Assemble the cowl – Top Flite TOPA0410 User Manual

Page 48

- 48 -

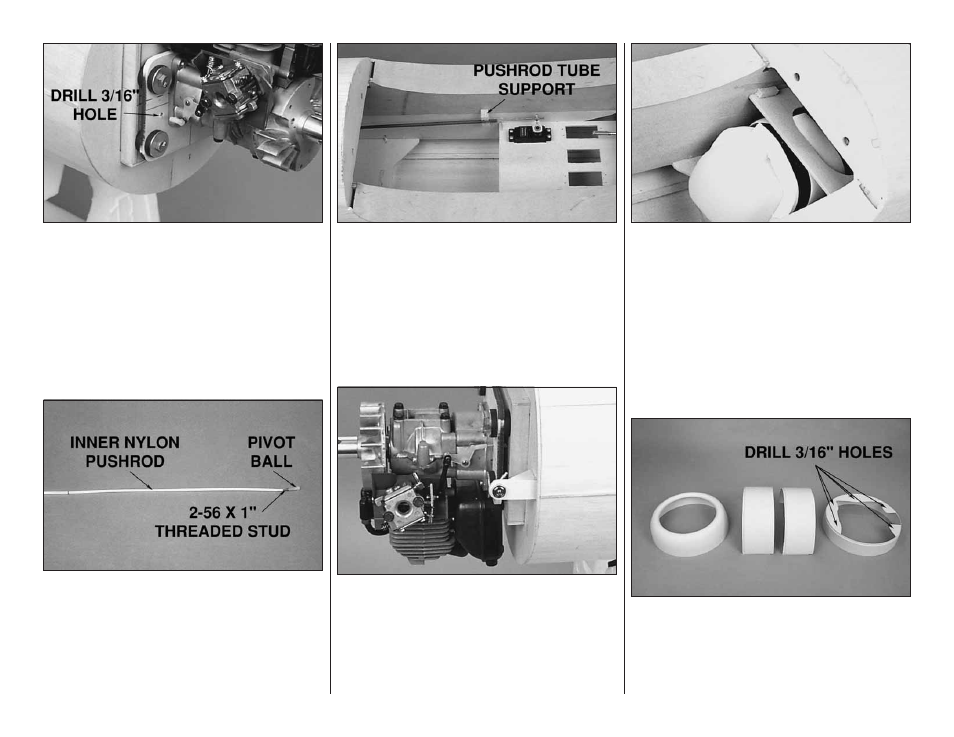

❏ 6. Install a 2-56 pivot ball on the throttle bellcrank. Snap

a ball end onto the pivot ball. Mark the isolation plate in

line with the ball end and drill a 3/16" [4.8mm] hole at the

mark through the plate and firewall. If you don’t have a

long 3/16" [4.8mm] drill bit you may need to remove the

engine to drill the holes.

❏ 7. Roughen a 3/16" [4.8mm] outer pushrod tube with

320 grit sandpaper. Glue the outer pushrod tube in the

3/16" hole in the firewall, flush with the front of the firewall.

Cut off the outer pushrod tube approximately 2" [50.8mm]

from the servo arm.

❏ 8. Screw a 2-56 x 1" [2-56 x 25.4mm] threaded stud 1/2"

[12.7mm] into one end of the inner nylon pushrod. Screw a

nylon ball end 14 turns onto the 2-56 threaded stud. Slide

the inner pushrod into the outer pushrod tube and connect

the ball end to the pivot ball on the throttle bellcrank.

❏ 9. Mark the inner pushrod 2" [50.8mm] from the throttle

servo arm. Remove the inner pushrod and cut the

pushrod 1" [25.4mm] shorter than the mark.

❏ 10. Screw a 2-56 x 12" [2-56 x 304.8mm] metal pushrod

14 turns into the end of the nylon inner pushrod. Slide the

inner pushrod into the outer pushrod tube. Attach a

Screw-Lock Pushrod Connector to the throttle servo arm

and slide the 2-56 metal pushrod through the pushrod

connector. Switch on the radio system and adjust the

throttle linkage so that the carburetor opens and closes

completely. Make an outer pushrod tube support from

leftover balsa and glue it to the outer pushrod tube and

fuse, close to the end of the outer tube.

❏ 11. Make a fuel fill valve mount from leftover 1/8"

[3.2mm] plywood. Install a fuel fill valve in the fuel fill valve

mount. If you are using a gas powered engine, be sure to

use a fuel fill valve designed for gasoline. Glue the mount

to F-1 so that the front of the valve is flush with the side of

the fuse.

❏ 12. Drill a clearance hole in the isolation plate and two

holes in the firewall for the fuel line to pass through.

Assemble your fuel tank. If you are using a gas powered

engine, be sure to use a fuel tank that is compatible with

gasoline. Wrap the fuel tank in foam rubber and insert it in

the front of the fuse. Mark the location for the die-cut 1/8"

[3.2mm] plywood fuel tank floor (TF). Remove the fuel

tank and glue the floor in place. Use several leftover

pieces of balsa to reinforce the joint between the fuel tank

floor and the fuse.

ASSEMBLE THE COWL

❏ 1. Trim the front, back and sides of the plastic cowl

along the molded cut lines. You can use a hobby knife to

carefully score along the cut lines and flex the plastic until

it breaks free, or use a small scissors to cut along the

lines. Hobbico

®

Curved Tip Canopy Scissors (HCAR0667)

work extremely well for this. Drill a 3/16" [4.8mm] mounting

hole at each dimple on the back cowl mounting lip.