Top Flite TOPA0410 User Manual

Page 37

- 37 -

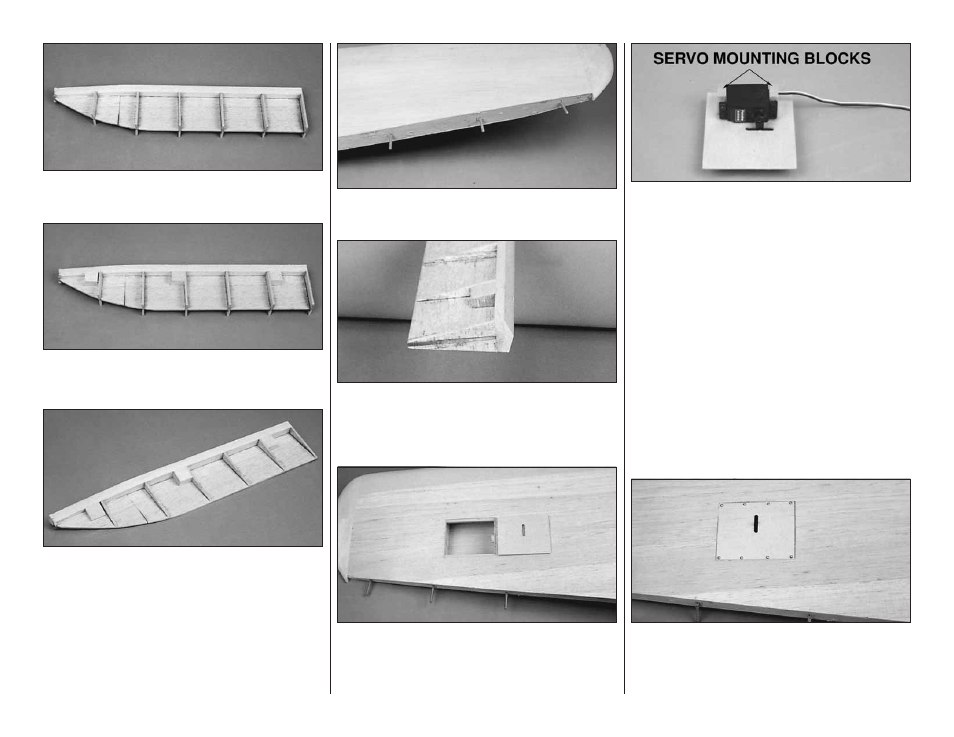

❏ ❏ 5. Cut aileron “ribs” from the 1/8" x 1/2" x 30" balsa

sticks. Glue the ribs to the aileron base at the previously

marked rib locations.

❏ ❏ 6. From the 1/2" x 1/2" [12.7mm x 12.7mm] balsa

stick, cut 3/4" [19mm ) long hinge point backups. Glue the

backups in position as shown on the plan.

❏ ❏ 7. Refer to the photo and the cross-section on the plan

to obtain the shape of the aileron. Use a razor plane and

sanding bar to “rough in” the shape of the aileron. Final

shaping will be done after the aileron is attached to the wing.

❏ ❏ 8. Hold the aileron in position against the TE of the

wing. Mark the hinge locations on the TE of the wing and

the LE of the aileron.

❏ ❏ 9. If you are using Robart Super Hinge Points, drill

3/16" [4.8mm] holes, centered on the TE of the wing and

LE of the aileron at each hinge location.

❏ ❏ 10. Insert the hinge points in the TE of the wing and

test fit the aileron on the wing, adjusting the hinge point

holes as necessary.

❏ ❏ 11. Sand the aileron LE to a “V” shape using the

cross-section on the plans as a guide.

❏ ❏ 12. Use a #11 knife to enlarge the opening of the

hinge points holes slightly to provide clearance for the

hinge pivot. Return to step 1 and build the other aileron.

❏ ❏ 13. Trace the outline of the die-cut 1/16" [1.6mm]

plywood aileron servo hatch accurately onto the wing

sheeting over its location. The hatch should be centered

on the hatch rails and between ribs R-4T and R-5T.

Carefully cut out the bay and fit the hatch into place.

❏ ❏ 14. Position the aileron servo on the hatch so that the

servo arm is centered in the hatch opening. Drill several

1/16" [1.6mm] holes approximately 3/16" [4.8mm] deep

into one end of the 5/16" x 3/4" x 7/8" basswood servo

mounting blocks. Roughen the servo hatch where the

mounting block will be attached. Apply 30-minute epoxy to

the end of the mounting blocks, making sure to pack

epoxy into the 1/16" [1.6mm] holes. Clamp the blocks to

the hatch until the epoxy cures.

❏ ❏ 15. After the epoxy has cured, drill a 1/16" [1.6mm]

pilot hole through the hatch into the center of each servo

mounting block. Countersink the holes to accept a #2 x

3/8" flat head sheet metal screw. We have found that a

Dremel #178 high speed cutter in a drill makes perfect

countersunk holes. Secure each block to the hatch with a

#2 x 3/8" flat head sheet metal screw.

❏ ❏ 16. Insert a 1/32" (.8mm] or 1/16" [1.6mm] temporary

shim between the servo and the plywood hatch. Drill 1/16"

[1.6mm] pilot holes and mount the servo to the mounting

blocks using the servo screws supplied with the radio

system. Remove the shim.

❏ ❏ 17. Tape the aileron servo hatch in position and drill

1/16" [1.6mm] pilot holes at the punch marks on the hatch

and into the hatch rails. Remove the hatch and

countersink the holes in the hatch. Secure the hatch to the

hatch rails with #2 x 3/8" flat head sheet metal screws.