Dillon Precision XL 650 User Manual

Page 31

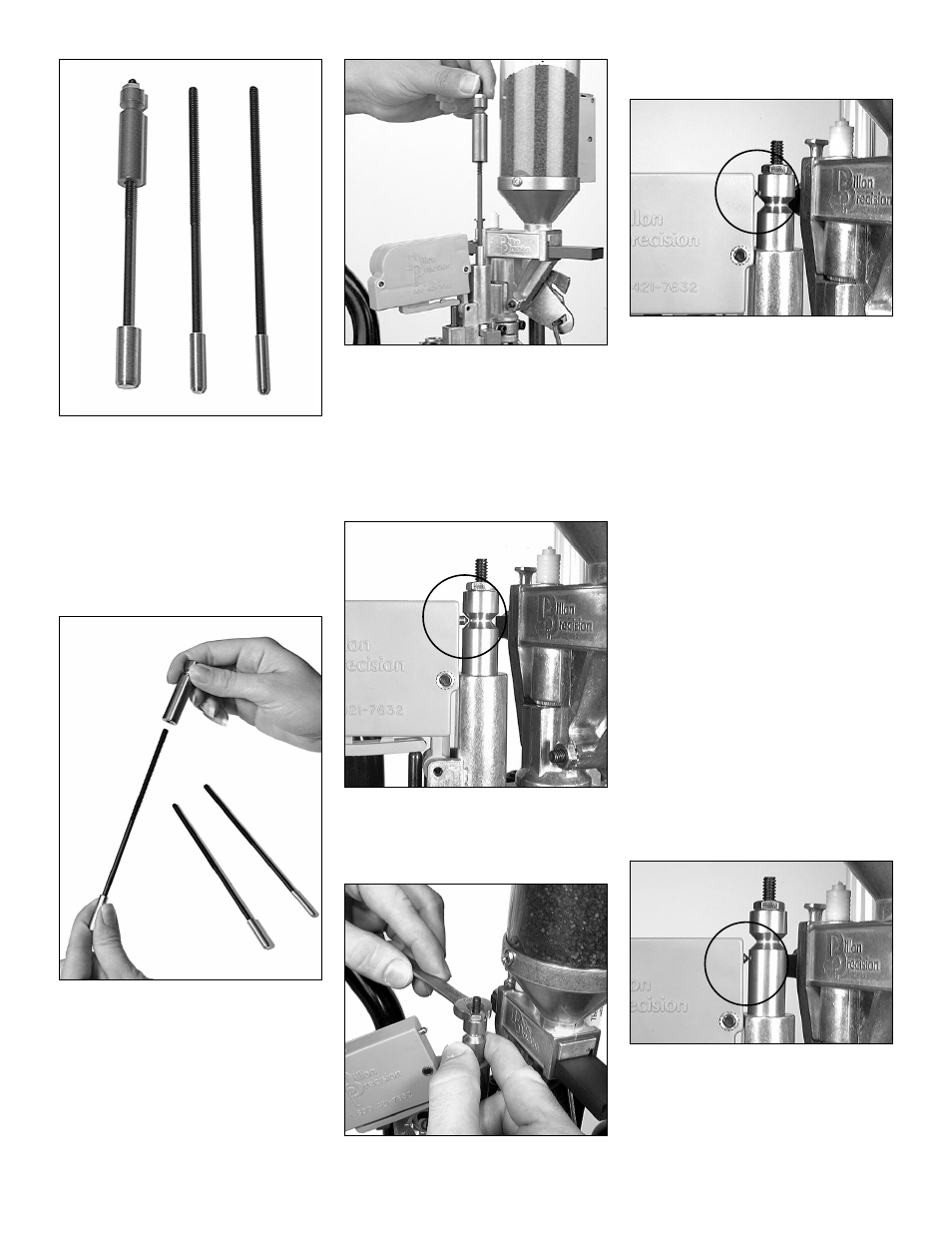

FIG 139

A. Installation and adjustment of

the powder check rods

FIG 139:

1. Remove the powder check rods from

the bag FIG 139. The three rods fit

different calibers. On the left .44-.45

caliber, center .30-.41 caliber and on

the right .22-.29 caliber.

FIG 140

2. Choose the correct rod for the caliber

you’re loading. For example – if

you’re loading .38 Spl. you would

use the .30-.41 caliber rod. If the rod

you’re using doesn’t have the

grooved sleeve on it, remove the

grooved sleeve from the one you’re

not using and thread it onto the cor-

rect rod FIG 140.

FIG 141

3. Insert the rod into the powder check

die FIG 141.

4. Put on your safety glasses.

5. Place a case with the proper powder

charge into Station 3 and raise the

platform. Leave the platform in the

raised position.

FIG 142

6. Thread the grooved sleeve down so

that the contact pin fits inside the

groove as seen in FIG 142.

FIG 143

7. Snug the lock nut with a 3/8” wrench

FIG 143.

FIG 144

B. Powder Check System

Demonstration:

1. Place a primed but empty case (case

with no powder) into Station 3 and

raise the platform. The contact pin is

above the groove FIG 144 (the alarm

sounds) indicating that the case has a

low or no charge.

2. Lower the platform. Remove the

empty case from Station 4 and place

it in Station 2.

3. With the empty case in Station 2 give

it a double charge.

To do so:

a. Raise the platform all the way to

charge the case.

b. Lower the platform halfway (enough

for the powder bar to return to its start-

ing point without indexing the case to

Station 3 and releasing the locklink).

c. Again, raise the platform to give the

case a second charge of powder.

d. Index the case to Station 3 by lower-

ing the platform all the way. (The case

is now double charged and ready to be

checked by the Powder Check System.)

FIG 145

4. Raise the platform FIG 145. The con-

tact pin is below the groove (the

alarm sounds) indicating that the

powder charge is double or more.

32