Dillon Precision XL 650 User Manual

Page 13

14

and small powder bar, on the other hand,

are standard equipment and are included

with every XL 650. All powder measures

are shipped with small powder bars

installed . If you need to change the powder

bar – refer to “Powder Bar Adjustment” in

the Caliber Conversion Section on page 30.

E. Station 2 – Adjustment

of Powder Die & Powder

Funnel:

Note: Adjusting the powder die for a

straight wall case is not the same

as adjusting a powder die for a

bottle-necked case. This is

because straight wall cases are

given a bell and bottle-necked

cases are not given a bell.

Adjusting the powder die for a

bottle-necked case is covered in

the rifle section.

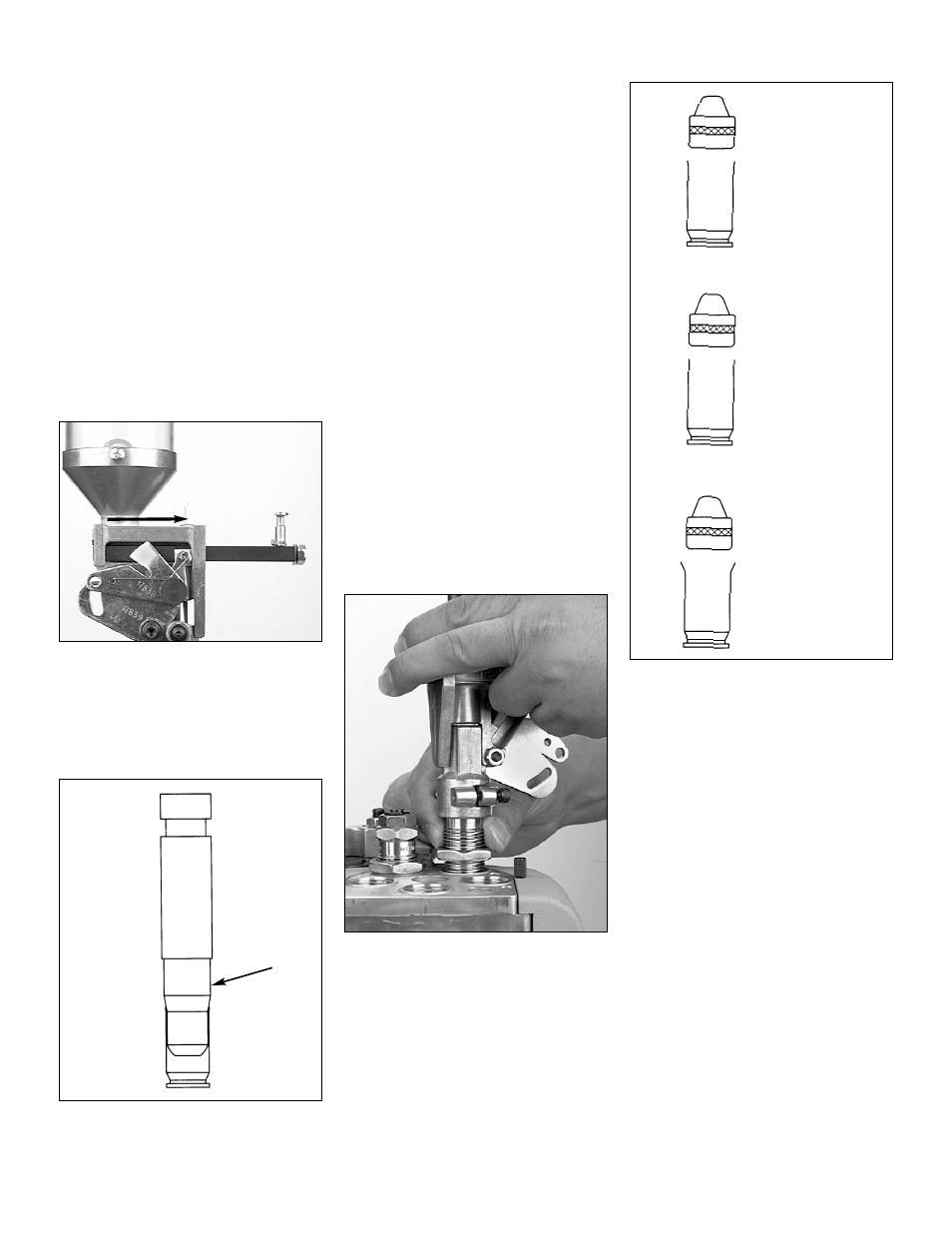

FIG 40

For the powder bar to properly dispense a

measured powder charge the powder bar

must travel its full distance. To travel its full

distance, the white cube must contact the

powder measure body (see arrow FIG 40).

FIG 41

Also the belling process does not begin until

after the powder bar has traveled its full dis-

tance. The angled portion on the bottom of

the powder funnel (see arrow FIG 41) is

what bells the cartridge. Once the white

cube has contacted the powder measure

body the case is forced upward against the

tapered portion of the powder funnel pro-

ducing a bell. The more the powder die is

adjusted down (clockwise) the more the

case will be belled.

Note: If the powder die is not adjusted

down far enough to cause the

powder bar to travel its full dis-

tance the powder charge will be

erratic and the case will not

receive enough bell.

To adjust the powder die/powder

funnel:

1. Drop a case into the casefeed funnel

and cycle the handle. The case

should now be in the shellplate at

Station 1.

2. Raise the platform. Notice the resis-

tance at the end of the downstroke.

This is the resistance of the case in

the sizing die. Lower the platform.

The case will index to Station 2.

3. Raise the platform. Check to see

how far the powder bar has traveled

FIG 40.

FIG 42

4. If the white cube has not traveled its

full distance, lower the platform just

enough to pull the case off of the

powder funnel (this will prevent the

shellplate from indexing while you

adjust the powder die). While holding

the powder measure, turn the die

down 1/8 of a turn FIG 42. Again

raise the platform and observe the

travel of the powder bar.

5. Repeat step four until the powder bar

travels its full distance FIG 40.

FIG 43

Once the powder bar travels fully across

you should continue to adjust the powder

die for the desired amount of bell (turn the

powder die 1/8 of a turn at a time). The

desired amount bell is just enough to allow

the bullet to sit on the case mouth without

falling off and to keep the case from shaving

lead during the seating process (see “A”

FIG 43).

Note: If you screw the die down too far,

the case will look like example “C”

FIG 43. You must then discard

this case, back the powder die off,

by turning it counter-clockwise, and

continue with a new sized case.

You’ll soon learn to judge the correct

amount of bell by simply looking at it. In

the meantime, you might want to use your

dial calipers to check it. Twenty thou-

sandths of an inch greater (at the mouth of

the case) than its original diameter, should

about do it.

A

Correct amount of

bell.

B

Not enough bell.

C

Too much bell.