Top Flite TOPA0700 User Manual

Page 12

❏❏

14.

Place the hatch co

v

ers with the ser

v

os in

the wing.

Be cer

tain the hatch co

v

ers are positioned

correctly as sho

wn in the photos bac

k at step 5.

Dr

ill

six 1/16" [1.6mm] e

v

enly spaced holes through the

hatch co

v

ers into the wing.

Enlarge the holes

in the

hatc

h co

ver

s onl

y

with a 3/32" [2.4mm] dr

ill.

❏❏

15.

Connect a 24" [610mm] ser

v

o

e

xtension

wire to the aileron ser

v

o

.

Cut one of the pieces of 3"

[75mm] heat shr

ink tubing supplied with this kit in

half

.

Slip the tubing o

v

er the connection betw

een the

ser

v

o

and the e

xtension wire

, then carefully shr

ink

the tubing b

y

heating with a heat gun.

❏❏

16.

Use the str

ing in the wing to pull the aileron

wire through the wing.

Mount the aileron hatch with

six #2 x 3/8" [9.5mm] scre

ws

.

❏❏

17.

Guide the flap ser

v

o

wire through the wing

alongside the aileron ser

v

o

wire

.

M

ount the flap

hatch with six more #2 x 3/8" [9.5mm] scre

ws

.

❏

18.

Mount the aileron and flap ser

v

os and hatches

in the r

ight wing the same w

a

y.

Hook up the ser

v

o

s

Do the left ailer

on fir

st.

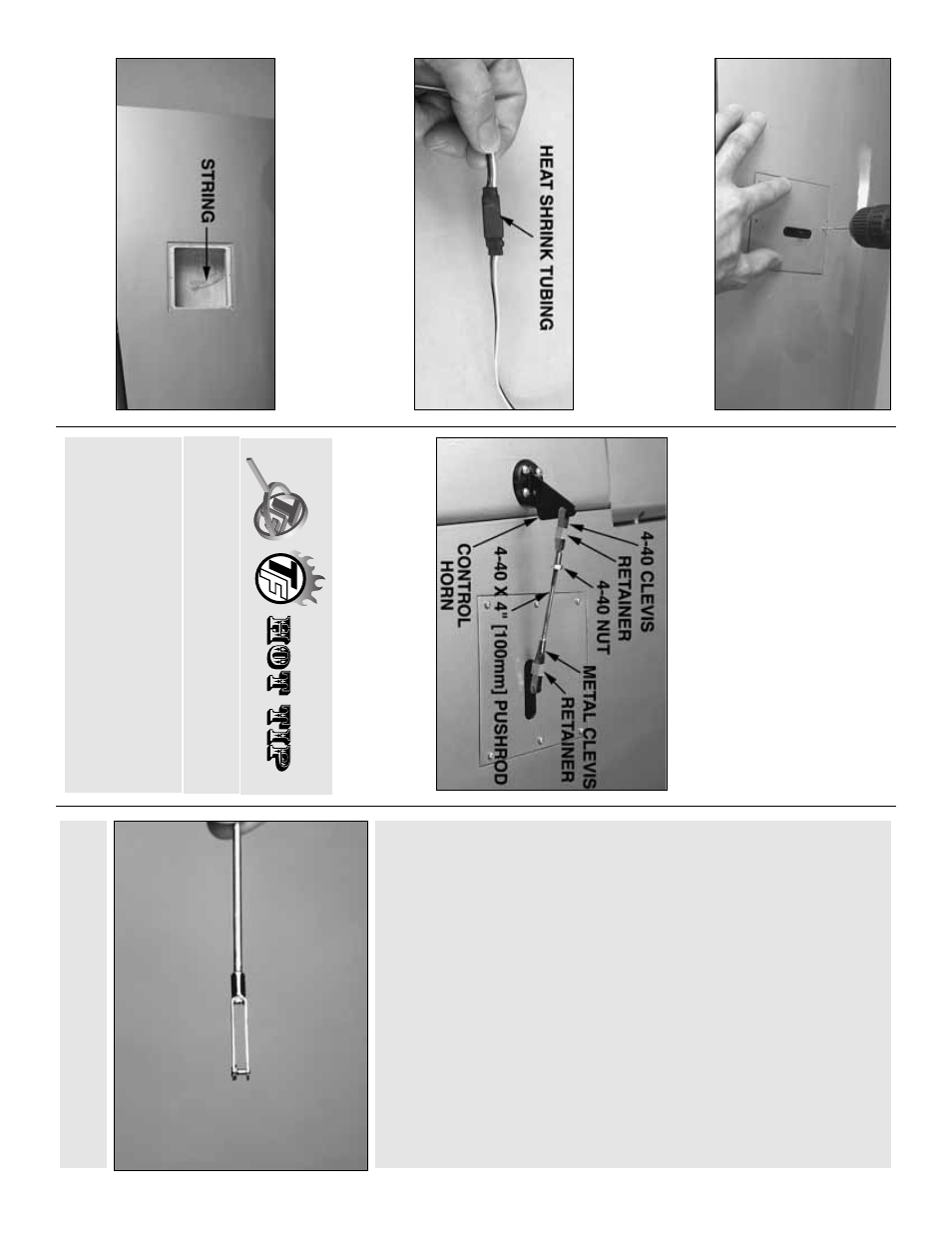

❏❏

1.

Ref

err

ing to the photo abo

v

e

, cut the

ailer

o

n

pushr

od

to the correct length, then solder it to a

large

, non-threaded metal cle

vis using the

techniques descr

ibed in the f

ollo

wing

Hot Tip

.

This is what a proper

ly soldered cle

vis looks lik

e—

shin

y solder with good flo

w

, no b

lobs

, flux remo

ved.

2.

Apply a f

e

w drops of solder

ing flux to the end

of the pushrod, then use a solder

ing iron or a

torch to heat it.

“Tin”

the heated area with

silver solder

(GPMR8070) b

y

applying the

solder to the end.

The heat of the pushrod

should melt the solder—not the flame of the

torch or solder

ing iron—thus allo

wing the

solder to flo

w

.

The end of the wire should be

coated with solder all the w

a

y around.

3.

Place the cle

vis on the end of the pushrod.

Add

another drop of flux, then heat and add solder

.

The same as bef

ore

, the heat of the par

ts

being soldered should melt the solder

, thus

allo

wing it to flo

w

.

Allo

w the joint to cool

natur

ally without disturbing.

A

v

oid e

xcess

b

lobs

, b

ut mak

e

cer

tain the joint is thoroughly

soldered.

The solder should be shin

y,

not

rough.

If necessar

y,

reheat the joint and allo

w

to cool.

4.

Immediately after the solder has solidified, b

u

t

while it is still hot, use a cloth to quic

kly wipe

off the flux bef

ore it hardens

.

Impor

tant:

After

the joint cools

, coat with oil to pre

v

ent r

ust.

Note:

Do not use the acid flux that comes with

silv

er solder f

o

r electr

ical solder

ing.

1.

Use denatured alcohol or other solv

ent to

thoroughly clean the pushrod.

Roughen the

end of the pushrod with coarse sandpaper

where it is to be soldered.

HO

W T

O

SOLDER

- 12

-