Dillon Precision XL 650 User Manual

Page 14

15

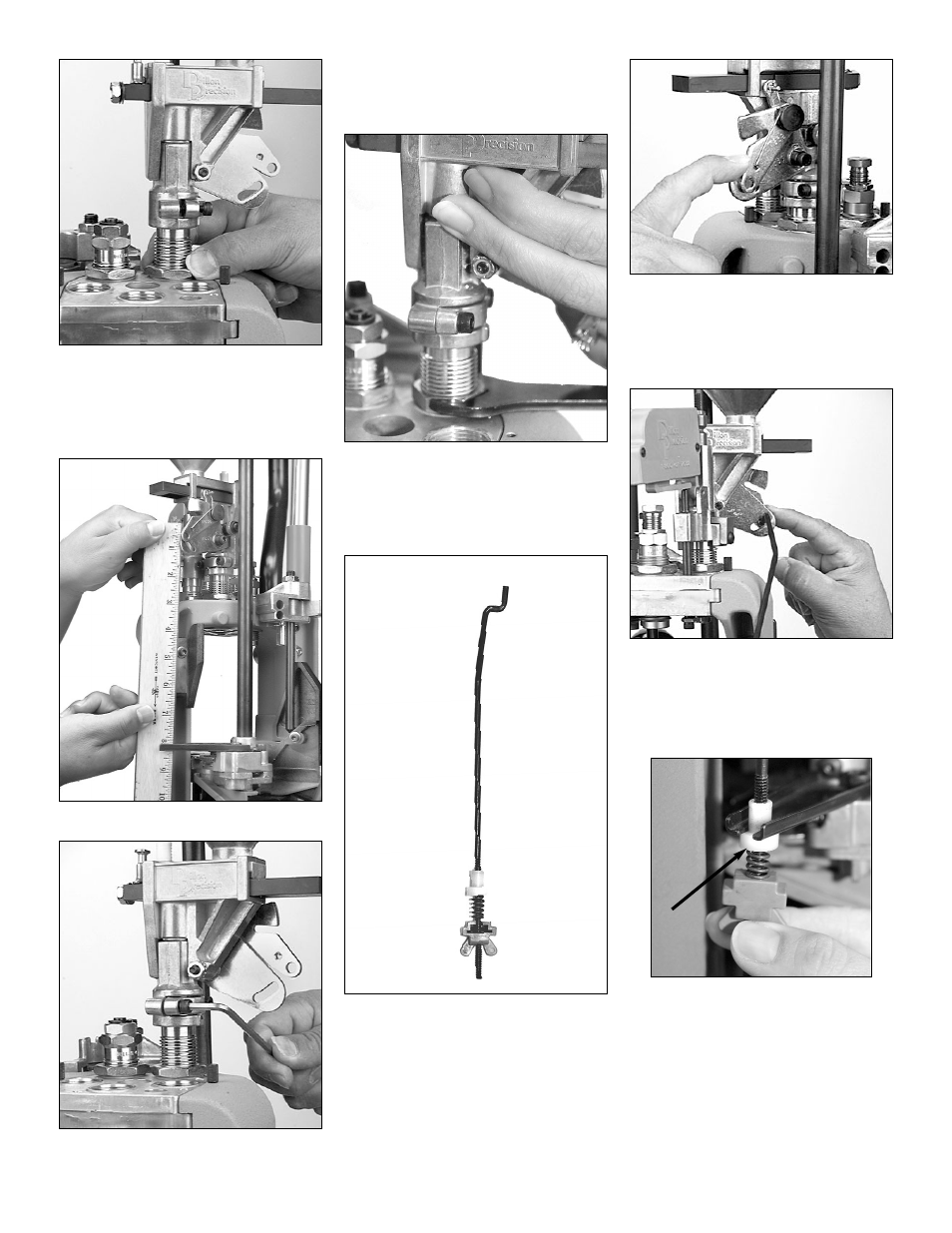

FIG 44

6. Once you’ve achieved the desired

amount of bell – with the case in

Station 2, raise the platform. Run the

lockring down hand tight FIG 44.

FIG 45

FIG 46

7. Insure the bellcrank and the failsafe

bracket FIG 45 are aligned. Using a

5/32” Allen wrench, snug the collar

clamp screws FIG 46.

FIG 47

8. While holding the powder mea-

sure, snug the lockring using a 1

1/8 wrench FIG 47. Now lower the

platform.

FIG 48

F. Station 2 – Installation of

the failsafe rod assembly

FIG 48:

The purpose of the powder measure fail-

safe rod is to return the powder bar to its re-

charge position.

FIG 49

1. Using your forefinger, move the lock-

link (#17838) down to align the hole

with the slot on the Powder Measure

bellcrank (#97034) FIG 49.

FIG 50

2. Insert the rod (#13629) through the

holes FIG 50.

3. Loosen the blue plastic wing nut

(#13799).

FIG 51

4. Slide the failsafe rod into the failsafe

return bracket. Push the shoulder

washer up into place (arrow FIG 51)

and tighten the blue plastic wing nut

until the end of the threaded rod is

even with the wings of the wing nut.

Note: Do not fill the powder measure or

adjust the powder bar until the rest

of the dies are installed and adjusted.