Top Flite TOPA0700 User Manual

Page 27

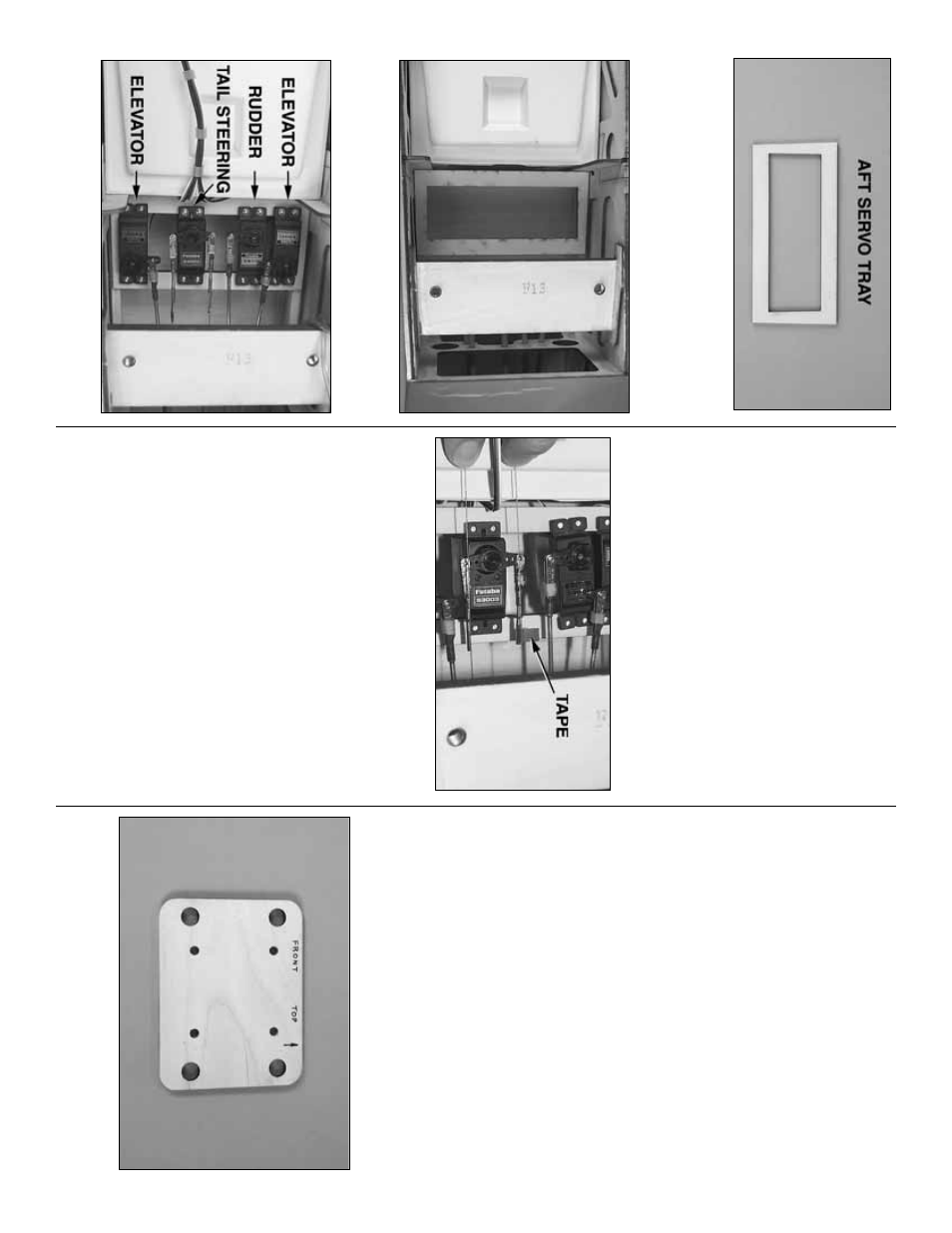

❏

4.

Glue together both 1/8" [3mm] plyw

ood

aft

ser

v

o

tra

ys

.T

est fit the tw

o ele

v

ator

, one r

udder and

one tail wheel ser

v

o

in the tr

a

y.

Mak

e an

y

adjustments required so the ser

v

o

s fit.

❏

5.

Place the ser

v

o

tr

a

y

in the fuselage

.

Ref

er to this photo while hooking up the ser

v

os.

❏

6.

Place all f

our ser

v

os in the ser

v

o

tr

a

y.

M

ak

e

three one-ar

m ser

v

o

ar

ms and one tw

o-ar

m ser

v

o

ar

m from the ar

ms that came with y

our ser

v

o

s

.

Place

the ar

ms on the ser

v

os as sho

wn in the photo

.

❏

7.

The same as w

as done f

or the aileron and flap

pushrods

, mar

k the ele

v

a

tor and r

udder pushrods

where the

y are to be cut f

or solder

ing on the cle

vises

.

One at a time

, unthread each pushrod from the cle

vis

on the control hor

n, remo

v

e

the pushrod from the

fuselage

, cut it to the correct length, then solder on

the cle

vis

.

Reinstall the pushrod from the front, then

connect them to the ser

v

o

ar

ms and control hor

ns

.

Don’t f

orget to use a silicone retainer on all the

cle

vises and to install 4-40 n

uts on the pushrods

ahead of the thread-on cle

vises

.

❏

8.

Connect the tw

o cle

vises with the threaded,

br

ass couplers and n

uts on them to both ends of the

tail steer

ing ser

v

o

ar

m.

Put a small piece of tape on

one of the pull/pull cab

les coming from the tail

steer

ing ar

m.

Center the tail wheel and slide the tape

along the cab

le to mar

k where it will be looped-o

v

e

r

to go into the br

ass coupler

.

❏

9.

T

a

k

e

the ser

v

o

ar

m off the tail steer

ing ser

v

o

and disconnect the cab

le from the ball link on the

steer

ing ar

m.

Pull the cab

le up through the guide

tube

.

Use the tape as a ref

erence f

or where to bend

the cab

le to loop it through the br

ass coupler

.

Secure

the cab

le to the coupler with a s

w

age

.

❏

10.

Guide the looped end of the cab

le bac

k do

wn

through the guide tube and reconnect it to the ball

link ball on the steer

ing ar

m.

Mar

k and connect the

other cab

le to the br

ass coupler on the other side of

the ser

v

o

ar

m same w

a

y.

❏

11.

Mar

k the hole locations f

o

r the ser

v

o mounting

scre

ws on the ser

v

o

tr

a

y.

R

emo

v

e the ser

v

o

tr

a

y, then

dr

ill 1/16" [1.6mm] holes at the mar

k

s

.

Scre

w

, then

remo

v

e

a scre

w in each hole

.

Add a f

e

w drops of thin

CA and allo

w to harden.

❏

12.

Securely glue the ser

v

o

tr

a

y

in the fuselage

with 30-min

ute epo

xy

.

M

ount the ser

v

os in the tr

a

y

and hookup the pushrods

.

We

’ll finish up the rest of the radio installation

and mount the components f

or the air system

after the engine has been mounted.

Mount the engine

The f

ollo

wing instr

uctions illustr

ate ho

w to mount a

U

.S

.

Engines 41cc gas engine

.

A

Great Planes

Gasoline Engine Mount (GPMG2000—not included)

and the par

ts included with this model will pro

vide

the correct alignment and spacing.

If not using a

U

.S

.

Engines 41cc engine

, use the appropr

iate

hardw

are to mount y

our engine (or engine mount)

centered on the hor

iz

ontal and v

e

rtical alignment

mar

ks on the fire

w

all.

Note that the bac

k of the

spinner bac

kplate should be 7-1/2" to 7-3/4" [190 to

200mm] from the fire

w

all.

❏

1.

If using a U

.S

.

Engines 41cc engine

, use the

engine mount template

in the bac

k of the man

ual to

mar

k the engine mounting bolt locations on a Great

- 27

-