Dillon Precision XL 650 User Manual

Page 25

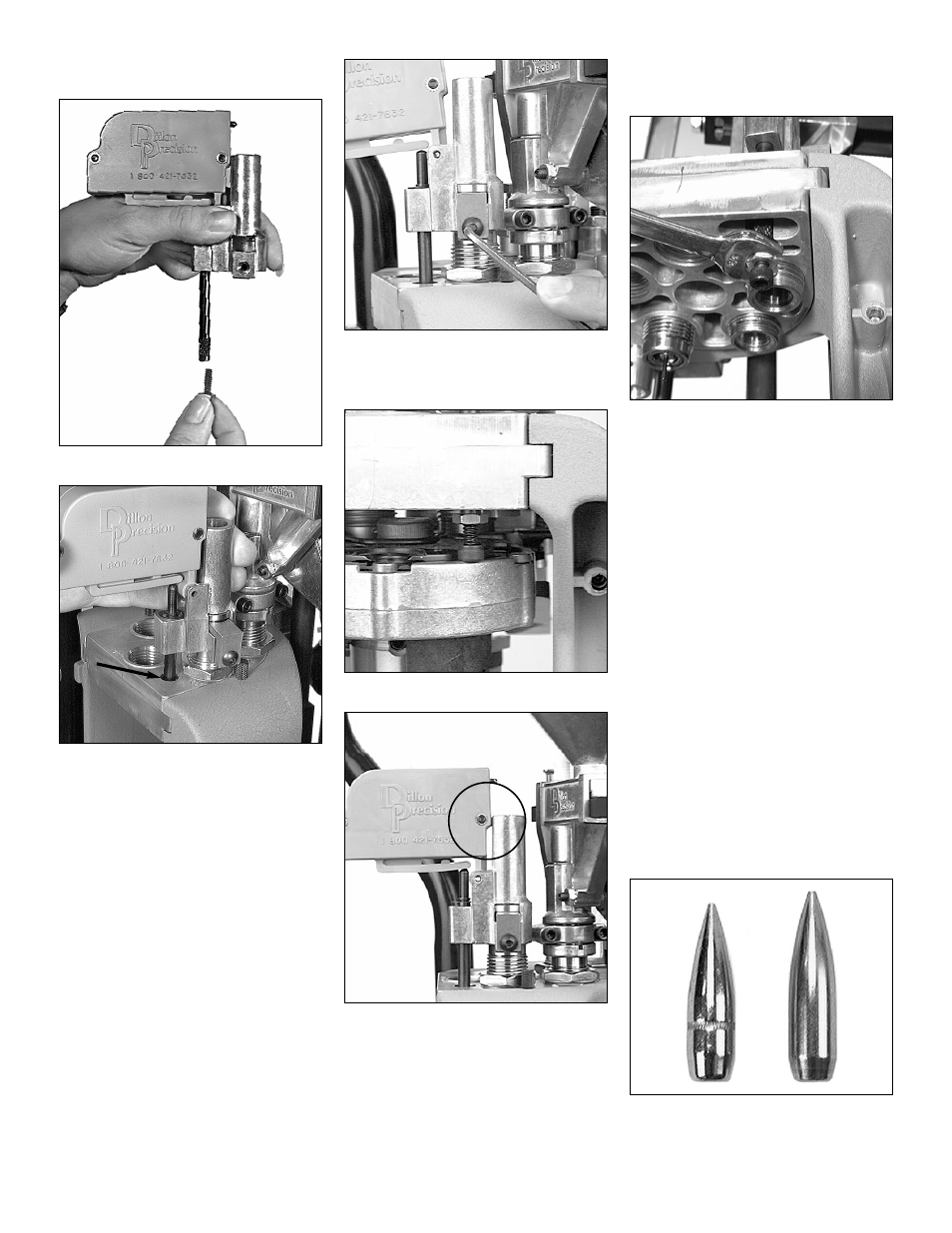

3. Run the lockring down. Using a 1-

1/8” wrench snug the lockring.

FIG 107

FIG 108

4. Remove the 10-24 screw and nut

from the black push rod FIG 107 and

place the powder check system on

the powder check die FIG 108.

Center the black push rod (see arrow

FIG 108) in the hole that is to the left

of the die.

FIG 109

5. Reinstall and snug the die clamp

screw FIG 109.

FIG 110

FIG 111

6. FIG 110 Screw the 10-24 screw and

nut fully into the rod. Raise the plat-

form. Unscrew the 10-24 screw

until it contacts the edge of the plat-

form FIG 110. Lower the platform

part way and unscrew the screw

(counter-clockwise) until raising the

platform causes the buzzer housing

to rock into the side of the die collar

FIG 111.

FIG 112

7. Secure the jam nut by holding the

black push rod while tightening it

using a 3/8” wrench FIG 112.

Note: Once you’ve adjusted the powder

bar for the desired powder charge –

installation and adjustment of the

powder check system can be com-

pleted.

J. Station 4 – How to deter-

mine the proper seating

depth:

Before installing and adjusting the seating

die you’ll need to know how to determine

the proper seating depth. How far the bullet

is seated into the case will determine the

overall length (OAL). Several factors go into

determining the proper OAL – such as, the

maximum recommended OAL, listed in the

reloading manual, and the type of bullet

being loaded. The type of bullet can deter-

mine the OAL by one of two ways. If the

bullet has what is called a cannelure, FIG

113, this will determine the proper OAL.

FIG 113

26