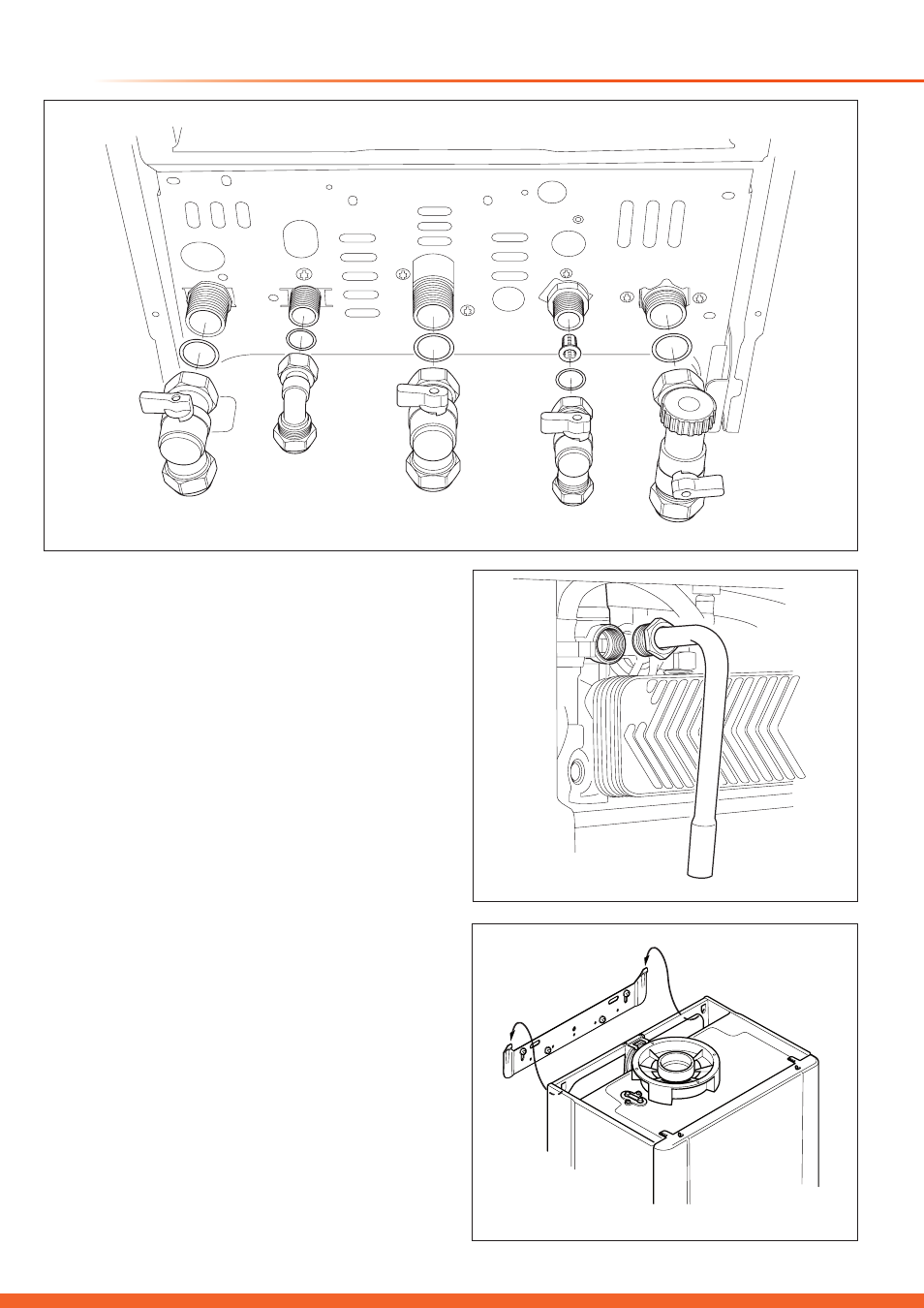

Diagram 7.2

ISOLATION VALVES SHOWN CLOSED

14348

14347

7 Boiler fixing, Gas / Water / Safety Discharge Connections

7.1 System connection

Connect the isolation valves including sealing washers and

cold water inlet filter to the boiler ensuring the washers are

fitted correctly, see diagram 7.1.

Make sure the isolation valves are closed.

7.2 Safety Discharge Pipe

Connect the safety discharge pipe, see diagram 7.2.

This must be extended, using not less than 15mm o.d. pipe,

to discharge, in a visible position, outside the building, facing

downwards, preferably over a drain.

To ease future servicing it is advisable to use a compression

type fitting to extend the safety discharge valve tube.

The pipe must have a continuous fall and be routed to a

position so that any discharge of water, possibly boiling,

or steam cannot create any danger to persons, damage to

property or external electrical components and wiring.

7.3 Boiler Hanging

Lifting the boiler into position, lean the top of the boiler slightly

to the wall and position just above the hanging bracket. Lower

the boiler slowly onto the hanging bracket making sure the

boiler is located in the boiler mounting slots, see diagram 7.3.

IMPORTANT: With regards to the Manual Handling

Operations, 1992 Regulations, the following lift operation

exceeds the recommended weight for a one man lift, refer to

section 17 Manual Handling.

Diagram 7.3

14346

Diagram 7.1

VIEWED FROM THE

REAR OF THE BOILER