Dillon Precision XL 650 User Manual

Page 22

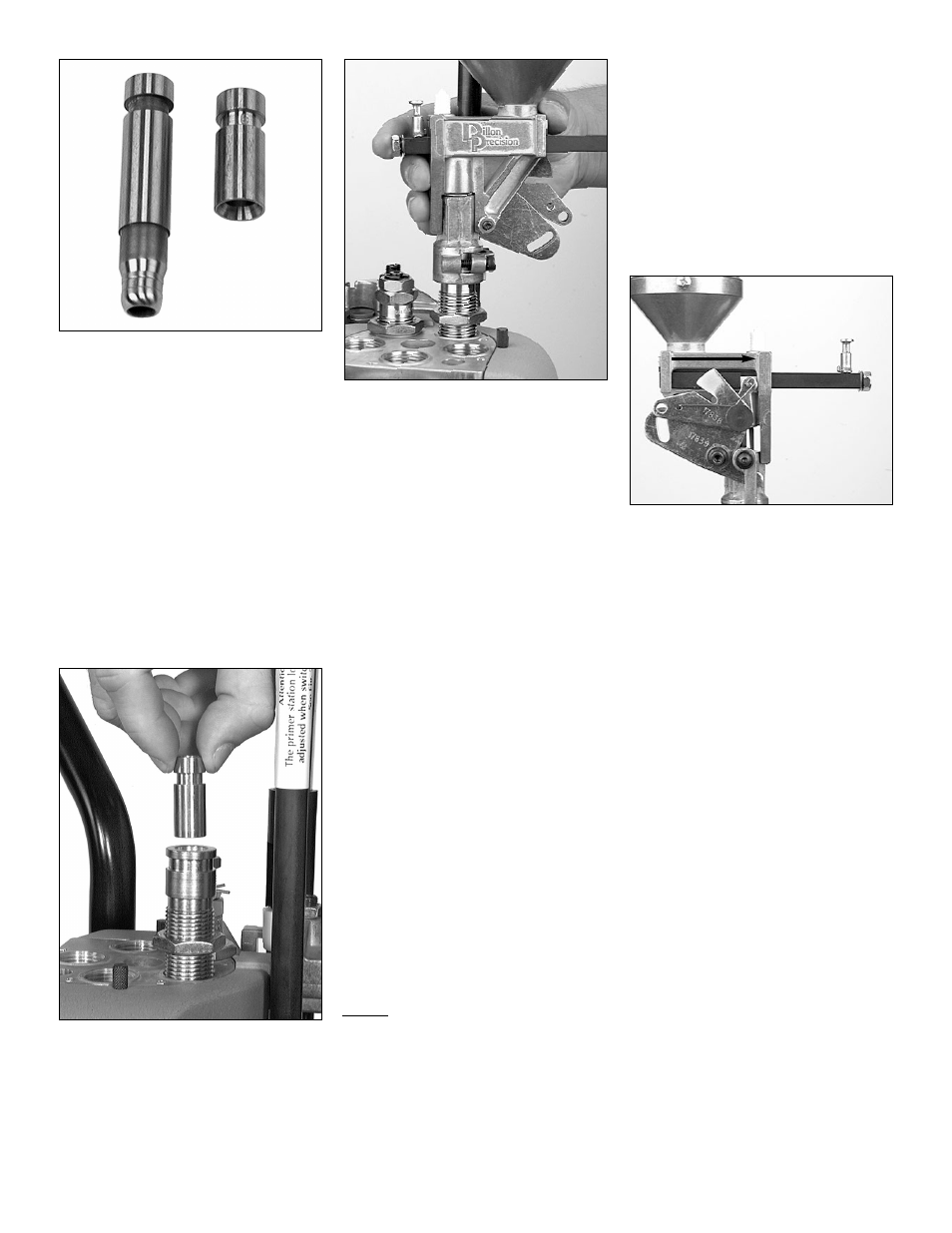

FIG 90

In FIG 90 are two examples of the many

powder funnels available for the XL 650.

On the left is a typical pistol caliber fun-

nel. On the right, a rifle or bottle-necked

type. The bottom of the rifle style funnel

fits snugly over the neck of the case allow-

ing powder to drop in without spilling (the

rifle style powder funnel does not bell the

mouth of the case). The bottom of the pis-

tol funnel, on the other hand, fits inside

and actually expands the case mouth as it

guides the powder into the case (the

expansion of the case mouth is where the

mouth of the case gets its bell). Powder

funnels are caliber specific so be sure you

have the correct funnel by referring to the

caliber conversion chart.

FIG 91

4. Insert the funnel into the die FIG 91.

Regardless of whether you’re using a

rifle or pistol powder funnel, make

sure that you insert the funnel into the

die with the grooved end up. It

should move up and down freely.

FIG 92

5. Remove the lid and the protective

cardboard tube from the powder mea-

sure and place it onto the powder die

FIG 92. Turn down the two clamp

screws until they are snug. Then

loosen them slightly. The measure

should move freely atop the die.

F. Station 2 – About powder

bars:

Dillon Precision manufactures four types

of powder bars for the XL 650:

1. Extra Small – use for dropping less

than 3 grains of powder.

2. Small – use for dropping 3 to 10

grains of powder.

3. Large – use for dropping 10 to

approx. 45-50 grains of powder.

4. Magnum – use for dropping more

than approx. 45-50 grains of powder.

The extra small powder bar is used when

loading .32 Auto, .32 S&W and .32 SWL.

Both the extra small powder bar and the

magnum powder bar are non-standard

items and are ordered separately. The large

and small powder bar, on the other hand,

are standard equipment and are included

with every XL 650. All powder systems

come from the factory with the small pow-

der bar installed. If you need to change out

the powder bar – refer to “Station 2 –

Changing out the Powder Bar” page 41,

Step 19.

G. Station 2 – Adjustment

of Powder Die/Powder

Funnel

Important: Adjusting the powder die for a

bottle-necked case is not the same

as adjusting the powder die for

straight-walled cases. This is

because bottle-necked cartridges

are not given a bell – straight-

walled cases are given a bell. For

straight-walled cartridges refer to

the pistol section.

FIG 93

For the powder bar to properly dispense a

measured powder charge, the powder bar

must travel its full distance. To travel its full

distance, the white cube must contact the

powder measure body (see arrow FIG 93).

When adjusting the powder die for a

bottle-necked cartridge, the objective is to

adjust the powder die so that the powder

bar just travels the full distance and no

further (see arrow FIG 93). If you try to

apply the procedures used for belling a

straight walled case, as when loading pis-

tol cartridges, you will crush the bottle-

necked case and possibly damage the

powder measure.

Note: If the powder die is not adjusted

down far enough to cause the pow-

der bar to travel its full distance the

powder charge will be erratic.

Note: Whenever sizing a bottle-necked

case you must lubricate the case

first, otherwise you will stick the

case inside the sizing die. For

more information refer to the section

“Lubricating Your Brass” (page 11).

23