30hh,hj, Installation – Carrier 30HH User Manual

Page 16

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

30HH,HJ

INSTALLATION

In order to prevent condensed liquid refrigerant

or oil from causing damage to the compressor,

install a trap in the vertical discharge line near

the compressor. The trap may be installed within

or adjacent to the unit base. The height of the

trap (or loop) should be 6 inches for every 10

feet of vertical discharge line. If the height of

the vertical discharge line is such as to make

a single trap impractical, the loop can be re

placed by a check valve or several traps.

To prevent the formation of copper oxide when

brazing copper tubing, bleed a small amount of

dry nitrogen gas thru the piping. The nitrogen

will displace the air containing oxygen.

Complete

all

field

piping

before

removing

the

seals on the unit refrigerant piping. Upon com

pletion of the field piping, add a small amount

of

refrigerant

and

build

up

the

required

test

pressure with dry nitrogen or other inert gas.

If

a

test

pressure

is

not

specified,

ASA-B9

Code calls for 300 psig high side and 150 psig

low side test pressures for R 22.

NOTE: 1. Install mufflers as close to compres

sor discharge valve as possible.

2.

Make sure a pressure relief device is

installed in the hot gas line or con

denser used with the 30HJ models.

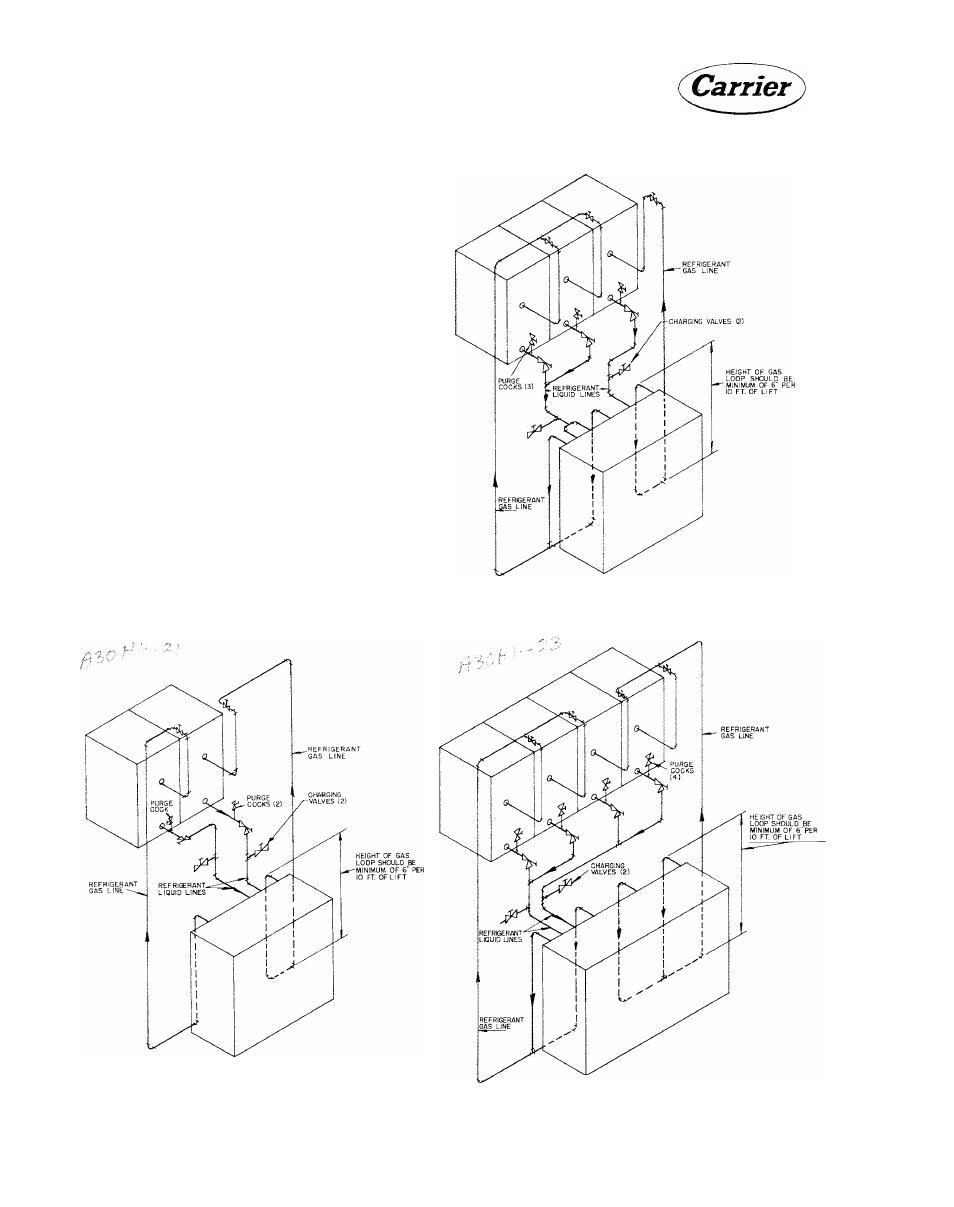

Fig. 21 - Rafrigerant Piping to Three Air-

Cooled Condensers 30HJ045 (without Receivers)

Fig. 20 - Refrigerant Piping to Two Air-

Cooled Condensers 30HJ020,025,030

(without Receivers)

Fig. 22 - Refrigerant Piping to Four Air-

Cooled Condensers 30HJ065 (without Receivers)

16