Top Flite TOPA0410 User Manual

Page 52

- 52 -

❏ 8. Connect the elevator, rudder, aileron, flap and throttle

pushrods to the servo arms.

❏ 9. If you installed a gas engine, install an on/off switch

on the engine that can be manually turned off from the

outside of the cowl. Also an engine on/off switch must be

installed that can be operated from the transmitter. This

can be activated by a separate switch on the transmitter

or by the engine cut switch, found on some transmitters.

INSTALL THE RETRACTS

❏ 1. Follow the instructions included with the pull–pull

steering cable system to connect it to the retractable tail

wheel. Route the air retract tubing through the fuse and

attach it to the air cylinder on the tail wheel. Install the

retractable tail wheel in the fuse.

❏ 2. Install the tail wheel steering servo and connect the

pull–pull steering cables to the servo arm.

❏ 3. Make an air valve tray from leftover 1/8" [3.2mm]

plywood. This assembly can be placed in various

locations. On our test models it was placed in front of the

servo tray, beside the fuel tank. The air valve servo can be

mounted to the front of the servo tray and a hard wood

block glued to the plywood fuse crutch. Install the link rod

assembly between the servo and the air valve following

the retract manufacturer’s instructions. Be sure the servo

does not put side loads on the valve. This may cause the

valve to leak.

❏ 4. Follow the manufacturer’s instructions for connecting

the air line tubing to the air valve, air tank and retractable

tail wheel.

❏ 5. Install the retracts in the wing and route the air lines

through the holes previously drilled in the center spar and

ribs and out the center of the wing. We connected the air

lines in the wing with T-fittings and quick connectors.

❏ 6. Pressurize the air tank and cycle the retracts several

times to check that the retracts do not hang-up anywhere.

❏ 7. Use a solution of soap and water applied to all the air

line joints to detect air leaks. If the joint is leaking the soap

solution will bubble.

ATTACH THE CANOPY

❏ 1. Before permanently installing the canopy, securely

glue your pilot in place on the cockpit floor, if a full cockpit

will not be installed. For the most security, in addition to

glue, screw the base of the pilot to the cockpit floor with a

#4 sheet metal screw (not included) from the underside of

the cockpit floor. If you are installing a full cockpit kit, now

is the time to install it. Follow the installation instructions

included with the cockpit kit.

❏ 2. Place the canopy on the fuselage in the location

shown on the plan. Temporarily hold it in position with tape

or rubber bands.

❏ 3. Use a felt-tip pen to accurately trace the canopy

outline onto the MonoKote film covering. Remove the

canopy.

❏ 4. Without cutting into the balsa, use a sharp hobby

knife to carefully cut and remove a strip of covering 1/16"

[1.6mm] wide, approximately 1/32" (.8mm] inside of the

line you made. Wipe away the line with a paper towel

dampened with alcohol.

❏ 5. Reposition the canopy on the fuse and confirm that it

covers the exposed wood. Glue the canopy to the fuse

with a glue formulated for gluing on canopies such as

Pacer “Formula 560” canopy glue. Hold the canopy in

place with masking tape or rubber bands while the glue

dries.

COOLING NOTES

Model engines require sufficient cooling to provide reliable

operation, good performance and long life. There are two

problems which often present themselves in scale models

with cowlings: lack of air intake area and lack of air outlet

area. A rough rule in figuring such installations is to allow

twice as much outlet area as intake area.

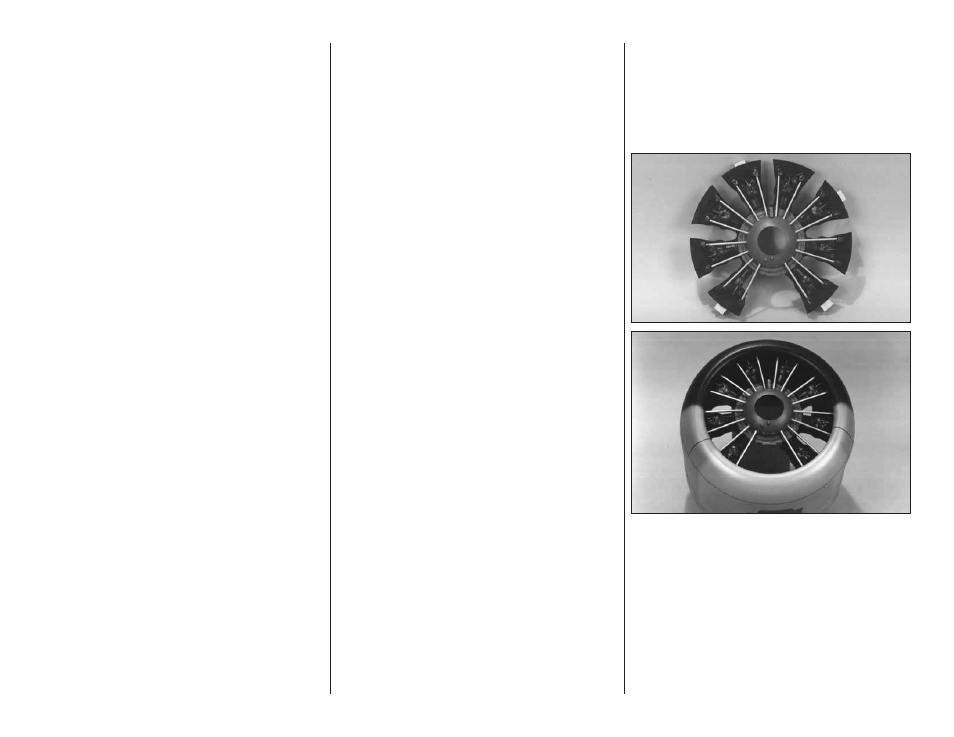

❏ The Corsair model, equipped with a single cylinder

engine, has too much intake area. To work around this

problem, the prototypes were equipped with baffles. A

baffle is used to block intake area where it offers little

benefit and to promote good airflow where it is needed (at

the cylinder head). To enhance the appearance of the

baffle, the Top Flite Corsair Radial Engine can be

mounted on the front of the baffle. The complete assembly

can then be glued in the cowl.

Ample air outlet area must be provided for good cooling.

The bottom of the cowl is a logical place for this since it is

least visible and an opening is needed for the engine

head on the US Engines 41.