Top Flite TOPA0700 User Manual

Page 9

wr

inkles

.

T

he best w

a

y is to glide the iron o

ver the

co

ve

ring until the wr

inkles disappear

, then go o

ver the

area again, pushing do

wn on the iron to bond the

co

ve

ring to the w

ood.

If the wr

inkles don’t go a

w

a

y, the

balsa in that area ma

y be bending inw

ard.

If this is

happening, don’t press do

wn.

Simply let the heat of the

iron shr

ink the co

ve

ring.

If the wr

inkles momentar

ily

disappear

, then immediately reappear

, the iron ma

y be

too hot, thus causing air b

u

b

b

les

.

L

o

w

er the

temper

ature of the iron or use a shar

p #11 b

lade to

puncture se

ve

ral holes in the co

ve

ring, then reheat.

The

suggested iron temper

ature is around 360 deg

rees F

.

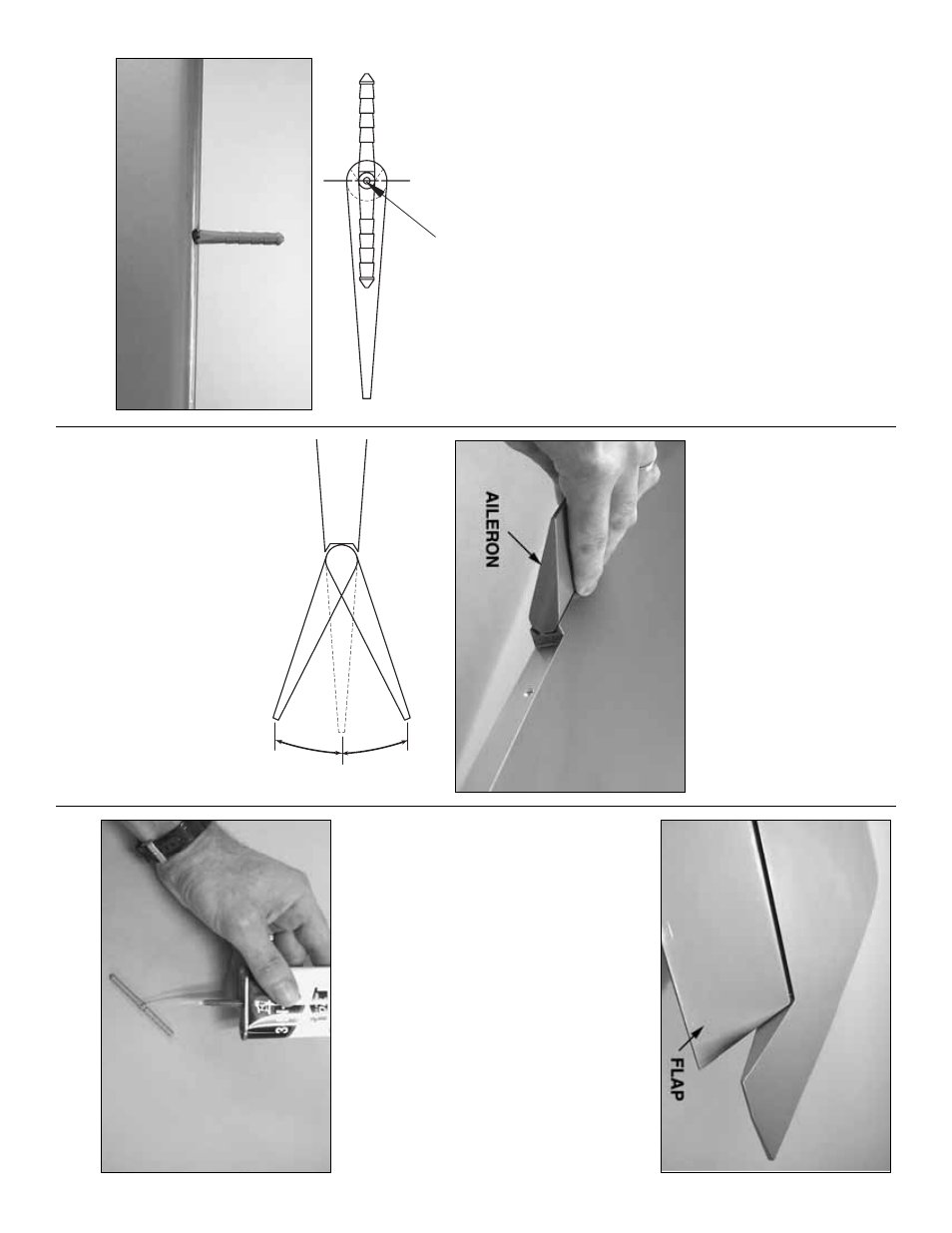

❏❏

4.

Cut the co

v

e

ring from the holes f

or the hinge

points in the tr

ailing edge of the wing and the leading

edge of the flap and aileron.

There are three holes f

o

r

the aileron and f

our holes f

or the flap

.

N

ote that the

holes in the flap and aileron are elongated.

❏❏

5.

Shor

ten one of the pinned hinge points b

y

cutting the last segment off one end.

This hinge will

be f

or the outer

most hole in the aileron.

❏❏

6.

Without using an

y glue

, install three hinges into

the aileron.

The one shor

tened in the pre

vious step

goes in the hole nearest the outer tip

.

Note that the

piv

ot point

of each hinge m

ust align with the

center

of

the r

adius on the leading edge

.

T

o achie

v

e

this

alignment the hinges will be f

air

ly deep in the aileron.

Also note that the hinges m

ust be per

pendicular to the

leading edge

.

If necessar

y, use an electr

ic dr

ill to r

un a

3/16" [4.8mm] dr

ill bit into the holes to achie

ve

this

alignment.

Be careful not to dr

ill through the sheeting

o

ver the top and bottom of the aileron.

❏❏

7.

Again without glue

, test fit the aileron to the

wing.

Mo

ve

it up and do

wn a f

e

w times to align the

hinges—it doesn’t ha

ve

to mo

ve

v

e

ry

f

ar—only 3/4"

[19mm] up and 3/4" [19mm] do

wn (measured at the

widest par

t of the aileron at the tr

ailing edge as sho

wn

in the photo).

If there is too m

uch resistance

, or if y

o

u

are not ab

le to mo

ve

the aileron up and do

wn 3/4"

[19mm], widen the gap betw

een the aileron and the

wing b

y

pulling the aileron from the wing slightly

, or

enlarge the hinge openings in the aileron.

❏❏

8.

Still using no glue

, test fit the flap to the wing

the same w

a

y.

2-1/8" [55mm] of do

wn deflection is

required (measured at the widest par

t of the flap).

W

e

’ll glue on the flap and ailer

on separatel

y

.This

wa

y y

ou will ha

ve plenty of w

orking time f

or

the epo

xy

.

❏❏

9.

Remo

v

e

all the hinges

.

Add a

small

drop of

oil to the piv

ot point on the aileron hinges

.

3/4"

3/4"

HINGE PIV

O

T

POINT

- 9

-