Final hookups and checks – Top Flite TOPA0410 User Manual

Page 51

- 51 -

Trim the MonoKote covering at the edge of the oil coolers.

Apply a thin coat of filler along the edge of the MonoKote

covering. After the filler dries, sand it flush with the

covering. Use masking tape to mask off the area around

the oil coolers. Spray a couple of coats of primer over the

oil cooler and filler. After the primer dries, remove the

masking and sand the primer to blend it into the covering.

Carefully paint the oil cooler and filler with LustreKote

paint. Avoid getting over spray on the rest of the wing.

The light blue on the Corsair, shown on the box, was

painted with a custom mix of Testors paint, applied with an

airbrush. After the paint dried, the decals were applied

and the panel lines were drawn on. The whole airplane

was then painted with mist coats of LustreKote Flat Clear.

Before painting the canopy, use scissors or a hobby knife to

trim along the molded cut lines. True the edges with your

bar sander and 220-grit sandpaper. Use 400-grit sandpaper

to scuff the frame portion of the canopy so the paint will

stick. We recommend painting the canopy frame with Pactra

Formula-U or Chevron Perfect Paint. Use masking tape or

frisket film to cover the portion of the canopy that is not to

be painted. If you are not sure that the paint is compatible

with the clear canopy, test the paint on a leftover piece of

canopy material and allow it to dry overnight.

For painting the pilot, we have discovered that acrylic

water base paints such as the types found at craft stores

work great. The acrylic paints look realistic on the pilots

because they are flat. Best of all, they cleanup with water.

We covered the cockpit floor (if a cockpit kit will not be

installed), sides and backrest with 600-grit sandpaper

glued in place with aliphatic resin glue.

APPLY DECALS

❏ 1. Study the plan and the photos on the box to visualize

where to place the decals.

❏ 2. Thoroughly clean your airplane before applying

decals.

❏ 3. Cut out the individual decals and apply them in the

locations shown on the box.

HINT: To apply decals accurately, use a permanent

marker to put small reference marks on the aircraft

outside the edge of the decal. Peel the decal backing off.

For larger decals, spray the aircraft and the glue side of

the decal with a mixture of soap and water. Carefully

“float” the decal into position. Use a damp paper towel to

squeegee the liquid out from under the decal working

from the middle outward. Remove the marks with

isopropyl alcohol.

FINAL HOOKUPS AND CHECKS

INSTALL THE HINGES

❏ 1. Starting with the elevators and stab, cut the covering

from the hinge holes.

❏ 2. Roughen the elevator torque rods wires with

sandpaper. Clean the torque rod wires with alcohol and a

paper towel to remove any oil residue.

❏ 3. Apply petroleum jelly to the hinge pivots to prevent

epoxy from gluing the hinge joints. Glue the torque rod

wires and hinges in the elevators and stab with 30-minute

epoxy.

❏ 4. Install the ailerons with their hinges. Repeat the

gluing technique described previously and allow the epoxy

to cure.

❏ 5. Install the rudder with it’s hinges. Repeat the gluing

technique described previously and allow the epoxy to

cure.

❏ 6. Use epoxy to glue the 1/16" [1.6mm] plywood flap arm

into each inboard flap LE. Make sure the clevis attachment

holes are equal distance from the LE of both flaps.

❏ 7. Use epoxy to glue the flap torque rods in the flap

center section.

❏ 8. Install the flaps with their hinges. Repeat the gluing

technique and process described previously.

INSTALL THE HARDWARE

❏ 1. Reinstall the fuel tank with foam padding (not

included) as follows: Insert two 12" pieces of fuel tubing

(not included) through the firewall. Connect one of the fuel

tubes to the fuel pick-up fitting and the other to the

overflow or pressure fitting. Insert the fuel tank into the

fuel tank compartment. Secure the tank with leftover sticks

glued to the fuse sides. Connect the fuel tubing from the

fuel pick-up fitting to the fuel fill valve. Route the overflow

line out the bottom of the cowl.

❏ 2. Reinstall the engine mount and engine. Apply thread

lock to the bolts holding the engine to the firewall.

❏ 3. Connect the fuel tubing from the fuel fill valve to the

carburetor. Connect the pressure line to the muffler if

using a glow engine.

❏ 4. Install the receiver switch and plug the receiver

battery into the switch. We recommend at least a 1200

mAh receiver battery be used. Wrap the receiver battery

in foam rubber and secure it under the fuel tank.

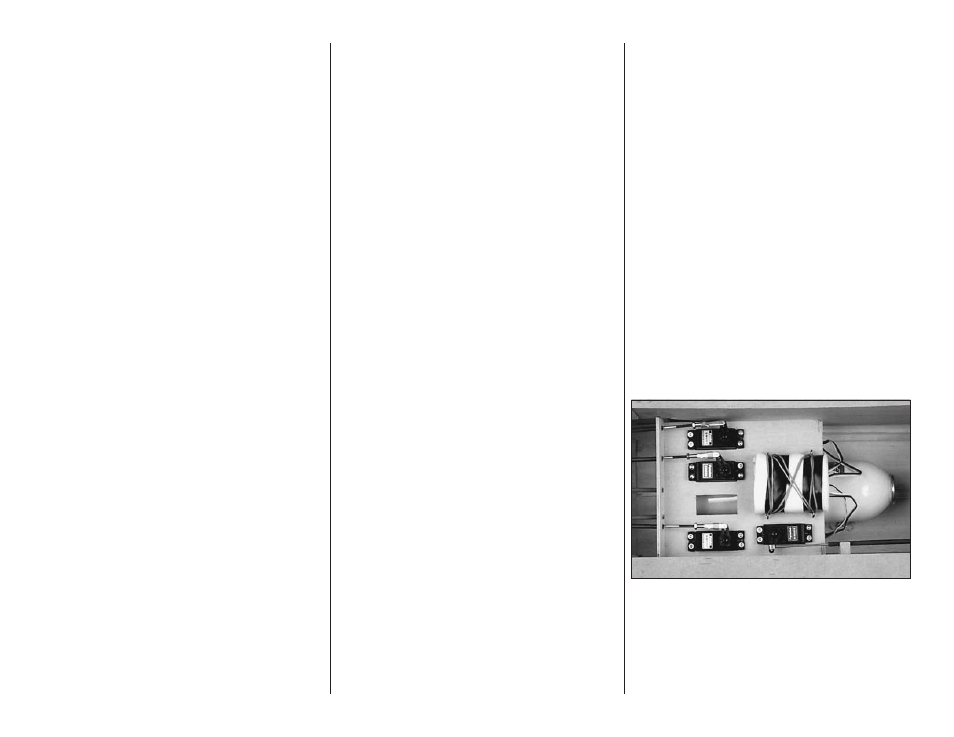

❏ 5. Install the servos in the radio tray, aileron servo

compartments and flap servo compartments. Route the

aileron and flap servo wires out of the wing center.

Reinstall the aileron servo horns.

❏ 6. Plug the servos and receiver switch into the receiver

and wrap it in foam rubber. The receiver can be secured to

the servo tray using eye screws and rubber bands (not

included).

❏ 7. Switch the radio system on and adjust the servos to

neutral. Use Y-harnesses to connect together the two

elevator servos, two flap servos, two aileron servos and

the rudder/tail wheel steering servos.