Storage, Location, Space requirements and clearance – Carrier 30HH User Manual

Page 6: Adequate floor strength, Vibration isolation, Moving and placing unit, Moving, 30hh,hj, Installation

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

30HH,HJ

INSTALLATION

PRELIMINARY SURVEY

Before

installation

is

started,

a

survey

should

be made to establish the procedures and ma

terials

required

by

installation

personnel.

See

cover picture for typical unit.

Storage

Because of the sensitive control mechanisms and

electrical

devices

incorporated

in

the

30HH,HJ

units, they should not be exposed to the weather.

Location

Always locate the unit indoors. In order to pre

vent freezing, the unit must be located in a space

where the temperature is at least 40 degrees.

Space Requirements and Clearance

Dimensions for the units are given in Table 1.

These

dimensions

are

useful

in

checking

door

clearances for moving the unit in and for deter

mining space requirements. A clearance of 2 to

3 feet should be left on each side and on the ends

for

piping

and

electrical

connections

and

also

to

facilitate

service

operations.

Clearance

at

one end of the unit, equal to the length of the

unit, for servicing and removal of chiller tubes

must be provided.

Adequate Floor Strength

Approximate weights of units are given in Table

1.

Make certain that the floor is strong enough

to support this weight. If necessary, add sup

porting

structure

to

the

floor

for

transferring

weight to the nearest beams. This can be done

with steel beams or reinforced concrete slabs.

Vibration Isolation

Rubber-in-shear

vibration

insulators

and

muf

flers

are

installed

on,

or

furnished

with,

the

compressors

of

all

units

beginning

with

early

1961

production.

The

inter-connecting

piping

must

be

sufficiently

flexible

to

prevent

vibra

tion

transmission,

if

vibration

still

exists,

vi

bration isolators may be used on the unit itself.

The

field-purchased

vibration

mountings

should

be placed under each corner of the package. The

weight

distribution

of

all

packages

except

the

30HH015 and 30HJ015 is such that each corner

mounting

supports

one

fourth

of

the

operating

weight. The weight distribution of the 30HH015

and 30HJ015 units is 55-45 side to side and sym

metrical front to back.

All phases of vibration isolation are fully de

scribed in Section 5X-1 of the Product Infor

mation book. Consult same for best results.

For

additional

information

see

"Compressor

Mounting."

MOVING AND PLACING UNIT

Moving

The skids on which the unit is mounted should

not be removed until the unit is at the final loca

tion. When handling the unit with a chain hoist,

remove the panels so that they will not be dam

aged by the sling. Do not attach the sling to

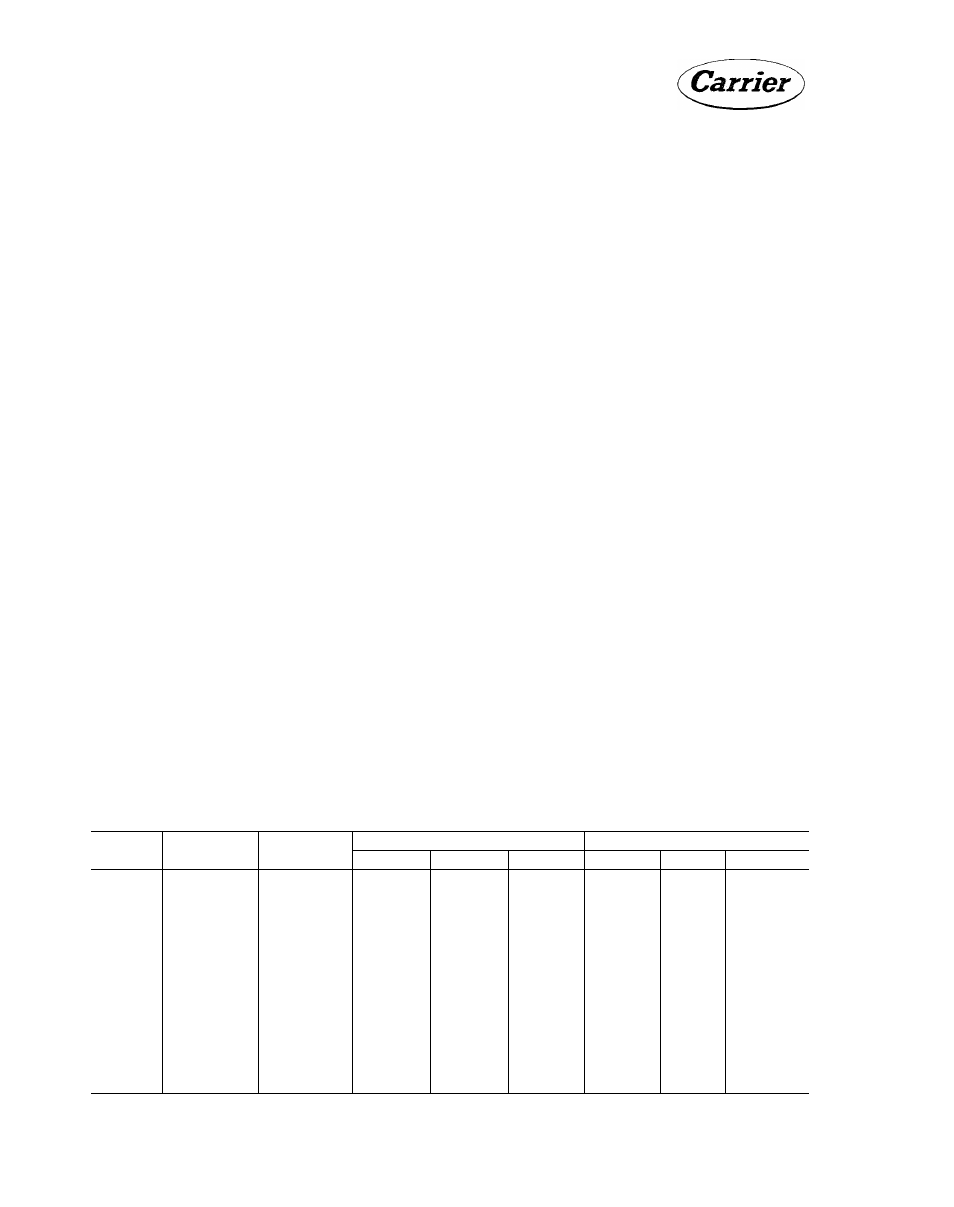

Table 1 - Weight and Overall Dimensions - 30HH.HJ Liquid Chiller Package

Unit

Shipping

Wt. (lbs.)

Operating

Wt. (lbs.)

Uncrated Dimensions (Ins.)

Crated Dimensions (Ins.)

Length

Width

Height

Length

Width

Height

30HH015

1430

1625

72

22-1/2

54-3/4

76

30

63

30HH020

2200

2150

72

22-1/2

54-3/4

76

30

63

30HJ015

1270

1460

72

22-1/2

47

76

30

63

ЗОН] 020

1700

1800

72

25-1/2

47

76

30

63

30HH025

2200

1950

72

22-1/2

54-3/4

76

30

63

30HH030

2550

1950

72

22-1/2

54-3/4

76

30

63

30H]025

2100

1800

72

25-1/2

47

76

30

63

30HJ030

2150

1850

72

25-1/2

47

76

30

63

30HH045

3010

3391

79-1/4

29-1/4

79

83-1/2

33

84-7/8

30HJ045

2455

2835

•79-1/4

29-1/4

66

83-1/2

33

84-7/8

30HH055

4622

5158

105-1/4

29-1/4

80-3/8

109-3/4

33

86-3/4

30HH065

4700

5236

105-1/4

29-1/4

80-3/8

109-3/4

33

86-3/4

30HJ065

3700

4236

105-1/4

29-1/4

У6

109-3/4

33

86-3/4