Top Flite TOPA0410 User Manual

Page 41

- 41 -

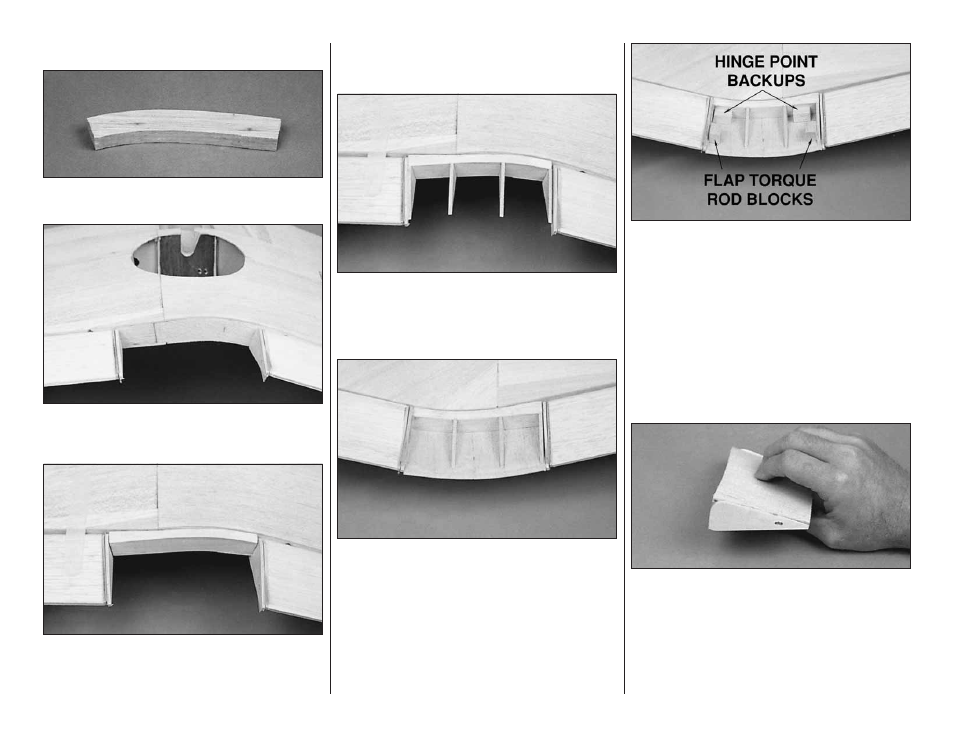

BUILD THE MIDDLE FLAPS

❏ ❏ 1. Glue two of the die-cut 1/4" [6.4mm] balsa middle

flap LE’s together to make a 1/2" [12.7mm] thick flap LE.

❏ ❏ 2. Tack glue a leftover piece of 1/16" [1.6mm] plywood

and a 1/8" [3.2mm] plywood flap end to the inboard end of

the outboard flap and the outboard end of the inboard flap.

❏ ❏ 3. Sand the ends of the middle flap LE so that it fits

between the inboard and outboard flaps. Also, sand the

flap LE to match the sweep of the wing TE and the taper

of the wing top and bottom.

❏ ❏ 4. Position the middle flap LE over the plan and mark

the rib locations.

❏ ❏ 5. Place a piece of wax paper or Plan Protector over

the plywood flap ends on the inboard and outboard flaps.

Tack glue the LE between the inboard and outboard flap

and glue the die-cut 1/8" [3.2mm] balsa flap ribs to the LE.

❏ ❏ 6. Make a bottom middle flap skin from a 3/32" x 3"

x 30" balsa sheet. Note the fore and aft grain direction.

Taper the aft edge of the skin to match the angle of the

flap ribs. Glue the skin to the middle flap frame.

❏ ❏ 7. From the 1/2" x 1/2" balsa stick, cut 3/4" [19mm]

long hinge point backups and flap torque rod blocks. Glue

the blocks on the back of the LE, end ribs and bottom skin.

Sand the flap torque rod blocks flush with the end ribs.

❏ ❏ 8. Make a top middle flap skin from the remaining

3/32" x 3" balsa sheet. Again notice the fore and aft grain

direction. Glue the skin to the middle flap frame.

❏ ❏ 9. Sand the top and bottom flap skin flush with the LE

and both end ribs.

❏ ❏ 10. Break loose the die-cut 1/8" [3.2mm] plywood flap

ends from the inboard and outboard flaps. Drill a 3/32"

[2.4mm] hole through the flap end ribs at the forward

punch marks only. Glue the plywood flap ends to the ends

of the middle flap, aligning the front of the plywood flap

end and the LE. The larger radius LE on the flap end goes

toward the bottom of the flap.