Now its time to start loading – Dillon Precision XL 650 User Manual

Page 33

Add some empty cases to your casefeeder

and turn the unit “on”. The motor will run

until the clear casefeed tube fills and then it

will automatically shut off.

The reloading process on an XL 650

begins with one complete stroke or cycle of

the handle, which causes the first case to be

cycled through the casefeed system and fed

into the shellplate.

Station One

The first case is at station one of the

machine and a new primer is ready at sta-

tion 2. Move the handle down, the sizing

die reforms and also deprimes the first case.

Return the handle to its rest position. Using

a smooth, fluid motion, move the handle up

to its full aft stop to seat the new primer into

the case and release the handle. At the

same time, another case has been fed into

the shellplate.

Station Two

Again, cycle the handle completely. The

first case now gets a charge of powder, the

second case is resized and deprimed, then

they both advance to the next stations.

Using a smooth, fluid motion, move the

handle up to its full aft stop to seat the

new primer into the case. Return the han-

dle to its rest position. Now three cases

are in the shellplate.

Station Three

Cycle the handle. The first case enters the

powder checker, the second case is charged

with powder and the third case is resized

and deprimed. Again, return the handle to

its rest position and all the cases advance to

their next stations and the fourth case is

inserted into the shellplate.

Station Four

It is now time to begin placing a bullet on

the case at station four. Cycle the handle

down and then back up to its rest position.

The first case now has a bullet seated into it

and has advanced to station five. At this

point the shellplate is full.

Seat a primer into a case at the full aft

stroke of the handle and a case is inserted

into the shellplate automatically.

Station Five

Using your left hand, place a bullet on the

case at station four. Cycle the handle and

the first case is crimped at station five and

then ejected out at the right rear of the

machine into the collection bin. Repeat the

process by placing a bullet into the case at

station four and seating the primer into the

case at station two.

At this point a completed round is ejected

from the machine with every complete

stroke of the handle.

When operating the handle, pay close

attention to the cases, noting the changes

that take place as they go through the

machine.

Pace yourself when operating the

machine. Do not crash the handle down

against its stop and do not snatch the han-

dle upward. It should take two or more

seconds to move the handle from its rest

position, down and then back up to its

rest position.

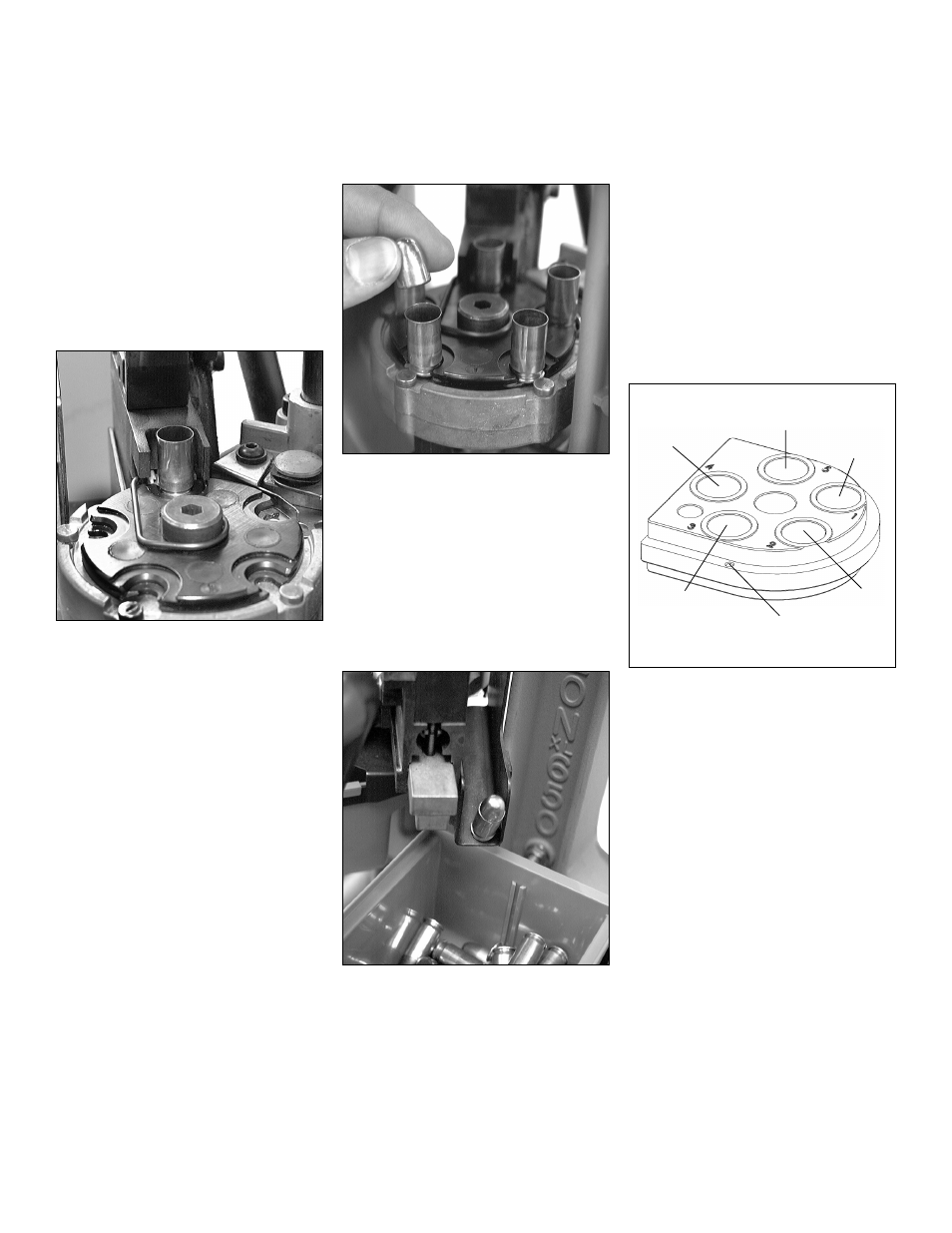

Station/Toolhead Orientation

34

Now its Time to Start Loading

Station Orientation and Loading Functions

Sta. 4

Seat Die

Sta. 5

Crimp Die

Sta. 1

Sizing Die

Sta. 2

Powder

Measure

Toolhead

Pin (2)

Sta. 3

Powder Check

System (optional)