Mounting your xl 650, Initial set up – Dillon Precision XL 650 User Manual

Page 6

7

2. Mounting your XL 650:

A.

Locate a sturdy bench at least

24” wide and 14” deep, with 44” of

overhead clearance. We suggest a

minimum of 1” plywood or equivalent,

secured to the back wall. The work-

bench should be tall enough to place

your eye level about 18” above the

bench.

Note: It is important that the leading edge

of the bench has an overhang of at

least 3/4”. If the overhang is less

than 3/4”, the crank will interfere

with the front of the bench when the

operating handle is lowered. Unless

you have Strong Mounts, then none

of this is necessary.

B. Tools Needed:

You will need the following to mount and

set up your machine:

1. Electric drill

2. 17/64” drill bit preferred, 1/4” – 9/32” OK

3. Mounting Hardware Kit (#14355) or

four 1/4” through bolts with nuts and

washers

Note: The bolts should be at least 1 1/2”

longer than the thickness of the

mounting surface.

4. Two 7/16” wrenches if using kit

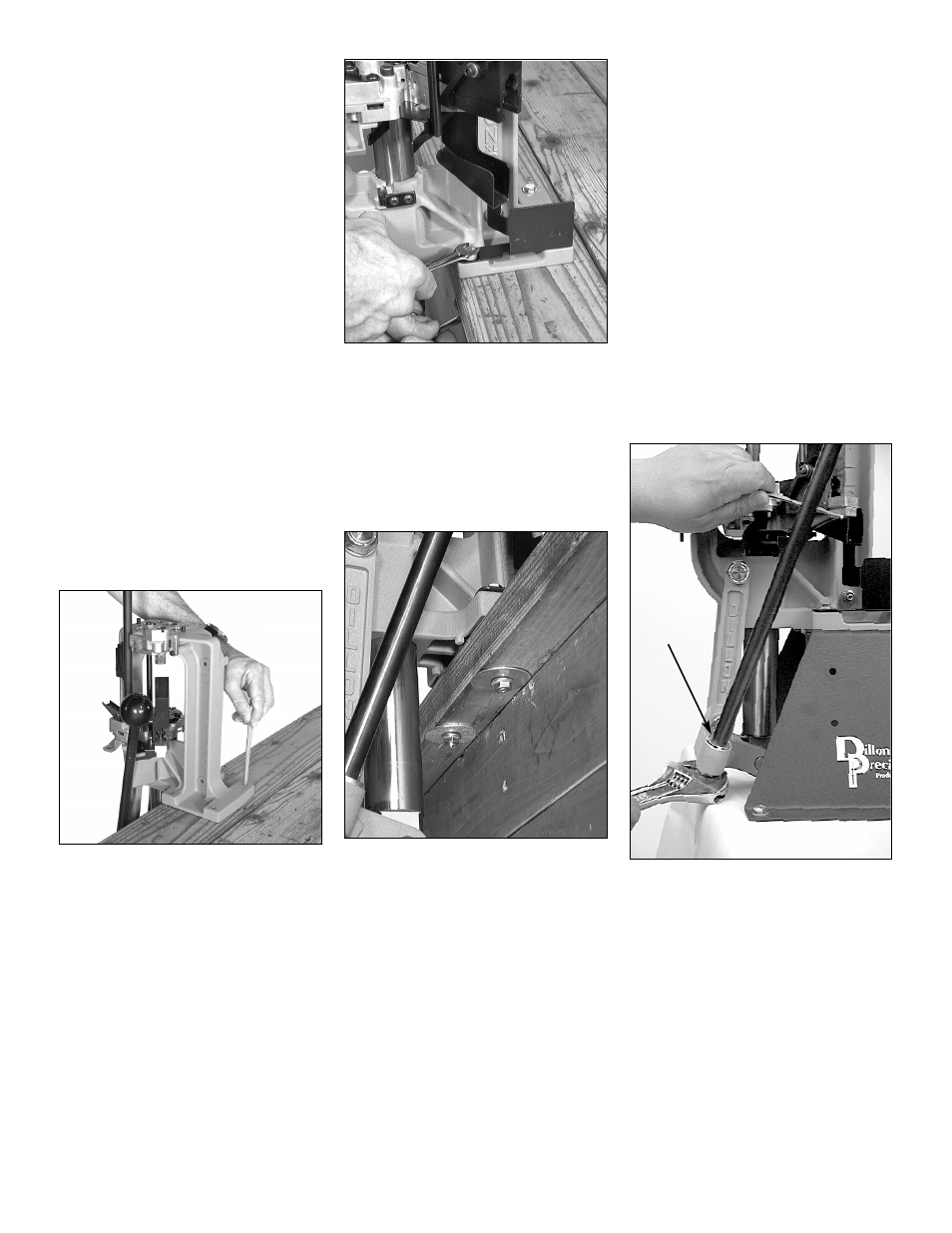

FIG 1

C. Drill the mounting holes FIG 1:

1. Using the machine as a template, mark

the four holes.

2. Using a 1/4” bit, drill the holes.

FIG 2

D. Bolting the machine to the

bench FIG 2:

Note: If you do not have a Mounting Hard-

ware Kit, ensure that you use 1/4”

or equivalent through bolts (with

large area washers if mounting to

wood). Do not use lag bolts or wood

screws!

FIG 3

1. Mount the left side of the machine with

the small washers on top and the large

washers on the bottom FIG 3. Run

the two left side nuts down finger tight.

2. Place the chute/bin bracket FIG 2 on

the right side of the machine. As

before, place the small washer on top

and the large washers on the bottom

and thread the nuts.

Note: The chute/bin mount goes under

the two right hand mounting bolts so

it must be installed as you are

mounting the machine FIG 2.

Check the fit of the chute/bin

mount. The chute/bin mount

should rest snugly against the

frame. Also, make sure that the

walls of the chute are parallel and

have not been bent during ship-

ping or installation.

3. Using two 7/16” wrenches, tighten all

four bolts down.

3. Initial Set Up

If you ordered your XL 650 for a specific

caliber, it comes factory adjusted for that

caliber (minus dies) with the appropriate

“caliber specific” parts included. In fact, a

Dillon technician runs casings and primers

through the machine to check its function.

Note: As you assemble your machine,

we recommend that you cross

check caliber specific parts, includ-

ed with your machine, with those

specified in the caliber conversion

chart (pages 42-44). The

point being – if we sent you the

wrong part, you’ll want to know it

before getting started. Reference

page 35 for instructions on how to

use the caliber conversion chart.

FIG 4

A. Installation of the handle FIG 4:

1. Hold the washer (see arrow FIG 4)

over the hole on the right side of the

crank and insert the handle.

2. Place a 5/32” Allen wrench or screw

driver through the hole in the handle to

help your grip.

3. Tighten the nut using a 7/8” wrench.