40 - build the inboard flaps – Top Flite TOPA0410 User Manual

Page 40

- 40 -

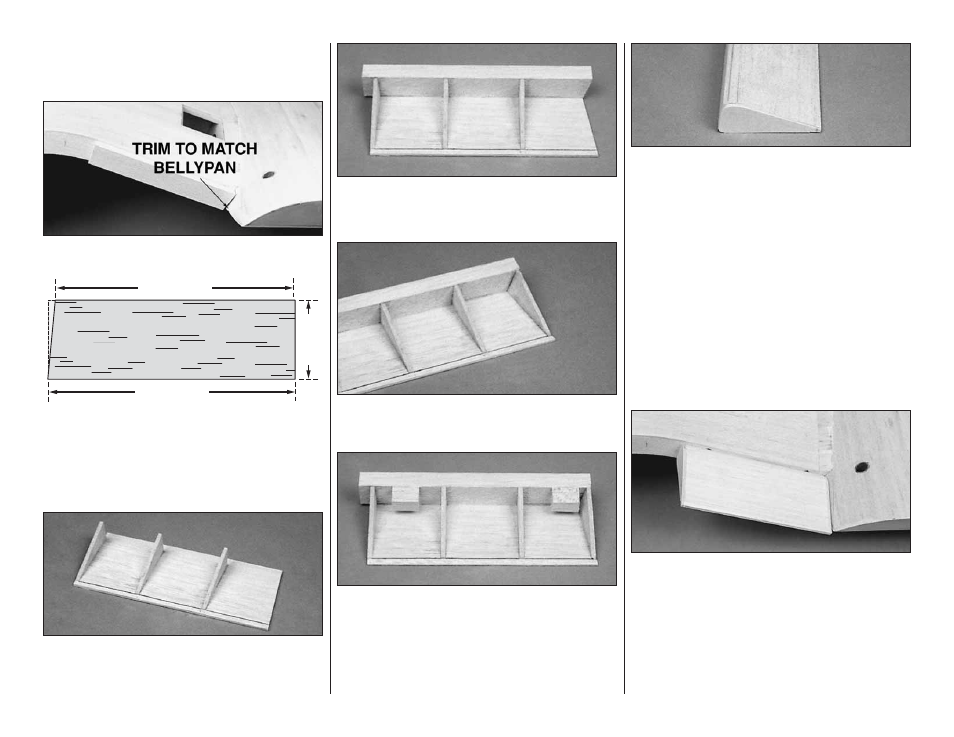

BUILD THE INBOARD FLAPS

❏ ❏ 1. From the remaining 1/2" x 15/16" balsa stick, cut a

6-7/8" [174.6mm] long inboard flap LE.

❏ ❏ 2. Sand one end of the stick to match the contour of

the belly pan at the TE of the wing.

6-1/4" [158.8mm]

3" [76.2mm]

6-1/2" [165.1mm]

❏ ❏ 3. From one of the remaining 3/32" x 3" balsa sheets,

cut in step 2 of Build The Outboard Flaps, make a top

inboard flap skin as shown.

❏ ❏ 4. Position the flap skin over the inboard flap plan,

align the skin with the TE of the flap and mark the rib

locations on the skin. Draw a line 3/16" [4.8mm] from the

aft edge of the flap skin.

❏ ❏ 5. Glue the three outer die-cut 1/8" [3.2mm] balsa

flap ribs in position, perpendicular to the flap skin. Align

the aft edge of the ribs with the line at the aft edge of the

flap skin.

❏ ❏ 6. Use a sanding bar to bevel the short edge of the

inboard LE so that it fits tightly against the forward edge of

the ribs and flap skin. The LE will hang over the forward edge

of the flap skin. When satisfied with the fit, glue it in position.

❏ ❏ 7. Glue the inner rib to the flap skin and flush with the LE.

❏ ❏ 8. Use a razor plane and sanding bar to bevel the LE

and the TE of the flap skin to the same angle as the ribs.

❏ ❏ 9. From the 1/2" x 1/2" balsa stick, cut 3/4" [19mm]

long hinge point backups and glue them in position on the

back of the LE. Sand the hinge point backups flush with

the LE and top of the ribs.

❏ ❏ 10. Glue the remaining balsa flap skin to the LE, ribs

and top flap skin.

❏ ❏ 11. Sand the LE and flap skins flush with the end ribs.

❏ ❏ 12. Glue the die-cut 1/8" [3.2mm] plywood flap ends

to the ends of the inboard flap, aligning the front of the

plywood flap end and the LE. The flap end with the two

punch marks goes on the outboard end of the flap with

the larger radius LE on the flap end toward the bottom of

the flap. Use a leftover piece of 3/32" [2.4mm] balsa to fill

in the corner between the LE and the flap skin.

❏ ❏ 13. Use a sanding bar to sand the LE and flap skins

flush with the plywood flap ends.

❏ ❏ 14. Drill a 3/32" [2.4mm] hole through the flap end, at

each punch mark. Use a hobby knife to finish making the

slot.

❏ ❏ 15. If you will be installing Robart Hinge Points, drill

3/16" [4.8mm] holes into the wing TE about 1/4" [6.4mm]

above the bottom of the bottom wing sheeting at the

previously marked hinge locations. These holes should

angle slightly toward the center of the wing. (See step 13

of previous section.)

❏ ❏ 16. Hold the inboard flap against the wing, so that it is

spaced approximately 1/16" [1.6mm] away from the belly

pan. Mark the hinge locations on the flap. Drill 3/16"

[4.8mm] holes in the LE of the flap in the same manner as

the wing. Trial fit the flap on the wing making any

adjustments as necessary. As the flap moves down make

sure the hinges do not pull out. If they do, increase the

radius on the bottom of the LE of the flap.

❏ 17. Return to step 1 of Build The Inboard Flaps and

build the other inboard flap.