Top Flite TOPA0410 User Manual

Page 9

- 9 -

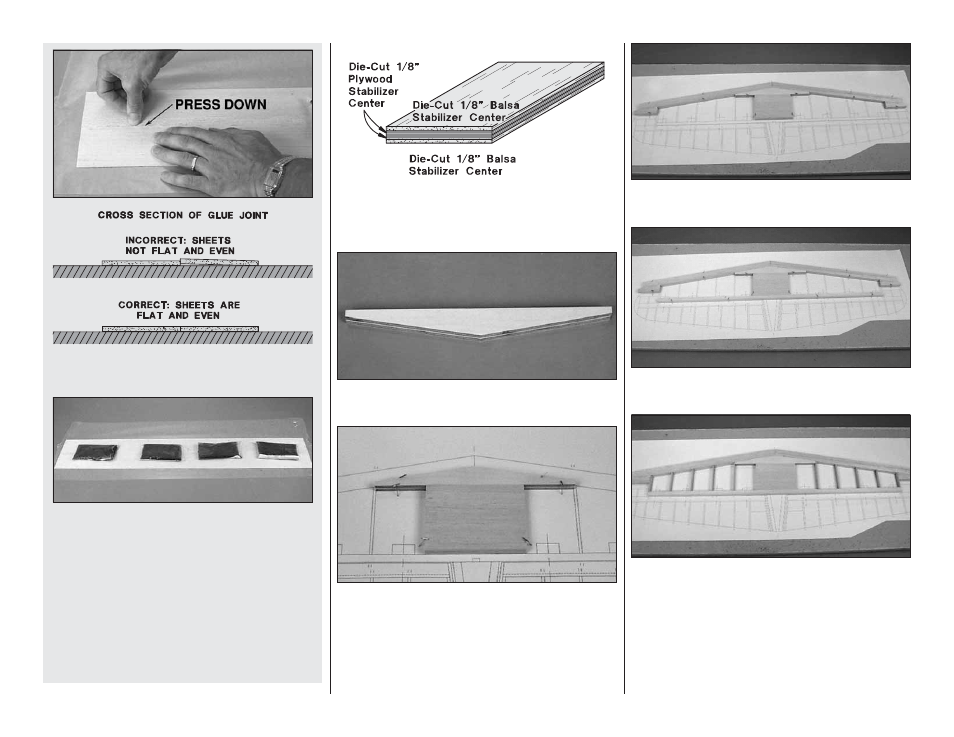

❏ E. Inspect the seam and press the sheets together

where they do not align.

❏ F. Place weights on top of the sheets to hold them

down. We prefer plastic bags filled with lead shot, but

anything similar will do the job.

❏ G. After the glue dries, remove the weights and

masking tape. Sand the sheet flat with your bar sander

and 150-grit sandpaper. The idea is to sand the

sheeting before you glue it to the structure. This

eliminates low spots that can occur over the ribs from

excessive sanding.

This is the same procedure we recommend when it is

time to make the wing and fuse skins.

❏ 2. Use 30-minute epoxy to glue the two die-cut 1/8"

[3.2mm] plywood stab centers (SC) between the two 1/8"

[3.2mm] balsa stab centers. To ensure that the lamination

stays flat, clamp it to a flat table until the epoxy cures.

❏ 3. Use epoxy to glue the two shaped 1/4" [6.4mm]

plywood leading edge doublers together.

❏ 4. Place the stab plan on a flat building board (you may

wish to cut out the stab section) and cover the stab plan

with plan protector or wax paper. Pin the ply LE doubler

over the plan and glue the stab center to its aft edge.

❏ 5. From the 1/2" x 7/8" x 24" balsa sticks, cut and

glue stab LE’s to the LE doubler. Pin the LE’s to the

building board.

❏ 6. From the remaining 1/2" x 7/8" balsa stick, cut and

glue the stab tips to the LE.

❏ 7. Cut the 3/8" x 1/2" x 30" balsa stab TE to length. Pin

and glue the TE in position at the aft edge of the stab center.

❏ 8. From the 1/8" x 1/2" x 30" balsa sticks, cut and glue

stab ribs between the LE and TE. Note: Sand a bevel on

the LE of the ribs to fit the angle of the stab LE.

❏ 9. Remove the stab from your building board. Inspect all

the glue joints and add CA to any joints that don’t appear

strong. Trim and sand the LE and stab tips to match the

shape on the stab plan. Use a bar sander to sand the

entire top and bottom surface until it is flat and even. Be

careful that you don’t sand any area of the stab too thin.