Dillon Precision XL 650 User Manual

Page 20

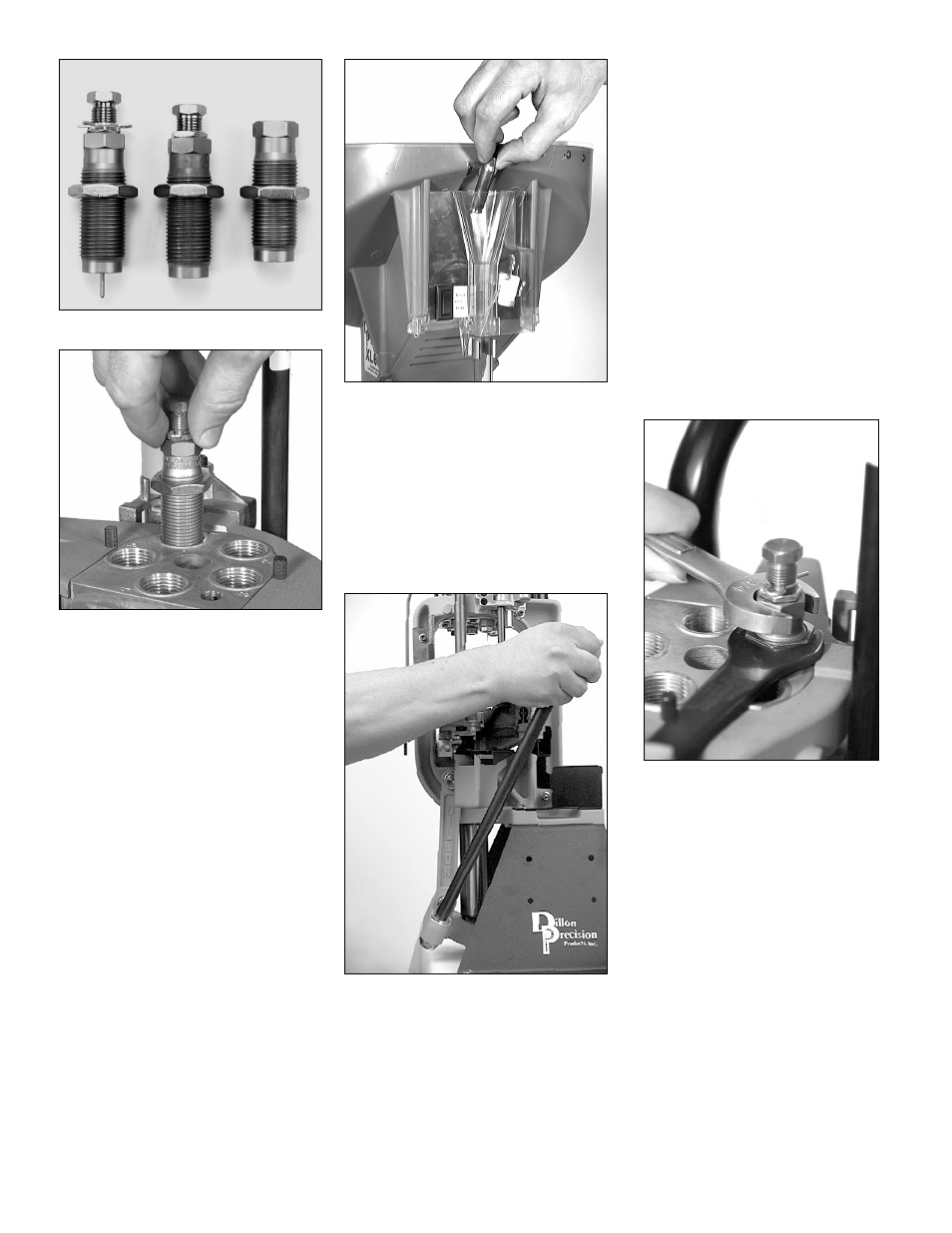

FIG 78

FIG 79

C. Station 1 – Installation

and adjustment of the siz-

ing/decapping die FIG 78:

Warning: Never attempt to de-prime a live

primer, an explosion may result

causing serious injury or even

death.

Note: Whenever sizing a bottle-necked

case you must lubricate the case

first, otherwise you will stick the

case inside the sizing die. For

more information refer to the section

“Lubricating Your Brass” (page 11).

1. Raise the platform, by lowering the

handle all the way.

2. Install the sizing die by screwing it

into Station 1 FIG 79. Continue to

screw the die down until the mouth

of the die is about the thickness of a

dime away from the shellplate. Lower

the platform by raising the handle to

its upright position.

FIG 80

3. Drop a lubricated case into the case-

feed funnel FIG 80. Here the case

drops to the casefeed arm bushing.

4. Raise the platform. The inserter cam

pushes the feed arm bushing over the

body, dropping the case onto the

Station 1 locator.

5. Lower the platform. The case is

inserted into Station 1.

FIG 81

Note: After raising the handle, insure that

you push the handle against its full

aft stop FIG 81. This will insure

that the case is fully inserted into

Station 1.

Note: When priming, pushing the handle

against its full aft stop will insure

that the primer is fully seated.

6. Again raise the platform. The case is

now sized. If the case has a spent

primer, it will be deprimed. Notice

the resistance at the end of the

downstroke. This is the resistance of

the case in the sizing die. Lower the

platform. The case will index to

Station 2.

7. Remove the case from Station 2 and

place it in the case gage. From this

point – follow the instructions provid-

ed under “Rifle Section B. Station 1 –

How to use the Case Gage.”

8. Once the sizing die is properly

adjusted, replace the case into Station

1 and raise the platform. Leave the

platform in the raised position with

the case fully inserted in the die. This

will ensure that the die remains in

position when tightening the lockring.

FIG 82

9. Run the lockring down until it con-

tacts the toolhead. Using a 1” wrench

to turn the lockring and a 3/4”

wrench to hold the die body, snug

the lockring FIG 82.

21

Sizing/Decapping Die

Seating Die

Crimp Die