Top Flite TOPA0410 User Manual

Page 49

- 49 -

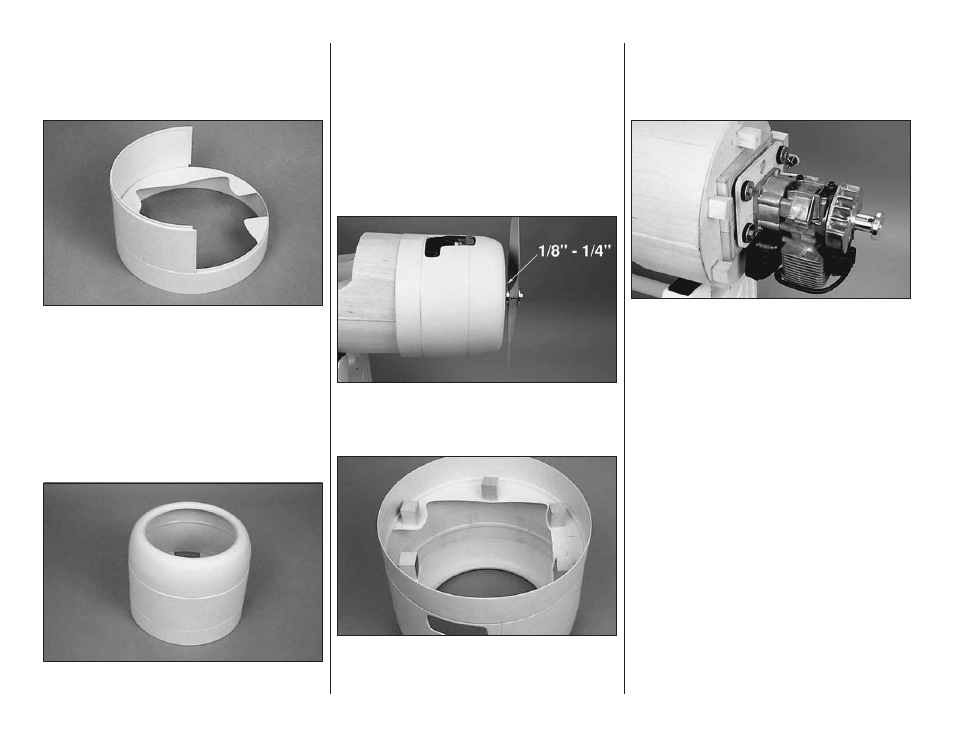

❏ 2. Use your bar sander to carefully true the edge of the

overlaps so when you glue them together the seam will be

as small and straight as possible. Sand all four pieces,

inside and out, with 320-grit sandpaper. Wash the cowl

pieces with soap and water and dry thoroughly.

❏ 3. Test fit one of the cowl sides on the cowl back,

making any adjustments as needed. Use thin CA to glue

the cowl side to the cowl back. Note: Do not use CA

accelerator. Use of accelerator on the ABS plastic may

cause cracks and/or prevent paint from adhering.

❏ 4. Test fit the other cowl side on the cowl back. The side

is molded slightly long to allow for trimming. Hold the

second cowl side on with masking tape and check the fit

of the cowl front. Make adjustments as necessary to the

side. When satisfied with the fit, use thin CA to glue the

second cowl side to the cowl back and the first cowl side.

❏ 5. After the CA has cured on the cowl sides, use thin

CA to glue the cowl front on the cowl sides.

❏ 6. Glue fiberglass behind the mounting holes and along

the seams on the inside of the cowl. For maximum

protection against stress cracks, you may apply 3/4oz.

fiberglass cloth to the entire inside surface of the cowl.

Adhere the cloth with thin CA or 30-minute epoxy thinned

with isopropyl alcohol.

❏ 7. Position the cowl on the fuse so that the front of the

drive washer is forward of the cowl front and centered in the

opening. Mount a prop on the engine and position the cowl

approximately 1/8" [3.2mm] to 1/4" [6.4mm] behind the prop.

The mounting lip on the cowl back may need to be trimmed

slightly if an engine other than a US Engines 41 is used.

❏ 8. Mark and trim the opening for the engine head and

exhaust. Start with a small hole and gradually increase its

size until the cowl fits. A Dremel

®

MultiPro

™

with a drum

sander works great for trimming holes in ABS cowls.

❏ 9. Drill a 7/64" [2.8mm] pilot hole centered in the end of

each of the five 3/4" x 3/4" x 1" hardwood mounting blocks.

Use #8 x 5/8" sheet metal screws to attach the mounting

blocks to the back of the mounting lip on the cowl .

❏ 10. Reposition the cowl on the fuse and check that the

drive washer is centered in the front of the cowl, the cowl

is centered on the fuse and that their is enough clearance

between the cowl and prop. You may need to trim the

blocks to allow the cowl to be positioned correctly.

❏ 11. When you are satisfied with the fit of the cowl, stand

the fuse up on its aft end. Apply a mixture of 30-minute

epoxy and milled fiberglass to the aft end of the mounting

blocks and carefully reinstall the cowl on the fuse. The

milled fiberglass will add considerable strength to the joint.

Check that the drive washer is centered in the front of the

cowl and the cowl around the fuse sides. Allow the epoxy

to cure thoroughly before removing the cowl.

❏ 12. Check the opening for the muffler and engine head,

trimming as necessary. Also cut openings for the fuel fill

valve, needle valve and any other accessories you will

need access to through the cowl.

❏ 13. Before painting the cowl, fill the seams and other

imperfections with auto body filler.

❏ 14. After the filler has cured, sand it flush with the

plastic. Wet sand the entire cowl with 400-grit sandpaper

in preparation for primer.