Condenser maintenance, Effect of condenser on head pressure, How to purge noncondensable gases – Carrier 30HH User Manual

Page 44: Inspecting shell and tube condensers, Cleaning shell and tube condensers, Cleaning shell and coil condenser, The gravity flow method of cleaning, 30hh,hj, Carrier, Maintenance

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

30HH,HJ

MAINTENANCE

Carrier

Ü I

CONDENSER MAINTENANCE

Effect of Condenser on Head Pressure

The normal head pressure for an installation is

determined when the job is engineered. Too great

a variation from normal may be caused by:

1.

Incorrect adjustment of the water regulating

valve. (See Water Regulating Valve - Check

Controls.)

2. Noncond'ensable gases.

3. incorrect refrigerant charge.

4. Scaled condenser tubes.

How to Purge Noncondensable Gases

Purge noncondensable gases thru the purge cock

on top of the condenser or receiver.

TUBE SHEET

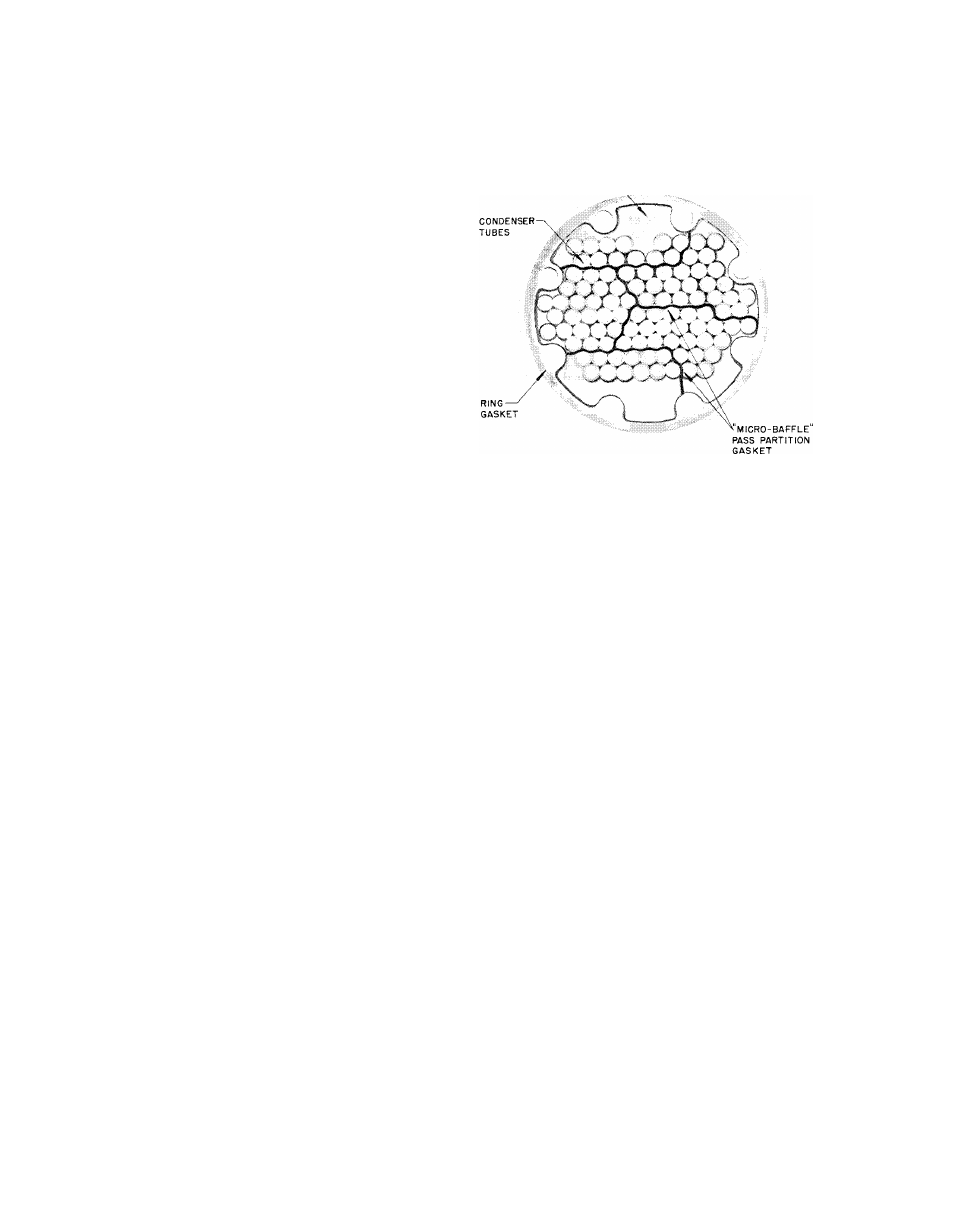

Fig. 43 - Location of Pass Partition (Typical

Inspecting Shell and Tube Condensers

The shell and tube condensers used on 30HH055,

065 chillers can be inspected on the water side

by removing the heads. It is not necessary to

pump down. The necessary steps are as follows;

1. Shut off the machine.

2.

Shut off condenser water supply and discon

nect the inlet and outlet piping.

3.

Backseat

the

angle

valve

connecting

the

water regulating valve capillary to the con

denser

and

disconnect

the

tubing

from

the

valve.

4.

Remove tne drain plugs from the bottoms of

the heads and the vent plug from the top of

the front head and drain the water.

5. Remove the head bolts and heads.

A "Micro-Baffle" pass partition gasket made of

soft

metal

seals

the

water

passes

(Fig.

43).

When replacing a damaged gasket be sure to get

a new one in the correct position.

Cleaning Shell and Tube Condensers

To clean the tubes on 30HH055,065 chillers, use

a

special

nylon

brush

(available

from

local

Carrier

Distributor)

or

a

similar

brush

at

tached to a rod. If hard scale has formed, the

coils should be cleaned chemically. Do not use

brushes that will scrape and scratch the tube's.

Experience has shown that once the tubing has

been scratched, corrosion takes place which re

sults in pitting of the tubes. This is less likely

to occur with chemical cleaning.

Flush water thru the coils while brushing. The

results are best if the brush is turned with a

slow speed electric drill.

It is also possible to clean the tubes by using air

pressure to force rubber plugs thru the tubing.

After the tubes are cleaned, install the heads,

connect the water lines, and flush the condenser

to remove any remaining sediment.

Cleaning Shell and Coil Condenser

The simplest method of cleaning shell and coil

condensers is with inhibited acid. Use an inhib

ited

hydrochloric

acid

solution such

as

"Oakite

32." Handle the acid with the usual precautions

because it will stain the hands and clothing and

attack concrete. If the inhibitor is not present^

it will attack steel. Where splashing may occur,

cover the surfaces with burlap or boards. Gas

coming from the vent pipe during cleaning is not

harmful,

but

take

care

to

prevent liquid

from

being carrier over by the gas. The solution acts

more readily if it is warm, but a cold solution

and a longer time does just as thorough a job.

The Gravity Flow Method of Cleaning

The gravity flow method of cleaning is shown in

Fig. 44. Do not add the solution more rapidly

38