Build the outboard flaps – Top Flite TOPA0410 User Manual

Page 38

- 38 -

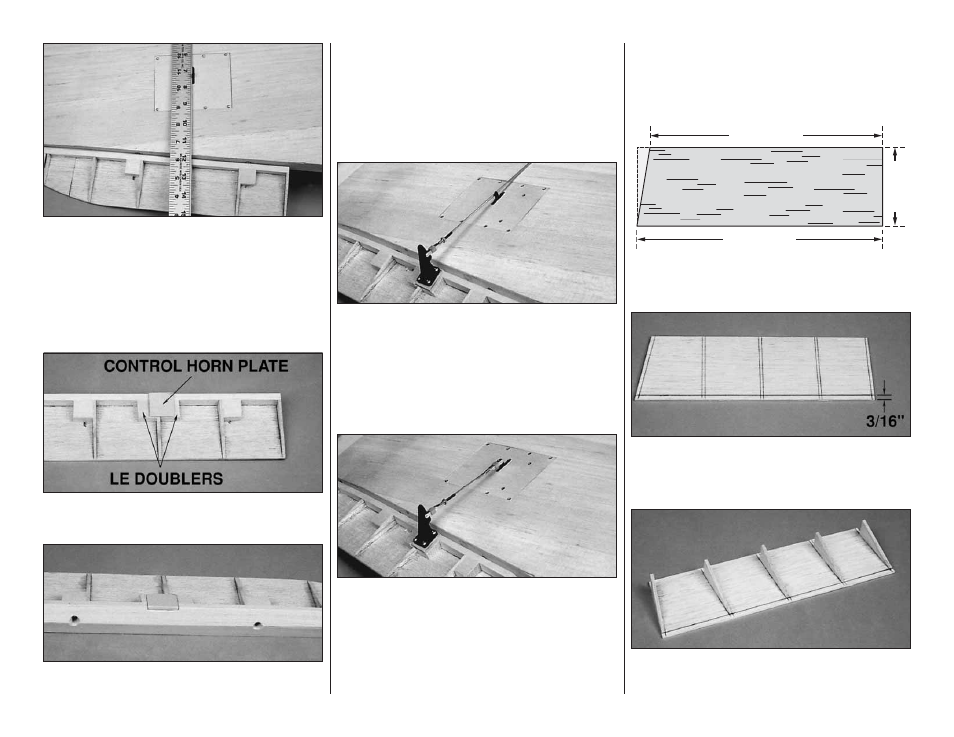

❏ ❏ 18. Reinstall the aileron on the wing. Place a

straightedge against the servo arm, parallel with the slot

in the servo hatch and mark the control horn location on

the LE of the aileron.

❏ ❏ 19. From the 1/2" x 1/2" [12.7mm x 12.7mm] balsa

stick, glue a LE doubler at the control horn location.

Remove the aileron and glue a LE doubler to the other

side of the aileron, at the same location. Trim and sand

the blocks flush with the aileron ribs.

❏ ❏ 20. Center the die-cut 1/8" [3.2mm] plywood control

horn plate on the mark, flush with the edge of the LE

taper. Mark the outline of the plate on the aileron.

❏ ❏ 21. Cut a 1/8" deep recess for the control horn plate.

The plate must fit flush with the top of the ribs and LE.

❏ ❏ 22. Cut a recess for the control horn plate on the

other side of the aileron.

❏ ❏ 23. Use epoxy to glue the control horn plates to the

ailerons.

❏ ❏ 24. Thread a 4-40 nut onto a 4-40 x 12" [4-40 x

304.8mm] threaded pushrod. Slide a silicone clevis

retainer onto the rod followed by a 4-40 threaded metal

clevis screwed on at least 14 turns.

❏ ❏ 25. Attach the metal clevis at the second hole from

the bottom on a heavy-duty nylon control horn. With the

pushrod aligned with the servo arm, position the control

horn on the aileron control horn plate so that the clevis

holes are aligned with the LE of the aileron. Mark the

control horn mounting holes on the control horn plate. Drill

a 1/8" hole through the aileron at each mark. Attach the

control horn to the aileron with four 4-40 x 1-1/4"

machine screws and a control horn backplate.

❏ ❏ 26. Attach a solder clevis to the outermost hole in

the servo arm. Center the servo arm and the aileron. Cut

the pushrod to the appropriate length. Remove the

pushrod and solder clevis from the wing and use silver

solder to solder the clevis onto the end of the pushrod.

Slide a silicone retainer over the solder clevis and reinstall

the pushrod on the servo arm and control horn.

❏ 27. Return to step 13 and install the other aileron servo.

BUILD THE OUTBOARD FLAPS

❏ ❏ 1. From a 1/2" x 15/16" x 18" balsa stick, cut a 9"

[228.6mm] long outboard flap LE. Save the remaining

piece for the inboard flap.

8-7/8" [225.4mm]

3" [76.2mm]

9-3/8" [238.1mm]

❏ ❏ 2. From two 3/32" x 3" x 18" balsa sheets, cut one

outboard flap skin from each sheet. Save the remaining

pieces for the inboard flap.

❏ ❏ 3. Position the flap skin over the outboard flap plan,

align the skin with the TE of the flap and mark the rib

locations on the skin. Draw a line 3/16" [4.8mm] from the

aft edge of the flap skin.

❏ ❏ 4. Glue the die-cut 1/8" [3.2mm] balsa flap ribs in

position, perpendicular to the flap skin aligning the aft edge

of the ribs with the line at the aft edge of the flap skin.