Drain connection, Cooler water piping, 30hh,hj – Carrier 30HH User Manual

Page 14: Installation

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

30HH,HJ

INSTALLATION

Drain Connection

Drain

connections

are

generally

governed

by

local

codes.

Water

leaving

the

condenser

is

under

pressure

and

should

not

be

connected

directly

into

sewer

lines;

otherwise

water

may

back up into other fixtures. Local codes nor

mally

require

connections

similar

to

the

one

shown in Fig. 17.

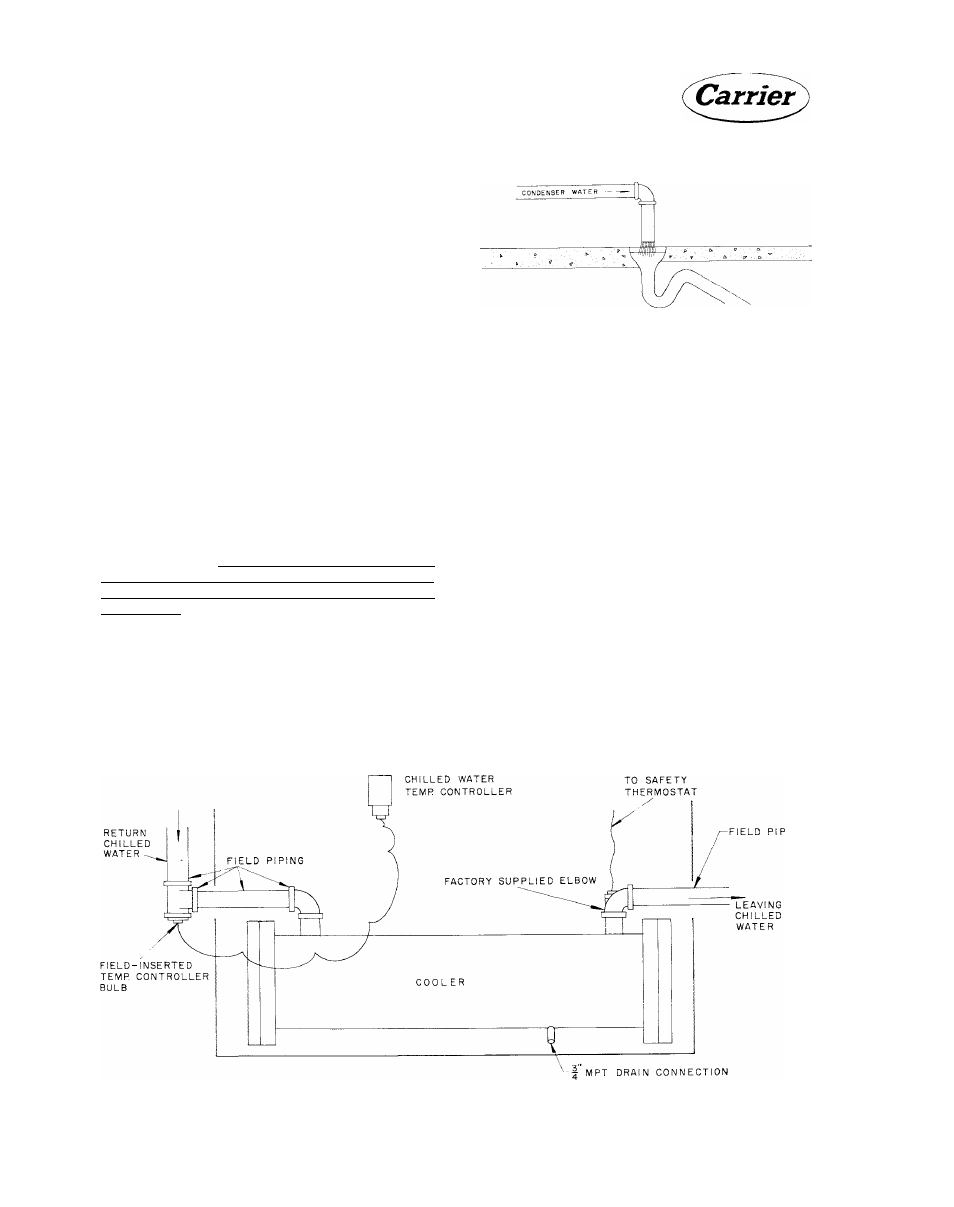

COOLER WATER PIPING

The cooler of each liquid chilling package is pro

vided with stubouts for chilled water piping con

nections.

The

water

outlet

stubout

is

provided

with a 90 degree elbow which contains the chilled

water

safety

thermostat

bulb.

Holes

are

pro

vided in both of the side panels for piping to the

stubouts.

The

chilled

water

temperature

controller

is

mounted on the front of the unit and has the con

trol bulb and capillary tubing wrapped and taped

before shipping. It is required that the control

bulb be field inserted in the chilled water line.

It usually is inserted in the return or inlet chilled

water piping. Figure 18 shows a typical chilled

water piping arrangement in the vicinity of the

cooler.

Details

of

the

required

remote

chilled

water piping are outlined in the Carrier System

Design Manual, Part 3, "Piping Design."

Plan the piping so it has a minimum number of

changes

in

elevation.

A

manual

or

automatic

Fig. 17 - Drain Connections

vent-valve must be installed at the high points

in the line to permit venting of air from the

chilled

water

circuit.

Standard

practice

for

in

stalling forced water systems must be followed.

System pressures may be maintained by using a

pressure tank or a combination relief valve and

reducing valve.

It

is

recommended

that

thermometers

be

in

stalled

in

entering

and

leaving

chilled

liquid

lines. Provide drain connections at all low points

to permit complete drainage of the system. A

chiller drain shut-off valve should be connected

to the chiller drain line before placing the unit

in operation (Fig. 18).

Insulate piping to prevent heat loss and sweating.

Cover the insulation with a moisture seal. Do

not insulate piping before all leak testing has

been completed.

Fig. 18 - Cooler Water Piping, Front View

14