Electrical data, Capacity controls, 30hh,hj – Carrier 30HH User Manual

Page 40: Carrier, Installation

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

30HH,HJ

INSTALLATION

Carrier

ELECTRICAL DATA

The

6D73

and

6D75

compressors

(30HH,HJ

-

015,025,030 models) for 220 volt, 50 cycle ap

plication are supplied with six lead, part wind

ing

motors

and

extra

starters

to

provide

part

winding

start.

This

is

available

for

the

same

60 cycle units on special order.

Time delay relays are required for part winding

starting.

Staggered

starting

of

multiple

compressors

is

insured

by

the

step

controller

camshaft

drive

motor

and

recycle

relay.

Time

delay

relays

are not required.

Volts - 3 Phase

60 Cycle

Normal Network

Voltage

Application

Range

Voltage

Limits for

Satisfactory

Operation

208

208

187 to 229

230

220 to 240

198 to 264

460

440 to 480

396 to 528

575

550 to 600

495 to 660

CAPACITY CONTROLS

The

30HH,HJ

units

are

supplied

with

capacity

controls which cycle compressors and load and

unload

cylinders

of

one

compressor

to

give

capacity control steps shown in Table 12 below.

The

capacity

controls

supplied

with

each

unit

consists of a step controller, a solenoid-operated

cylinder

unloading

device

(two

unloaders

on

30HH015 and 30HJ015 units) and a chilled water

temperature controller.

Step Controller - The step controller includes

a small, low voltage motor with clockwise and

counter-clockwise

rotation

windings

that

drive

a

camshaft.

The

factory-set

cams

operate

load

switches

which

start

or

stop

compressors

and

load

or

unload

cylinders.

The

motor

windings

of the camshaft drive motor are energized by

a

balancing

relay

which

contains

windings

in

the

temperature

bridge

circuit

between

the

chilled

water

temperature

controller

and

the

motor

balancing

potentiometer

located

at

the

end of the camshaft. When the unit is loading

or

unloading

(counter-clockwise

or

clockwise

rotation of the camshaft drive motor), one chilled

water

temperature

corresponds

to

one

position

of the camshaft. Camshaft rotation is limited in

each direction by limit switches.

The step controller also includes a recycle re

lay which insures that the camshaft is fully re

cycled to the unload position at startup or after

a

power

interruption.

After

the

camshaft

has

recycled to the unload position, the chilled water

temperature

controller

takes

control

and

starts

camshaft

rotation

in

the

load

direction

which

starts

the

compressors

in

sequence,

insuring

staggered compressor starting in every case.

W'hile the unit is operating, the factory cam set

tings on the step controller protect the compres

sors against rapid cycling.

A

small

transformer

is

provided

in

the

step

controller which supplies 24 volt power to the

camshaft drive motor.

Cylinder Unloading Device - On the 30HH,HJ020

thru 30HH,HJ065 units a single cylinder unload

ing device is installed on the lead compressor.

The lead compressor is the farthest to the left

when

facing the

front

of the package, except

30HH,HJ045 units, where the lead compressor

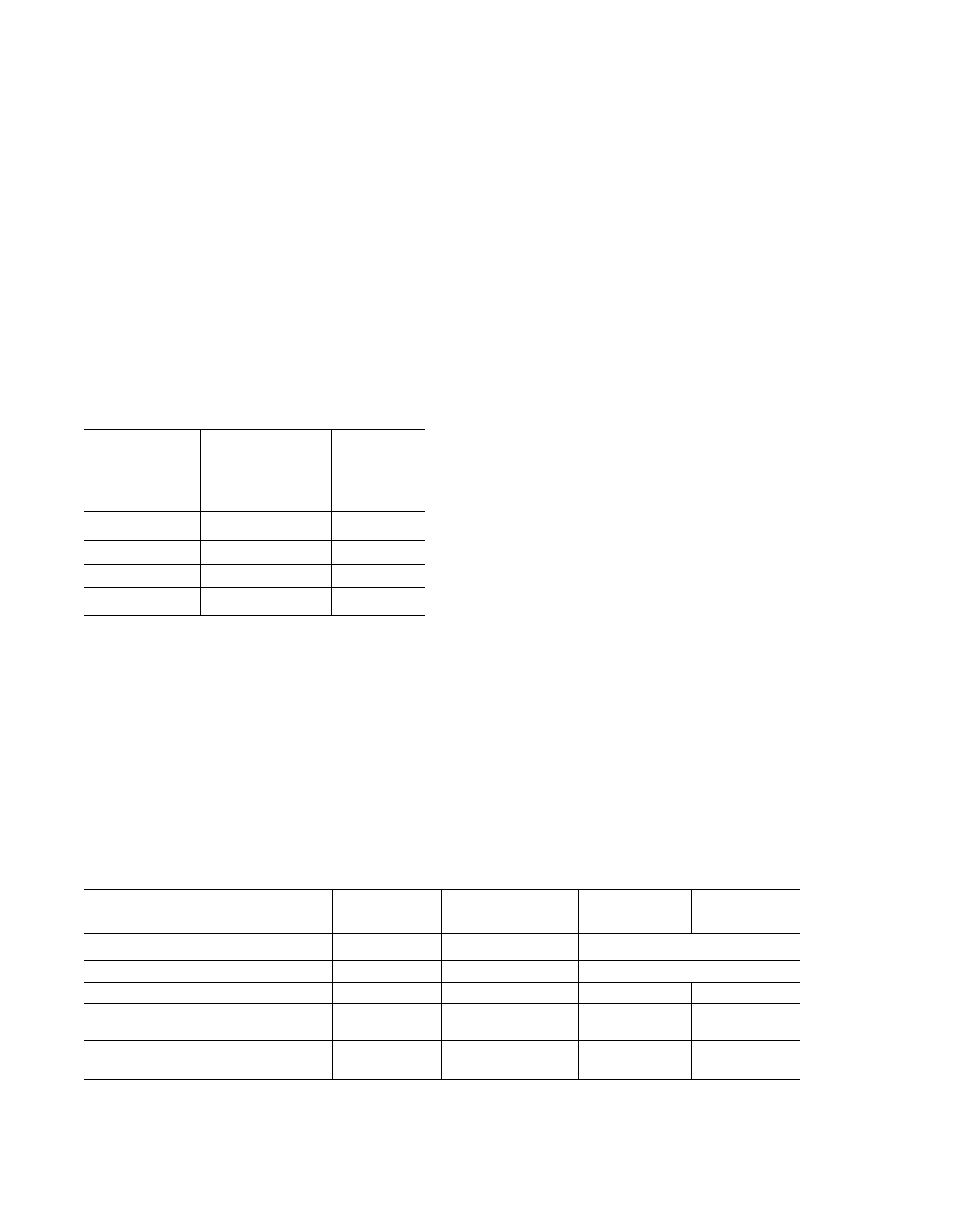

Table 12 - Capacity Control Steps

Model Size

30HH,HJ

015

30HH,HJ

020, 025, 030

30HH,HJ

045

30HH055

30HH,HJ065

Compressors

1

2

3

4

Cylinder Unloading Devices

2

1

1

1

Capacity Control Steps

3

4

6

7

Active Cylinders Per Step

2, 4, 6

4, 6, 10, 12

4, 6, 10, 12,

16, 18

4, 6, 10, 12,

16, 18, 24

Approx. Percent Load Per Step

33, 67, 100

33, 50, 83, 100

22, 33, 55, 67,

89, 100

17, 25, 42, 50

67, 75, 100

34