Top Flite TOPA0410 User Manual

Page 20

- 20 -

[3.2mm] plywood wing jigs under the wing tips at T-7 and

the 1-1/4" x 1-3/4" x 3-1/4" balsa block under the wing

center section TE. The wing tips must be seated on the

wing jigs and the jigs against the building table in order to

provide the proper amount of washout in the wing tips,

when sheeted. Note: The wing jigs can be tack glued to

the excess bottom sheeting, 1/16" [1.6mm] past rib T-7.

❏ 9. Before applying the top skin, rough cut the bottom

skin from over the aileron hatch openings.

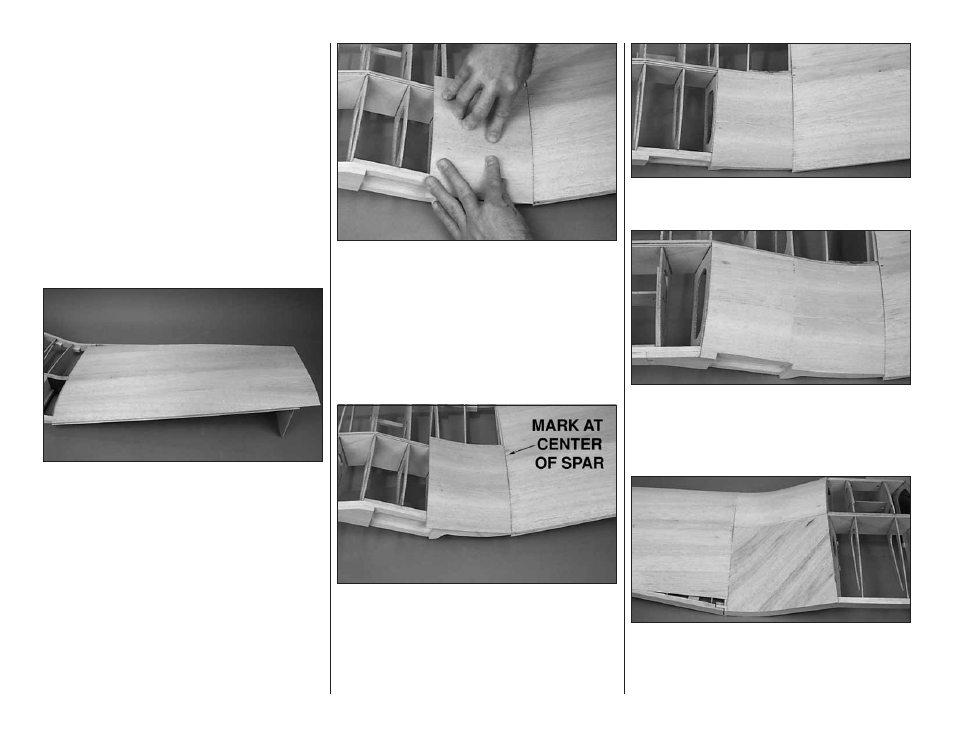

❏ ❏ 10. Hold an outer wing panel skin over the top of the

outer wing panel. The wood grain of the skin runs parallel

to the main spar. Mark the shape of the wing on the skin,

allowing about 3/16" [4.8mm] extra on all sides. On the

wing top, the outer wing panel is skinned from rib T-7 to

the center of R-1. We again, suggest adding a piece of left

over balsa to each side of R-1A.

❏ ❏ 11. Use thick CA to glue the wing skin to the LE first.

Use masking tape to hold it in position until the CA cures.

Next, wet the outside of the skin with warm water. Apply

thick CA to all the structure that will contact the bottom of

the wing skin from the main spar forward. Carefully press

the wing skin onto the structure and hold it in place until

the glue cures. Finally, carefully lift the aft edge of the

wing tip sheeting and apply thick CA to the remaining

structure and press the sheeting against the structure until

the CA cures. Use the remaining 3/32" x 3" balsa sheet

from step 4 to complete the sheeting at the TE .

Repeat steps 10 and 11 for the other wing tip panel.

❏ 12. Trim and sand the top and bottom wing tip skin flush

with the LE, TE and wing tip rib T-7.

❏ ❏ 13. The forward bent section of the wing is skinned

with the 3/32" x 5-7/8" x 7-1/2" balsa forward LE skin

assembled in step 3. The grain of the wood runs parallel

to the LE of the wing. The edge of the LE skin that fits

against the wing tip panel skin will need to be trimmed to

a curved shape. The best method to accomplish this is to

rub chalk along the edge of the wing tip skin. Wet the top

of the LE skin with warm water and carefully press the

forward LE skin into position. Remove the LE skin and trim

it along the chalk line. Check the fit and trim as necessary

to achieve a good fit.

❏ ❏ 14. Don’t worry about trimming the other edges of the

forward LE skin until after it is installed. Put a mark on the

edge of the wing tip panel skin, at the middle of the main

center spar. Wet the top of the LE skin again. Apply

medium or thick CA to the top of rib R-1, R-2, the forward

half of the center main spar and LE, from rib R-1 to

R-3. Press the LE skin onto the ribs, LE and center spar

starting at rib R-1 and working toward R-3.

❏ ❏ 15. Use a flexible straightedge to trim the LE skin

along the middle of the main center spar and along the

center of rib R-3. Glue the LE skin to R-3.

❏ ❏ 16. Use the chalk method to trim a second piece of

3/32" x 5-7/8" x 7-1/2" balsa sheeting to fit from R-3 to the

center of R-5.

Repeat steps 13 and 16 for the other end of the wing

center section

❏ ❏ 17. With the wood grain running diagonally to the TE,

use the chalk method to fit the previously assembled 3/32"

x 10- 1/8" x 10-1/8" top TE skin, to the TE of the wing

center section, between ribs R-1 and R-5. You will need to

wet the wood before trying to fit it in position.