TeeJet TASC-6600 User Manual

Page 62

C-4

TASC-6000, 6300, 6600

98-05010

Rev. - 1

C.2. FLOWMETER INSTALLATION

The installer should refer to the detailed instructions shipped with the particular device being installed. MIDWEST

TECHNOLOGIES recommends that these specific installation instructions be attached to this manual for future refer-

ence. There are, however, a few general mounting tips which should be considered for any flowmeter installation.

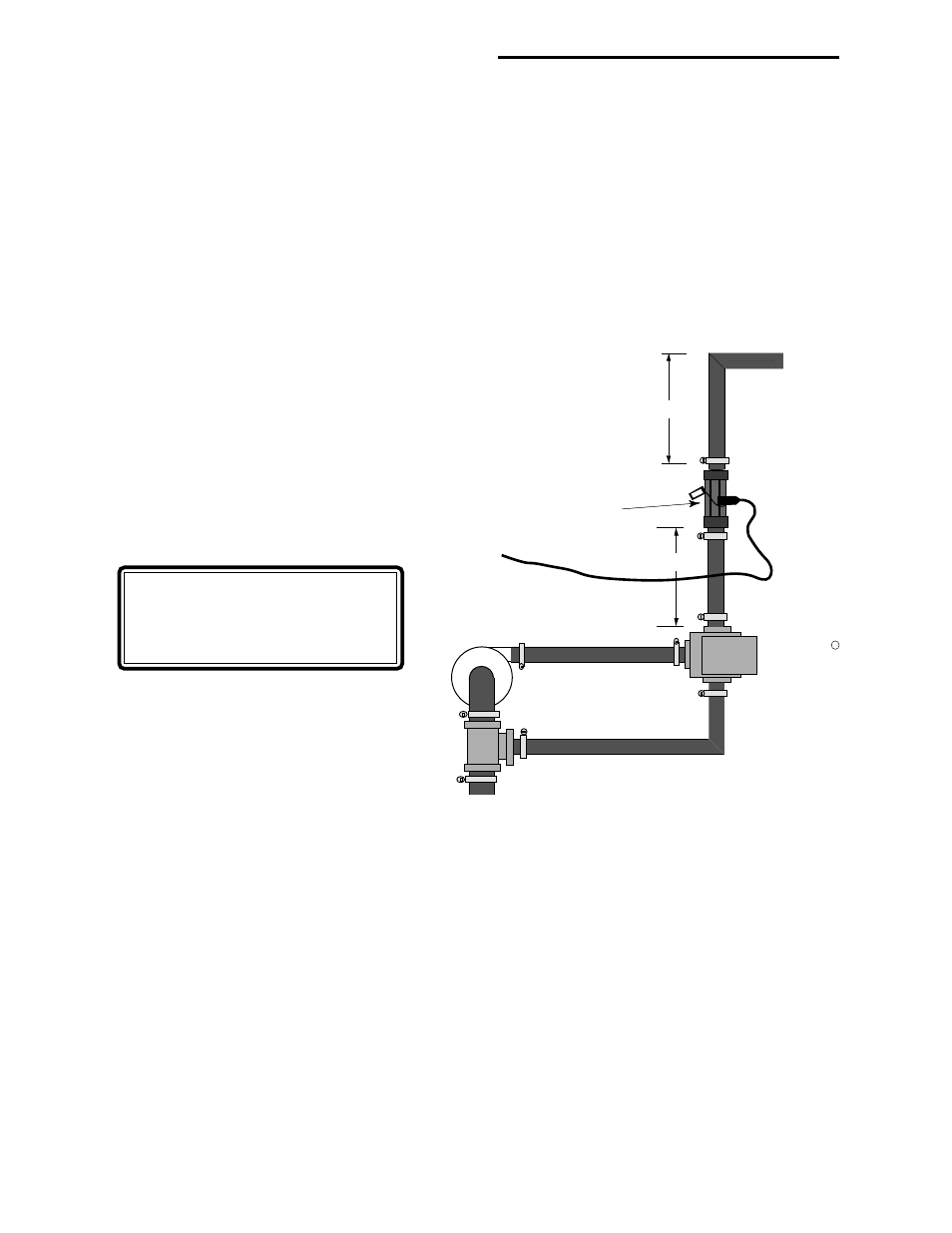

The accuracy of the flowmeter depends on a smooth, unobstructed flow through the device. Every effort should be made

to mount the flowmeter in a straight section of the main boom supply line with at least twelve inches of straight flow

upstream from the device and at least six inches of straight flow downstream from the device. Sharp bends in the flow

stream caused by valves, kinks, elbows, tees, etc., can seriously degrade the performance of the flowmeter. Addition-

ally, if the flowmeter being installed is sensitive to the direction of flow, it will be marked with an arrow. These devices

should always be installed with the arrow pointing in the direction of normal flow.

>12 inches

> 6 inches

FLOWMETER/

PRESSURE SENSOR

TO BOOMS

MAIN PRODUCT

PUMP

BYPASS LINE

AUTO RANGE

VALVE

R

Signal cable

to console

PUMP DISCHARGE

The flowmeter must provide the TASC Control Console with a continuous measurement of total liquid actually dis-

charged by the sprayer. This includes both the main carrier and the injected chemical, after the two are mixed. To

accomplish the required measurement, the flowmeter must be installed in the main boom supply line, upstream from the

individual boom shut off valves and downstream from the flow control valve and pump bypass line, if used (See figure

above).

The flowmeter should be installed in a location that will physically protect it from damage and allow liquid to drain

away when the sprayer has been flushed and secured at the end of an operating day. Keep the flowmeter from lying in

a low section of tubing. This is particularly important in cold weather, when water could freeze in the flowmeter and

damage the internal mechanism. It is also important when applying chemical suspensions which may settle and obstruct

the flowmeter if they don't drain away. A straight, vertical section of the main boom supply line, is the ideal location for

the flowmeter. Firmly support the main boom supply line in the vicinity of the flowmeter to protect it from deforming

and vibration.

NOTE: THE FLOW METER MUST

BE MOUNTED SO THAT IT WILL

DRAIN COMPLETELY WHEN THE

SPRAYER IS NOT OPERATING!