14 replacement of parts, 6 air pressure switch, 8 printed circuit board – Glow-worm Betacom C User Manual

Page 57: 7 burner, 9 pump head

57

14 Replacement of parts

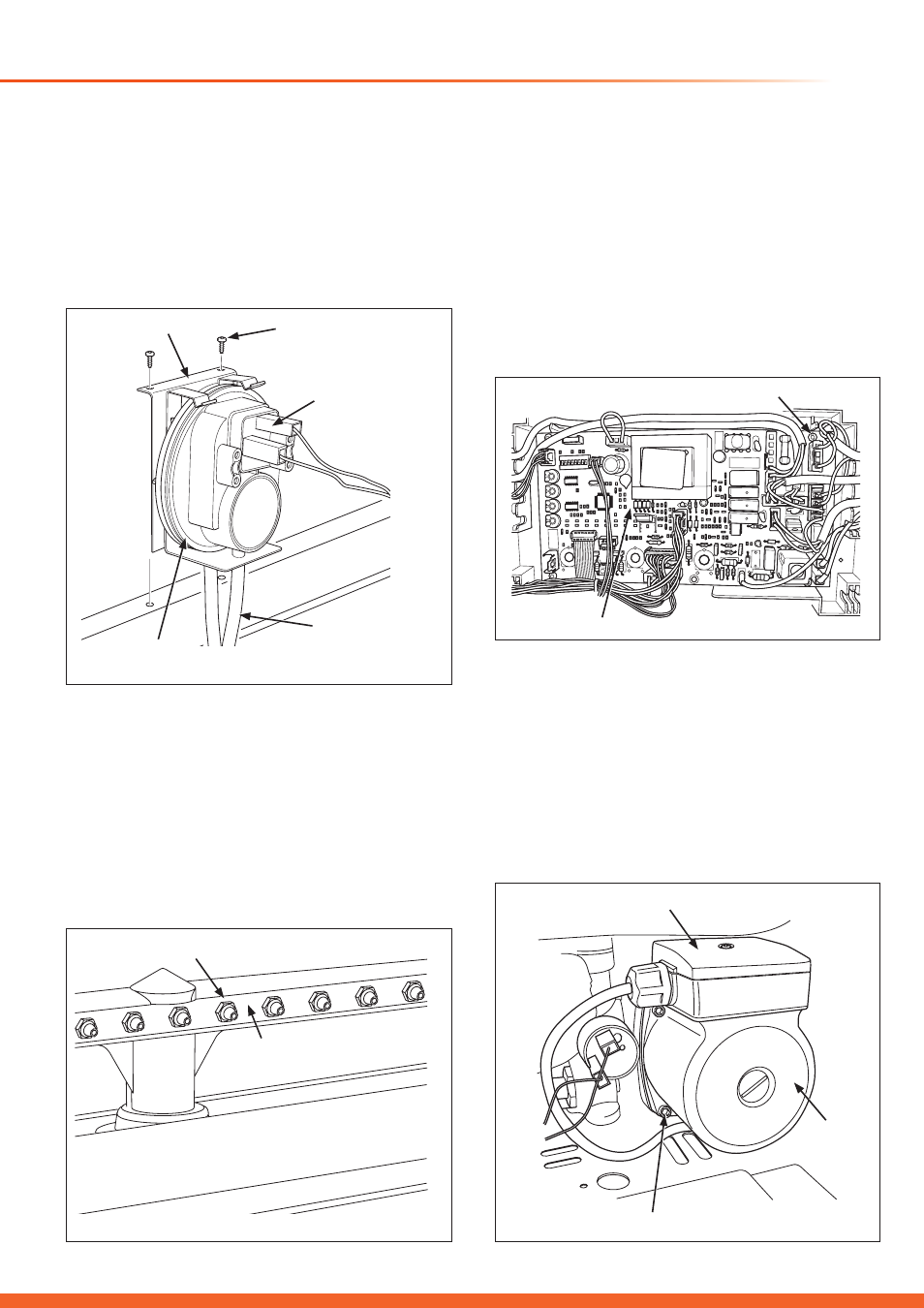

14.6 Air pressure switch

For access, refer to section 14.1.

The air pressure switch is located above the expansion

vessel, see diagram 14.3.

Remove the sensing tubes and electrical connections from

the air pressure switch, noting which tube is connected to

which port.

Remove the air pressure switch by unclipping it from the

bracket.

Fit the replacement air pressure switch in reverse order of

removal.

14.8 Printed circuit board

For access, refer to section 14.1.

Turn off and isolate the electrical supply.

Unclip the two front retaining clips on the controls fascia, see

diagram 10.3.

Unclip and carefully pull down the control circuit board cover,

see diagram 10.4.

Remove the electrical connections to the PCB by pulling

carefully, noting the locations of all the terminals.

Release the four screws securing the PCB to the control panel

and lift out the PCB.

Fit the replacement PCB in reverse order to removal, ensuring

that the PCB electrical connections are fully pushed home.

Check and re-set as necessary the potentiometers and dip

switches to the same value as the old PCB.

14543

14578

14494

14577

Diagram 14.3

Diagram 14.5

Diagram 14.6

Diagram 14.4

14.7 Burner

Refer to section 12.3. to replace the burner.

Retain all washers/gaskets for use on re-assembly.

Remove the burner injectors as shown in diagram 14.4.

Fit the burner injectors to the new burner injector bar and

tighten, ensuring that the injector size, marked on each

injector is the same as stated in the ‘Boiler Specification

section’ page 8, for the type of gas being used.

Replace the burner bar and re-fit the burner blades (replace

any damaged seals as necessary).

Fit replacement burner in reverse order.

Check gas soundness and boiler operation.

14.9 Pump head

For access, refer to section 14.1.

Drain the boiler’s circuit as detailed in section 14.2.

Remove the screws, see diagram 14.6.

Pull off the motor, remove the cover and disconnect the

electrical connections from cable box.

Fit the replacement motor in reverse order ensuring correct

polarity of the electrical connections.

Re-open the isolating valves on the flow and return

connections, refill, vent and re-pressurise the system, check

for leakage.

ELECTRICAL

CONNECTIONS

AIR PRESSURE

SWITCH

SENSING TUBES

(2 OFF)

BURNER

INJECTOR BAR

PUMP

HEAD

INJECTOR

COVER

BRACKET

SECURING

SCREWS (2 OFF)

SECURING SCREWS (4 OFF)

SECURING SCREWS (4 OFF)

PRINTED CIRCUIT BOARD