Lubricating brass, Toolhead overview – Dillon Precision XL 650 User Manual

Page 10

11

Note: One end of the casefeed tube is

beveled and one end is squared off.

Insert the squared end of the tube

(down) into the top of the casefeed

adapter.

FIG 24

6. Using A 5/32” Allen wrench, snug

the machine screw against the case-

feed mounting post FIG 24 to pre-

vent the casefeed bowl from rotat-

ing.

4.Toolhead Overview

You’re now ready to install the toolhead

and adjust the dies. But first, we’ll give a

brief overview of the location and function

of each station, we’ll then follow up with a

detailed illustration.

FIG 25

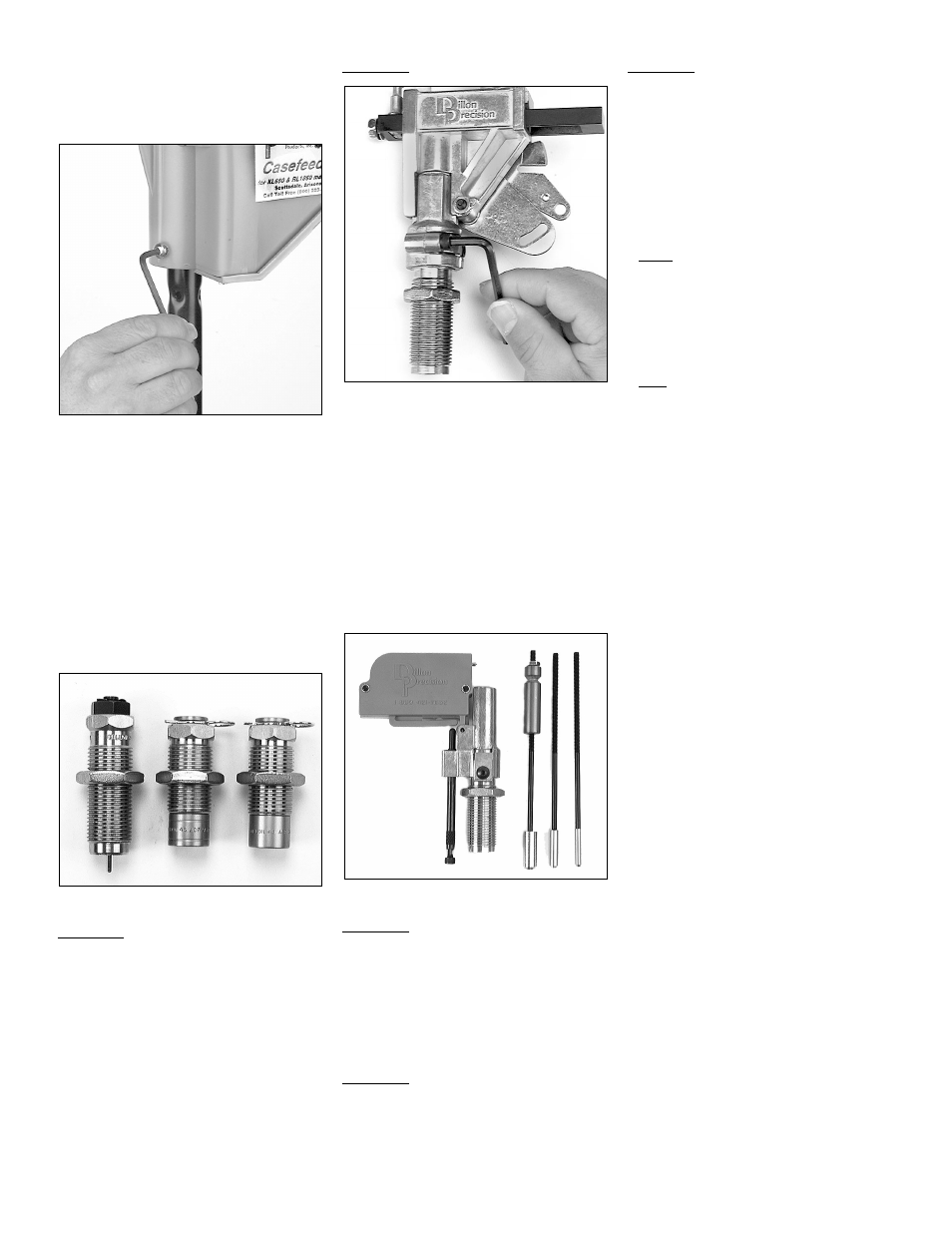

Station 1 - Sizing/Decapping

The stations on the toolhead are num-

bered 1-5. Station 1 is for the sizing/decap-

ping die FIG 25. This die can be easily

identified by the decapping pin sticking out

the bottom as well as by its label. This die

removes or “decaps” the old primer and

resizes the case.

Warning: Never decap live primers! (See

mandatory safety procedures.)

Station 2 - Powder Measure

FIG 26

Station 2 is for the powder die, which

comes attached to the powder measure

FIG 26. Here several operations are con-

ducted. The case is primed, straightwalled

pistol cases are belled, and powder is

dropped. The purpose of the bell at the

mouth of the case is simply to help align

the bullet and to keep the case from shav-

ing lead during the seating process. Note:

Only straight-walled cases receive a bell,

bottle-necked cases (rifle cartridges) are

not belled.

FIG 27

Station 3 - Powder Check

Station 3 is used for the optional powder

check system FIG 27. This system is located

in a separate package and can be identified

by the blue warning buzzer attached to a

die. This system is designed to detect gross

deviations in the powder charge, i.e. a dou-

ble charge of powder or no powder at all.

Station 4 - Bullet Seating

Station 4 is for the seating die FIG 25.

This is where the bullet is pushed into the

case.

Station 5 - Crimp

Station 5 is for the crimp die FIG 25. This

die not only removes the bell created at

Station 2, but rolls the mouth of the case

inward to insure proper feeding and to

secure the bullet.

LUBRICATING BRASS

To lubricate brass, use “Dillon Case

Lubricant” (item# 13733).

Pistol – If you’re using a carbide sizing

die, you will not need to lubricate your

cases (before sizing) when loading straight-

walled cases. If you’re not using a carbide

sizing die, you must lube the brass before

sizing. We do, however, recommend lubri-

cating all brass.

Rifle – Lubricate all bottle-necked cases,

even if you’re using a carbide sizing die.

To lubricate your cases, start by ensur-

ing that they are clean. Place your clean

brass in a shallow box so the cases are lay-

ing on their side. Pump a couple of sprays

of Dillon Case Lubricant over the cases.

Shake the box so the cases will tumble and

roll. Repeat this process again making sure

that the lubricant is well distributed over the

cases.

Note: When loading rifle cartridges, if your

sizing die doesn’t have a carbide

case mouth expander, you may

want to allow a little bit of lube to get

inside the case mouth.

Note: When loading bottle-necked

cartridges, if you get an excessive

amount of lube on the shoulder of

the case, it will leave oil dents.

Regardless of whether you’re lubri-

cating pistol or rifle cases – do not

drench the cases in lubricant. A light

film of lubricant is sufficient.

Toolhead Head Setup:

Pistol – go to page 12

Rifle – go to page 20