Dillon Precision XL 650 User Manual

Page 27

turning it counter clockwise and try

again.

6. Screw the seating stem down 1/2 turn

at a time FIG 118.

FIG 119

7. Repeat as necessary until the correct

overall length is achieved. Use a dial

caliper or equivalent to measure the

overall length of the cartridge FIG

119. Check the overall length of the

round against the information in your

reloading manual.

FIG 120

8. Once you have obtained the proper

OAL, replace the cartridge into

Station 4, raise the platform and

snug the lockring on the seating stem

FIG 120.

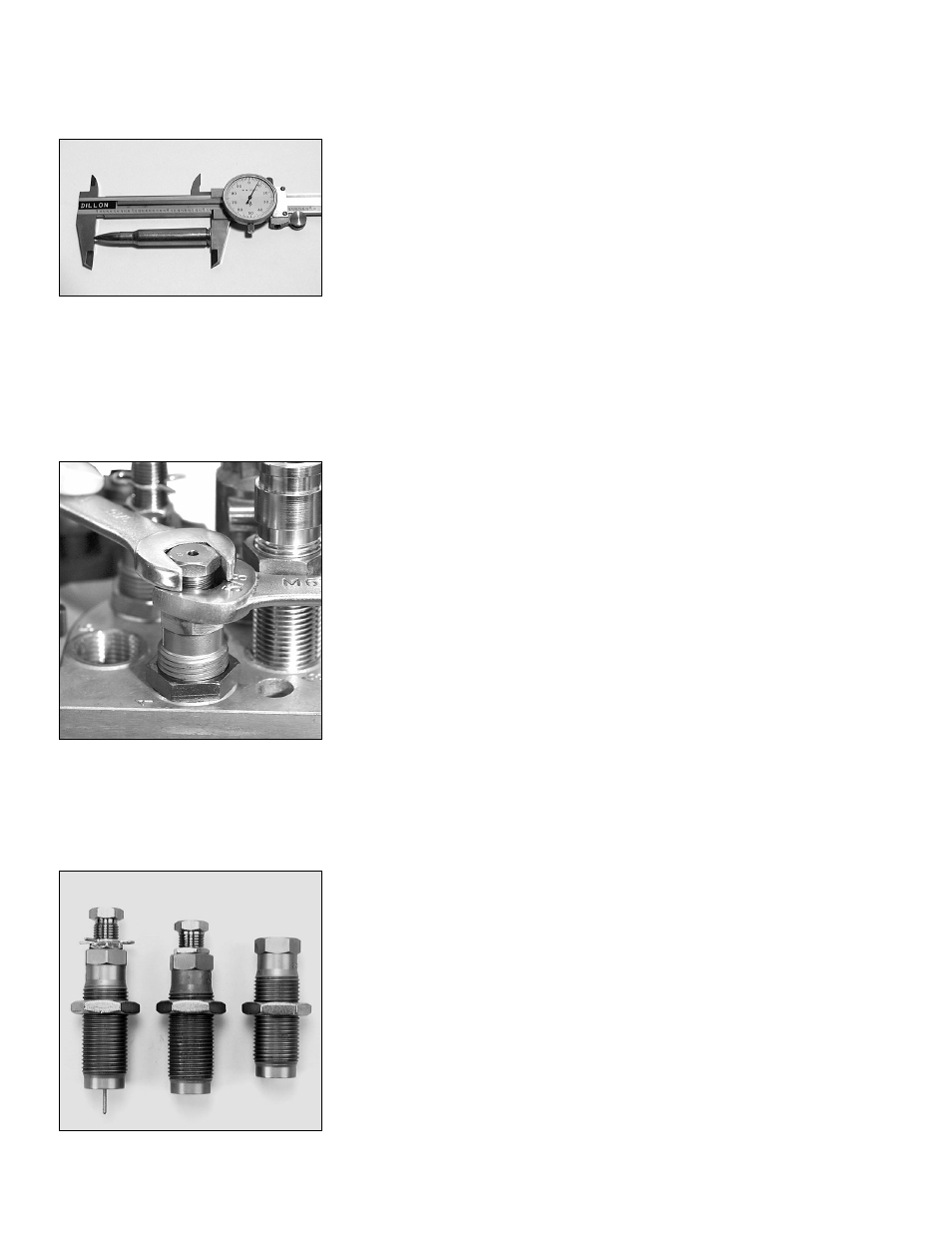

FIG 121

M.Station 5 – Installation and

adjustment of the Crimp

Die FIG 121:

1. Screw the crimp die into Station 5.

Screw it down until it is flush with the

bottom of the toolhead. This is a good

starting point for the crimp adjust-

ment.

2. Place a lubricated cartridge with a

properly seated bullet into Station 5.

3. Raise the platform and continue to

screw the die down until it stops.

4. Lower the platform and give the die a

half turn down; again, raise the plat-

form.

5. Lower the platform halfway and

inspect the cartridge. If the desired

amount of crimp has not been

achieved, give the die a 1/4 turn

down and try again. Continue making

small adjustments to your crimp die

until the desired amount of crimp has

been achieved.

6. Once the adjustment is complete,

place the case back into Station 5 and

raise the platform. Using a 1” wrench

to turn the lockring and a 7/8”

wrench to hold the die body, snug

the lockring.

Go to Loading Components

Section - Page 30

28

Sizing/Decapping Die

Seating Die

Crimp Die