Dillon Precision XL 650 User Manual

Page 26

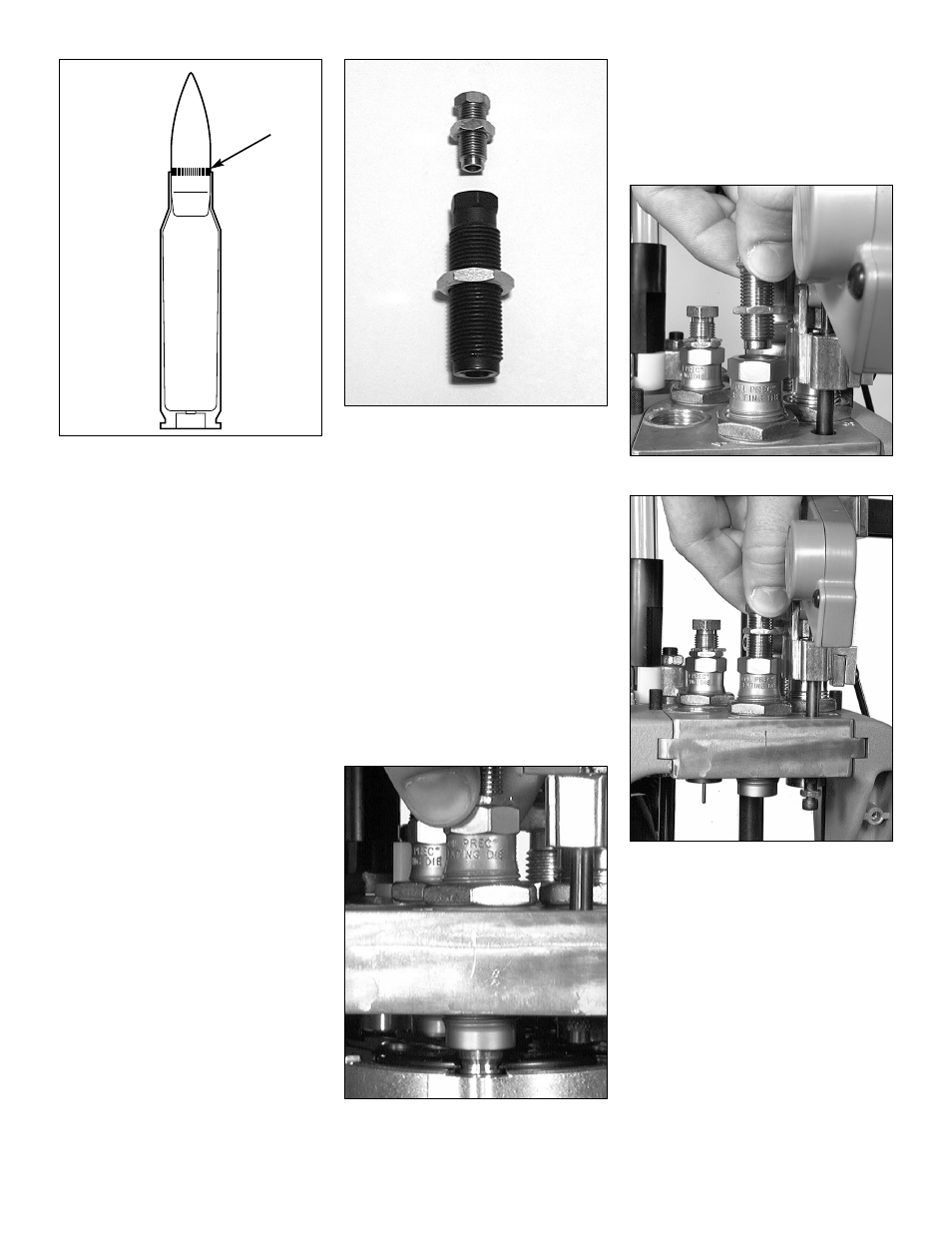

FIG 114

If the bullet you’re using doesn’t have a

cannelure, then you’ll need to refer to

your reloading manual for the suggested

OAL. The purpose of the cannelure is to

secure the bullet by giving the mouth of

the case something to dig into when being

crimped. When the bullet is properly

seated, the mouth of the cartridge case

should be in the middle of the cannelure,

see arrow FIG 114.

Refer to your reloading manual. Under

the section specified for the caliber you’re

loading, you’ll find a schematic of the car-

tridge. For example, .30-06 lists a maximum

OAL of 3.340” (Lyman Reloading

Handbook). If you’re seating the bullet to

the cannelure, the OAL should be well

within the maximum OAL listed, however,

use a set of dial calipers to check it. (Dial

calipers are available from Dillon

Precision). If the bullet you’re using doesn’t

have a cannelure, refer to its specific type in

the reloading manual. For example – if

you’re loading a .30-06 180 gr. JHPBT, and

it doesn’t have a cannelure, use the suggest-

ed OAL of 3.280 (Lyman Reloading

Handbook).

FIG 115

K. Station 4 – Seating Stem

for rifle FIG 115:

Unlike pistol seating dies, rifle seating dies

come with only one type of seating stem.

Dillon seating dies, which are being

used in this manual, are easily disassem-

bled. Should you need to disassemble the

rifle seating die – simply unscrew the seat-

ing stem from the top of the seating die

FIG 115.

L. Station 4 – Installation and

Adjustment of the

Seating Die

1. Place a lubricated sized case into

Station 4 and raise the platform.

FIG 116

2. Thread the seating die into Station 4.

Continue to screw it down until it

contacts the case FIG 116. Once the

die is in contact with the case back

the die off (counter-clockwise) 1/4 of

a turn. Using a 1” wrench snug the

lockring on the seating die.

FIG 117

FIG 118

3. Lower the platform.

4. FIG 117 Back the seating stem all the

way out of the seating die. Now

screw the seating stem back into the

seating die two full turns FIG 118.

5. Place a bullet on the case mouth and

raise the platform – then lower the

platform just enough to inspect the

bullet without indexing the shellplate.

a. If the bullet is not pushed down far

enough – go to step 6.

b. If the bullet is pushed down too far:

b.1. Pull the bullet from the case

using a Dillon bullet puller.

b.2. Back the seating stem out by

;;

;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

27