Procedure for dehydrating the system, Start-up procedures initial check, Installation – Carrier 30HH User Manual

Page 18

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

INSTALLATION

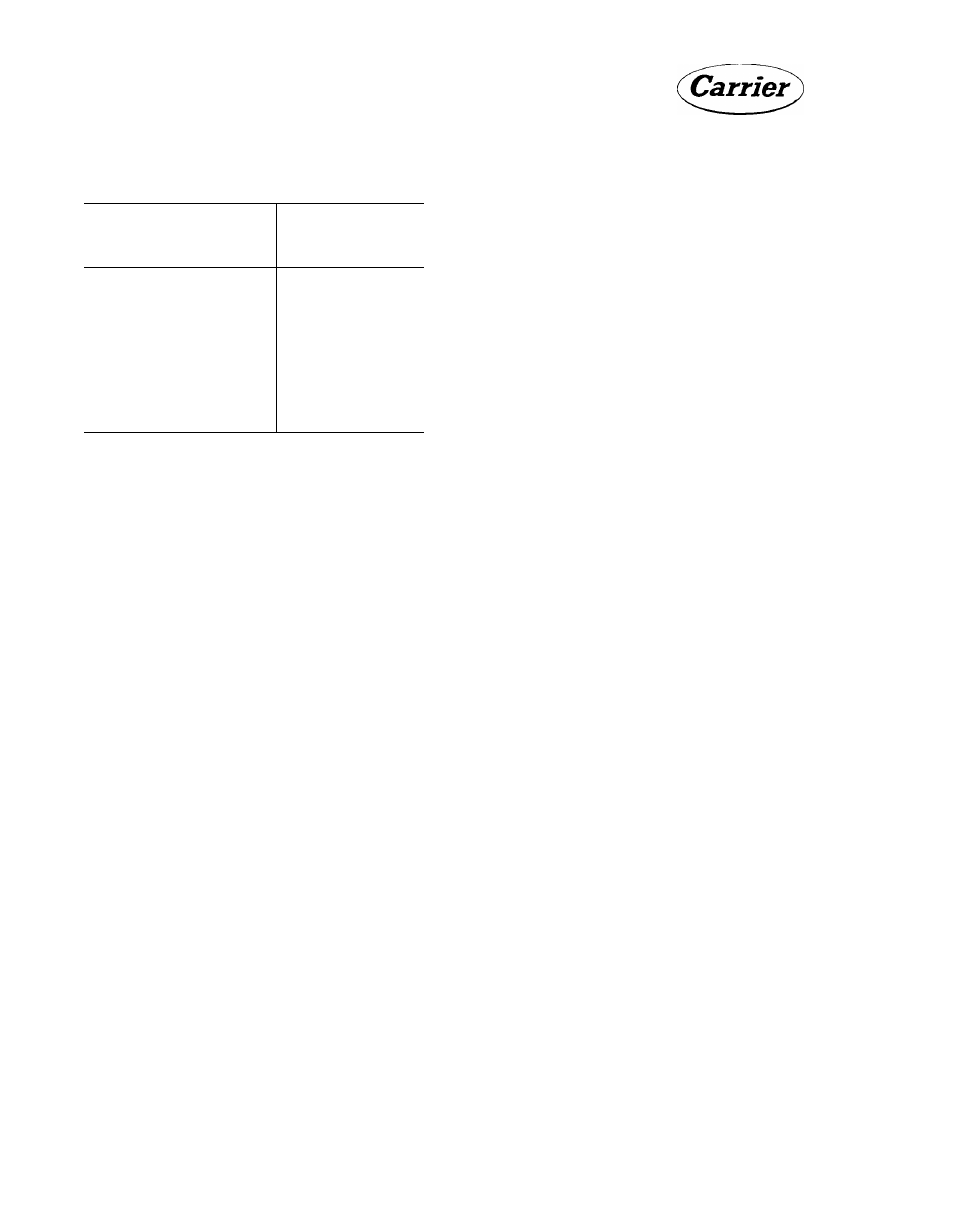

Table 7 - Vapor Pressures of Water

Temperature, degrees F

Observed on Vacuum

indicator

Absolute

Pressure

Inches of Mercury

70

0.739

60

0.522

55

0.436

50

0.363

45

0.300

40

0.248

35

0.204

32

0.180

NOTE:

To determine the vacuum in inches of

mercury

subtract

the

absolute

pressure

from the barometer reading.

seal of the indicator is not designed to support

a long run of connecting tubes. Fasten the tubes

to supports to prevent damage.

Use

only

distilled

water

in

the

indicator.

Be

sure the wick is clean. Oil or dirt on the wick

causes

erroneous

readings.

To

prevent

loss

of

oil

from

the

vacuum

pump

and

contamination

of the indicator;

1.

install a shut-off valve in the suction line at

the vacuum pump.

2.

Install a shut-off valve in the suction line at

the vacuum indicator.

3.

When shutting off the pump, close the indi

cator valve, the pump valve and turn off the

pump in that sequence.

Procedure for Dehydrating the System

1.

Connect the pump and vacuum indicator to

the system. Put a ’’jumper" line between the

high and low side so that the pump will draw

a vacuum on all portions of the system. Open

the

compressor

shut-off

valves.

Start

the

pump.

2.

Open the indicator connection shut-off valve

occasionally

and

take

a

reading.

Keep

the

valve open at least three minutes for each

reading. (Keep the valve closed at all other

times to decrease the amount of water the

pump

must

handle

and

hasten

dehydration.)

When the pressure in the system drops to a

value corresponding to the vapor pressure of

the

water

in

the

indicator,

the

temperature

will start to drop. In the example shown in

Fig.

25,

the

ambient

temperature

and

the

temperature of the water in the indicator is

60 F. Starting at 60 F and 0 time the temper

ature of the water in the indicator remains

at 60 F until the pressure in the system is

pulled down to the pressure corresponding to

the saturation temperature of the water (60 F).

At this point the moisture in the system will

start

to

boil.

The

temperature

drops

slowly

until the free moisture is removed (35 F).

Dehydration is nearly completed at this point

provided

the

ambient

temperature

remains

at 60 F or higher. If the ambient temperature

were lower than 60 F ice might form before

moisture removal is complete.

3.

Continue the dehydrating operation until the

vacuum indicator shows a reading of 35 F

which

corresponds

to

a

pressure

of

0.204”

Hg absolute. This may take several hours. It

may be advantageous to run the pump all

night.

4.

With the pump still running, open the system

at a point furthest from the pump and admit

air thru the drier. Close system and repeat

steps 2 and 3. Vapor left in the system is

thus

greatly

diluted

and

almost

completely

removed by double dehydration.

5.

After evacuation, turn off the pump suction

valve

and

break

the

vacuum

by

admitting

refrigerant.

START-UP PROCEDURES

initial Check

Do not attempt to start the ЗОНЫ and HJ Liquid

Chiller

even

momentarily

until

the

following

steps have been completed.

1.

Check all auxiliary components of the instal

lation

such

as

chilled

liquid

circulating

pump, cooling tower if used, air handling

equipment, or other equipment to which the

chiller supplies liquid. Consult the manufac

turer's instructions.

2.

Check safety thermostat. See "Safety Ther

mostat

Adjustment"

under

"CHECKING

THE CONTROLS."

3.

Backseat (open) the compressor suction and

discharge shut-off valves. Close the valves

18