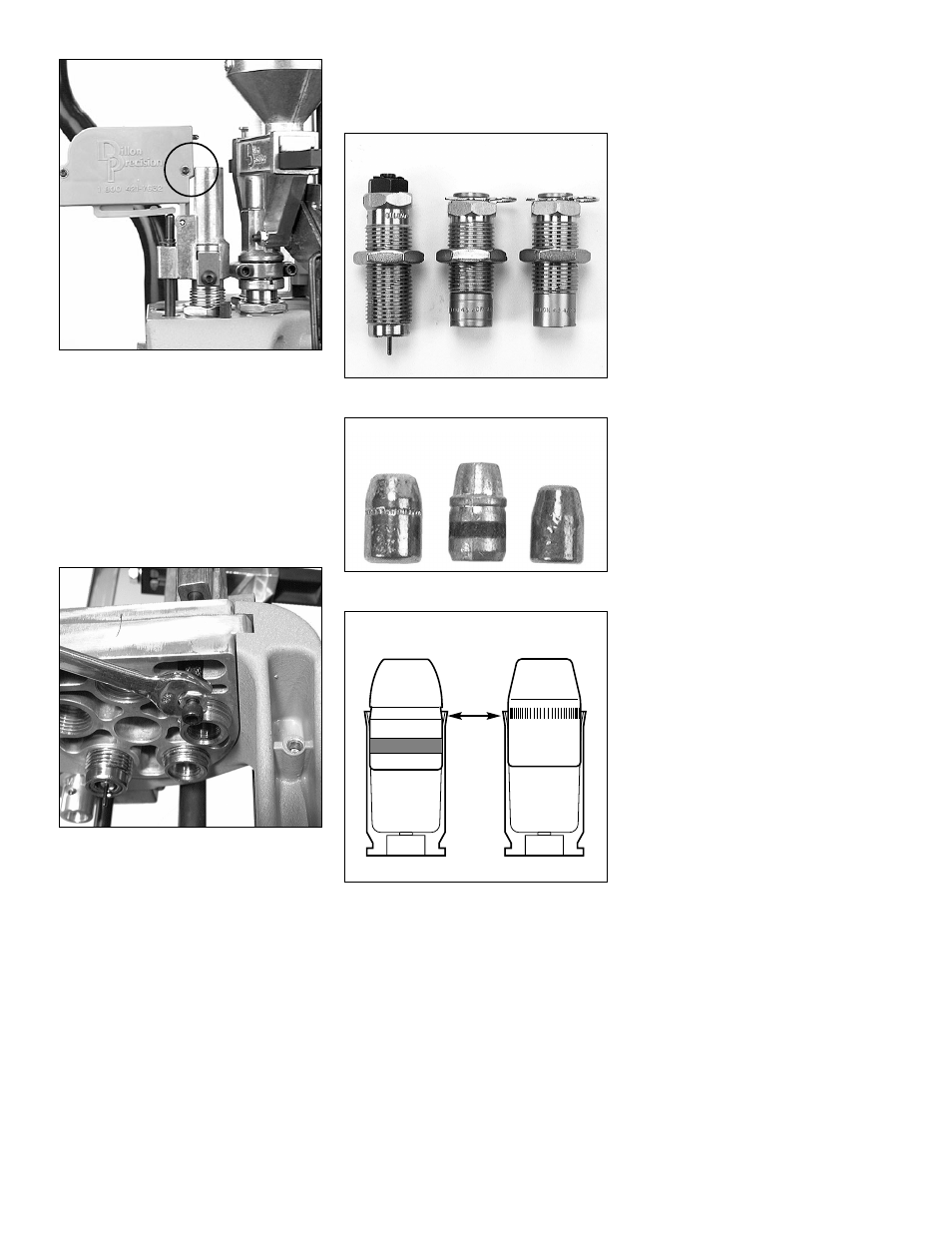

Fig 60, Fig 61, Sizing/decapping die seating die crimp die – Dillon Precision XL 650 User Manual

Page 16

17

FIG 60

6. FIG 59 Screw the 10-24 screw and

nut fully into the rod. Raise the plat-

form. Unscrew the 10-24 screw until

it contacts the edge of the platform

FIG 59. Lower the platform part way

and unscrew the screw (counter-

clockwise) until raising the platform

causes the buzzer housing to gently

rock into the side of the die collar

FIG 60.

FIG 61

7. Secure the jam nut by holding the

black push rod while tightening it

using a 3/8” wrench FIG 61.

Note: Once you’ve adjusted the powder

bar for the desired powder charge,

adjustment of the powder check

system can be completed.

H. Station 4 – General

Information on Bullet

Seating

FIG 62

FIG 63

FIG 64

The purpose of the seating die FIG 62 is

to insert the bullet into the case and to push

it down into the case the proper amount.

How far the bullet is pushed into the case

will determine the overall length (OAL).

Several factors go into determining the

proper OAL – such as, the maximum rec-

ommended OAL, listed in the reloading

manual, and the type of bullet being

loaded. The type of bullet can determine

the OAL in one of two ways. If the bullet

has what is called a cannelure, or crimping

groove (items A&B in FIG 63), this will

determine the proper OAL. If the bullet

you’re using doesn’t have a cannelure or a

crimping groove (item C in FIG 63), then

you’ll need to refer to your reloading manu-

al for the suggested OAL. The purpose of

the cannelure and crimping groove is to

secure the bullet by giving the mouth of the

case a place to go (without deforming the

bullet) when being crimped. When the bul-

let is properly seated, the mouth of the car-

tridge case should be near the top of the

cannelure/crimping groove FIG 64.

Refer to your reloading manual. Under

the section specified for the caliber you’re

loading, you’ll find a schematic of the car-

tridge. For example, .38 Special lists a max-

imum OAL of 1.55” (Lyman Reloading

Handbook). If you’re seating the bullet to

the cannelure/crimping groove, the OAL

should be well within the maximum OAL

listed, however, use a set of dial calipers to

check it. (Dial calipers are available from

Dillon Precision). If the bullet you’re using

doesn’t have a cannelure/crimping groove,

refer to the specific type of bullet you’re

using in the reloading manual. For example

– if you’re loading a 158gr 38sp JHP and it

doesn’t have a cannelure/ crimping groove,

use the suggested OAL of 1.480 (Lyman

Reloading Handbook).

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;

;

;;;;;

;;;;;

;;;;;

;;;;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;

;

;;;;;

;;;;;

;;;;;

;;;;;

A

Sizing/Decapping Die

Seating Die Crimp Die

B

C