Install the flap controls – Top Flite TOPA0410 User Manual

Page 42

- 42 -

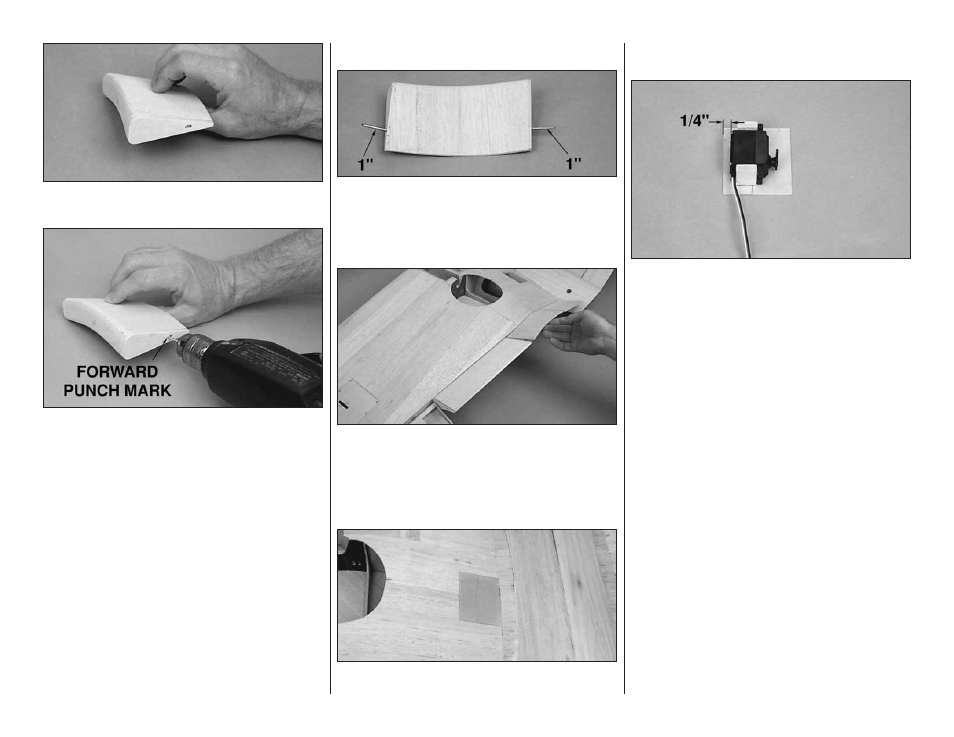

❏ ❏ 11. Use a sanding bar to sand the LE and flap skins

flush with the plywood flap ends.

❏ ❏ 12. Drill a 3/32" [2.4mm] hole through the flap end

ribs and flap torque rod blocks using the previously drilled

holes as a guide.

❏ ❏ 13. Install the hinges in the middle flap and wing as

previously done with the inboard and outboard flaps.

❏ ❏ 14. Temporarily install the middle flap on the wing.

Rotate the middle flap down noting where the flap LE

interferes with the wing TE ( between the hinges). The flap

LE will need to be rounded more in this area to clear the TE.

❏ ❏ 15. With all three flaps temporarily installed tightly

against the TE of the wing, sand the TE of the flaps so

that they are aligned. The middle flap will be slightly

curved at the TE.

❏ 16. Return to step 1 of Build The Middle Flaps and

build the other middle flap.

INSTALL THE FLAP CONTROLS

❏ ❏ 1. Cut 4" [101.6mm] from the non-threaded end of

two 4-40 x 12" [304.8mm] threaded pushrods. Cut both

4" [101.6mm] pushrods in half. Temporarily install a 2"

[50.8mm] flap torque rod in each end of the middle flap.

The rods should protrude out approximately 1" [25.4mm]

at both ends of the flap.

❏ ❏ 2. Assemble all three flaps with the flap torque rods

inserted into the slots of the inboard and outboard flap

slots. Temporarily install the assembly on the wing. Slowly

lower the flaps, checking that the flaps do not pull away

from the TE of the wing. If they do, you may need to

increase the radius on the LE of the flaps or enlarge the

slot in the inboard and outboard flaps.

❏ ❏ 3. Position the die-cut 1/16" [1.6mm] plywood flap

servo hatch in position on the bottom wing skin. Trace the

outline of the hatch onto the wing skin and carefully cut

out the bay, fitting the hatch into place.

❏ ❏ 4. Position the flap servo on the hatch so that the

bottom of the servo is 1/4" [6.4mm] from the edge of the

hatch. Drill several 1/16" [1.6mm] holes approximately

3/16" [4.8mm] deep into one end of the 5/16" x 3/4" x 7/8"

basswood servo mounting blocks. Roughen the servo

hatch where the mounting block will be attached. Apply

30-minute epoxy to the end of the mounting blocks,

making sure to pack epoxy into the 1/16" [1.6mm] holes.

Clamp the blocks to the hatch until the epoxy cures.

Important: Since both flap servo arms must move in the

same direction, when assembling the second flap servo

hatch, make sure the servo is mounted on the same side

of the hatch as the first one.

❏ ❏ 5. After the epoxy cures, drill a 1/16" [1.6mm] pilot

hole through the hatch into the center of each servo

mounting block. Countersink the holes in the flap servo

hatch. Secure each block to the hatch with #2 x 3/8" flat

head sheet metal screws.

❏ ❏ 6. Insert a 1/32" (.8mm] or 1/16" [1.6mm] temporary

shim between the servo and the plywood hatch. Drill 1/16"

[1.6mm] pilot holes and mount the servo to the mounting

blocks. Remove the shim and mark the top of the hatch in

line with the servo arm.

❏ ❏ 7. Tape the flap servo hatch in position and drill 1/16"

[1.6mm] pilot holes in each corner of the hatch and into

the hatch rails. Remove the hatch and countersink the

holes in the hatch for #2 x 3/8" flat head sheet metal

screws. Secure the hatch to the hatch rails with #2 x 3/8"

flat head sheet metal screws.