Installation, Water regulating valve, Temperature controller adjustment – Carrier 30HH User Manual

Page 24: 30hh,hj, Carrier

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

30HH,HJ

INSTALLATION

Carrier

Two eight ampere fuses protect the control cir

cuit against overload. The control light will be

on

whenever

the

control

circuit

is

energized.

Disengage the fuse caps to remove blown fuses.

The "X" values (Table 10) were established by

experimentation and are such that the compres

sor is prevented from cycling more than once

in a five minute period.

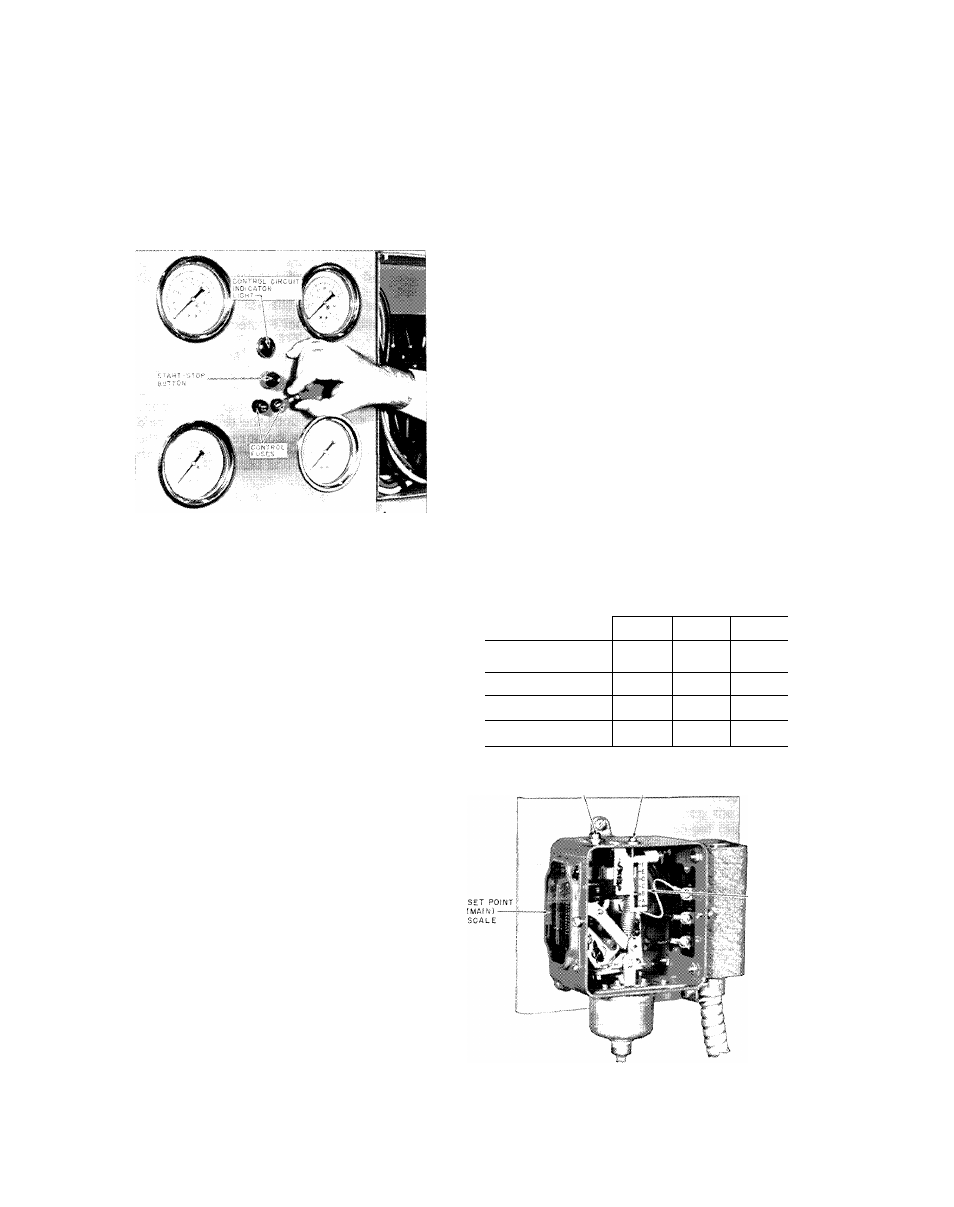

Fig. 28 - Gauge Panel (30HH,HJ045)

The throttling range is determined as follows;

Throttling Range (modulating) =

Design Rise + "X”

The

throttling

range

setting

is

arrived

at

by

entering the graph below at the "set point” and

moving across an amount equal to the throttling

range. The setting is read from the top scale

and will fall somewhere between min. - F. To

illustrate, with a 30HH065 Chiller, a 4-compres

sor unit, at a 10 F design rise, 45 F leaving

chilled

water

temperature,

the

set

point

would

be 45 - 1 = 44 F. The throttling range would be

10 + 1 = F.

Entering the graph at 44 F and moving across

11

F indicates a throttling range setting of just

under "A”.

Table 10 - ”X” Values, F

WATER REGULATING VALVE

The

water

regulating

valve

should

be

set

to

maintain the most economical head pressure as

determined by the design engineer, based on the

relative cost of water and electricity in a given

area. It should not be adjusted to compensate

for high head pressures caused by fouled con

denser

tubes,

excess

refrigerant

or

the

pres

ence

of

noncondensables.

Due

to

changes

in

water

temperatures,

it

may

be

necessary

to

adjust

the

valve

seasonally.

After

adjusting

for

the

economical

head

pressure,

the

machine

should be shut down. The water regulating valve

should shut off the flow of water in a few min

utes. If it does not, it will be necessary to

raise the head pressure setting. The water reg

ulating

valve

is

used

for

city

water

and

in

some

cases

with

multiple

units

on

a

single

cooling tower.

TEMPERATURE CONTROLLER ADJUSTMENT

The

chilled

water

temperature

controller

must

be

adjusted

in the field before initial startup.

Two adjustments are required - Set Point (main

scale, 15 - 90 F) and Throttling Range (modu

lating, min - F).

The set point is determined as follows ;

Set Point = Design Leaving Chilled Water

Temperature - ”X”

Design Rise F

No. of Comp.

8

10

12

1

2.0

2.5

3.0

2

2.0

2.5

3.0

3

1.25

1.5

1.75

4

.75

1.0

1.25

S E T P O I N T

A D J U S T M E N T S C R E W

T H R O T T L I N G R A N G E ( M O D U L A T I N G )

^ A D J U S T M E N T S C R E W

T H R O T T L I N G

R A N G E

S C A L E

Fig. 29 - Chilled Water Temperature

Controller

24