Compressor mounting, 30hh,hj, Carrier – Carrier 30HH User Manual

Page 10: Installation

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

30HH,HJ

INSTALLATION

Carrier

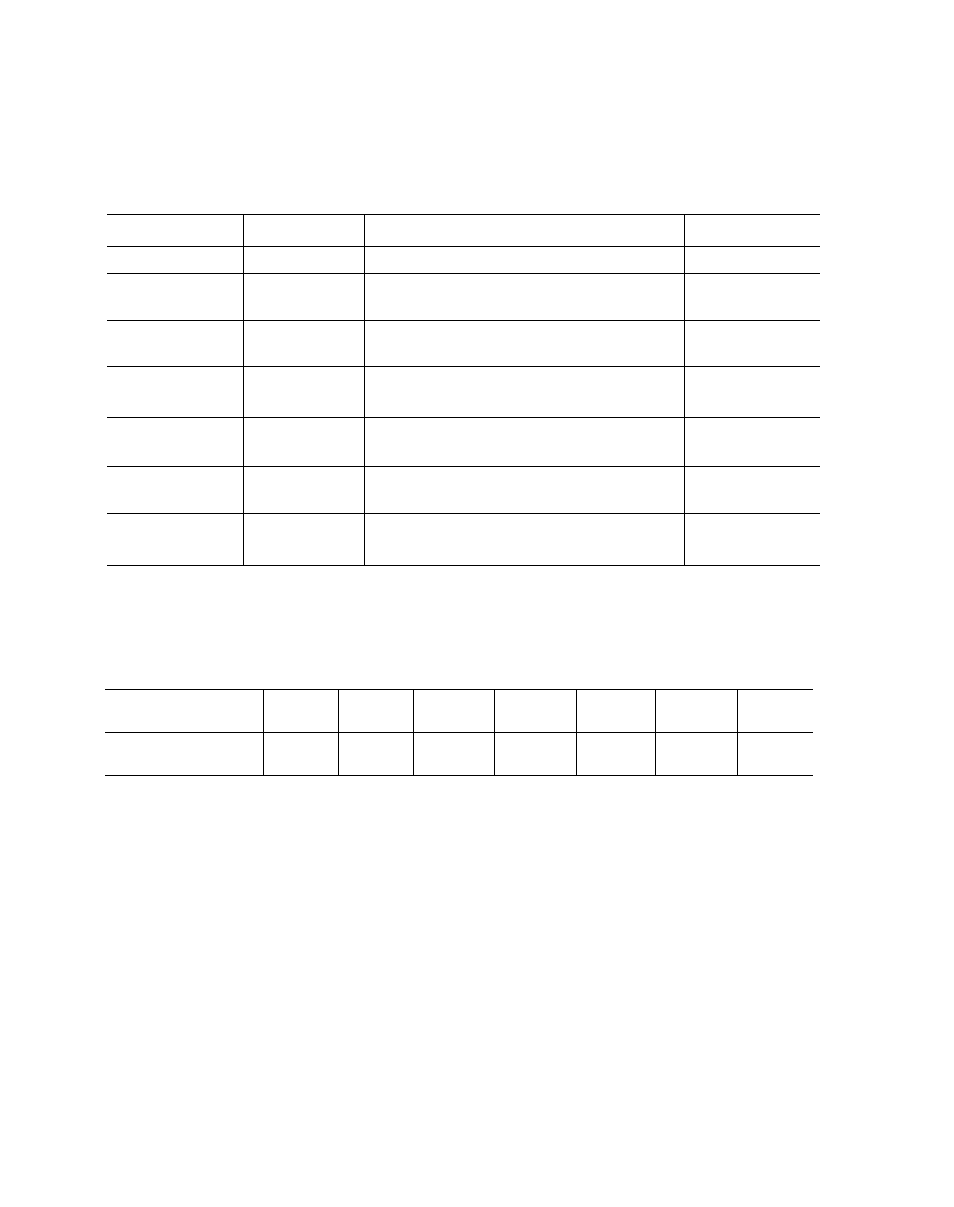

Table 5 - Refrigerant Circuits

Unit Size

Circuits

Description of Refrigerant Circuit

Capacity (%)

зоны, HJ015

1

(i) 6D73 or 6D75 Compr, Full Cooler Surface

100

(1) 6D68 Compr, 1/2 Cooler Surface

50

30HH, HJ020

2

(1) 6D68 Compr, 1/2 Cooler Surface

50

(1) 6D68 Compr, 1/2 Cooler Surface

40

зоны, HJ025

2

(1) 6D73 or 6D75 Compr, 1/2 Cooler Surface

60

(1) 6D73 or 6D75 Compr, 1/2 Cooler Surface

50

ЗОНЫ, HJ030

2

(1) 6D73 or 6D75 Compr, 1/2 Cooler Surface

50

(1) 6D73 or 6D75 Compr, 1/3 Cooler Surface

33

ЗОНН, HJ045

2

(2) 6D73 or 6D7S Compr, 2/3 Cooler Surface

67

(2) 6D73 Compr, 1/2 Cooler Surface

55

30НН055

2

(1) 6D73 & (1) 6D68 Compr, 1/2 Cooler Surface

45

(2) 6D73 or 6D75 Compr, 1/2 Cooler Surface

50

ЗОНН, HJ065

2

(2) 6D73 or 6D75 Comipr, 1/2 Cooler Surface

50

NOTE: 6D73 Compressors arc used on ЗОНЫ models. 6D75 Compressors are used on 30HJ miodels.

Table 6 - Refrigerant Charge

Model ЗОНН, HJ

015

020

025

030

045

055

065

Refrigerant 22 (lb)

35

46

46

46

69

124

140

NOTES: 1. The refrigerant charges listed above do

not include the additional charge required

for remote condensers and piping with

ЗОН] models.

2. The 30HH015 and 30HH020 units are

shipped fully charged with refrigerant.

Other units are shipped with holding

charges only.

COMPRESSOR MOUNTING

All 30HH,HJ chillers, as shipped, have the com

pressor rigidly mounted to the frame with bolts

and

steel

pipe

spacers.

For

proper

operation,

the following procedure should be followed;

30HH,HJ020 to 030 units (Fig. 8):

1. Loosen the four (4) hold-down bolts on one

compressor.

2. Remove one hold-down bolt, lock washer

and nut on oil pump end of compressor. Lift

end of compressor and remove pipe spacer.

3.

Tighten hold-down bolt which is diagonally

opposite spacer which was removed.

4.

Install 3/8-16 X 1-1/2" bolt, supplied in bag

of

fastenings,

between

compressor

foot

and

bracket. Reinstall lock washer and nut.

5. Loosen hold-down bolt tightened in step No. 3.

6.

Repeat steps 2 thru 5 for other oil pump end

bolt.

10