TeeJet TASC-6600 User Manual

Page 17

2-5

TASC-6000, 6300, 6600

98-05010

Rev. - 1

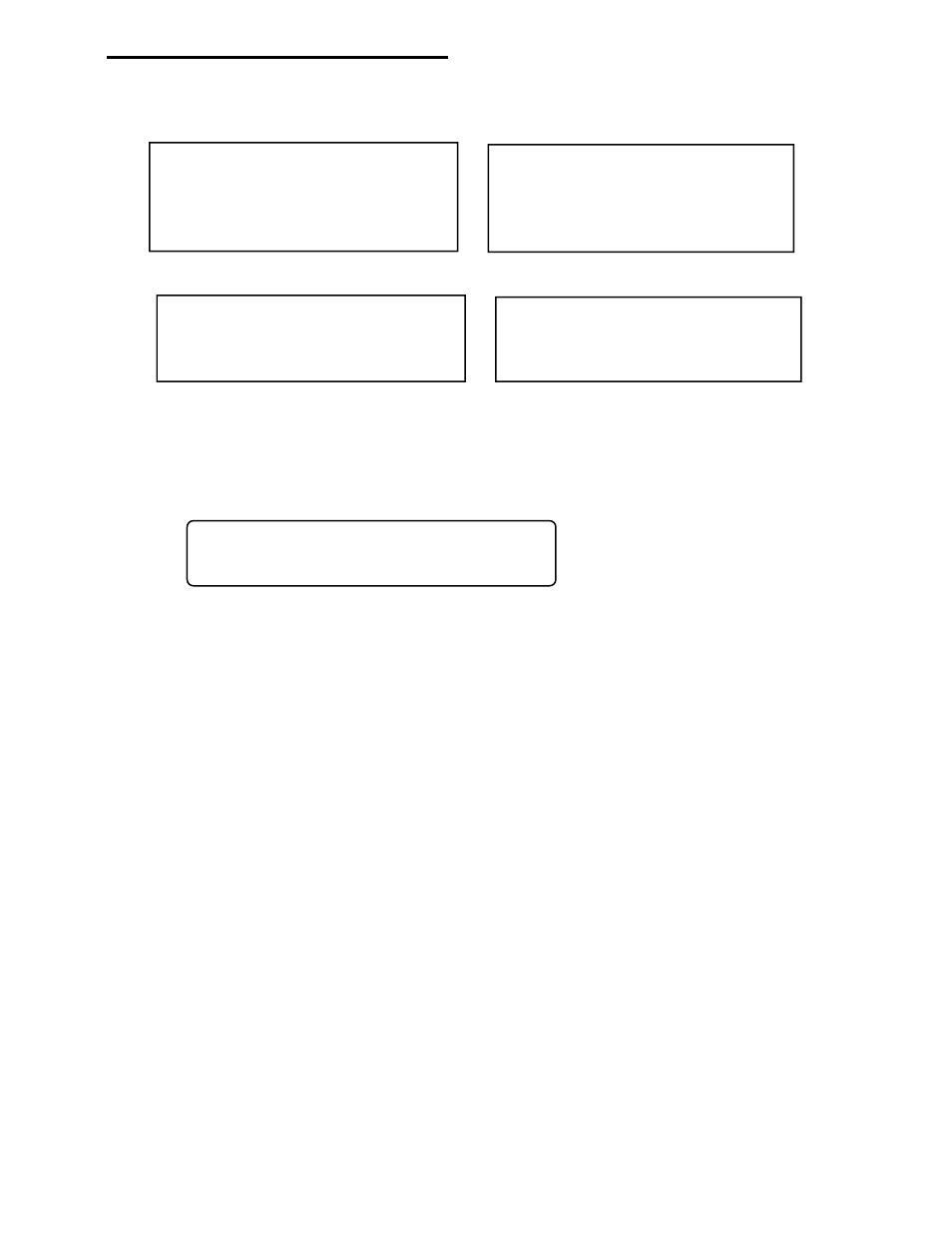

2.6.1 TYPICAL FLOWMETER CALIBRATION NUMBERS (for water)

Standard Flowmeters

SIZE

SUPPLIER

CAL.#

SIZE

SUPPLIER

CAL.#

.75 inch

(Mid-Tech)

396.9

3.00 inch(Mid-Tech)

5.0

1.00 inch(Mid-Tech)

153.1

1.50 inch(Mid-Tech)

38.8

1.25 inch(Raven)

75.0*

2.00 inch(Mid-Tech)

23.8

3.00 inch(Raven)

16.4*

Mid-Tech Rapid Check Flowmeters

SIZE

RANGE

CAL#

SIZE

RANGE

CAL#

1.00 inch0.75 - 5 gpm

3200

1.50 inch2.6 - 53 gpm

361.9

1.00 inch2.5 - 25 gpm

612.4

1.50 inch 9 - 90 gpm

155.2

1.50 inch2.5 - 16 gpm

800

2.00 inch 20.0 - 195 gpm

94.5

* Raven flow meters, use the factory calibration number divided by 10. All other flowmeters use the manufacturers'

supplied information regarding the pulses per gallon (usually provided on a tag on the flowmeter).

Use the following procedure to enter the typical flowmeter calibration number.

A. Set the Console to the following positions;

Power

ON

Mode Selector

SET- UP

Display Selector

CARRIER, TOTAL APPLIED

B. Use the INC/DEC switch to select the desired flowmeter calibration number.

2.6.2 FLOW METER CALIBRATION PROCEDURE

Field calibration of the TASC flowmeter is relatively simple. Operators have successfully performed flowmeter calibrations

using a second, calibrated, flowmeter, using a truck scale and calculating volumes based on weight and density of the

liquid discharged, and by discharging into a marked, calibrated tank.

A method such as the following is recommended. It is necessary to pump and measure at least 100 gallons (400 liters) and

as much as 500 gallons (2000 liters), depending on the accuracy required. The better the measurement accuracy of actual

discharge and the more material pumped, the more accurate is the resulting calibration. For example: an actual measure-

ment accurate to within 5 gallons (20 liters) while pumping and measuring 500 gallons (2000 liters) yields an accuracy of 1

%. A result within 5 gallons (20 liters) while using only 100 gallons (400 liters) results in an error of 5 %.

A. Disconnect the line to one of the booms and direct the output to an appropriate catch basin through a manually

adjustable valve. Adjust the valve for smooth flow with no error messages on the console.

B. Verify that the boom switches and injection pump switches are OFF; turn the Control Console ON; select the

SET-UP mode; rotate the display selector switch to CARRIER, TOTAL APPLIED.

C. The current flowmeter calibration number is displayed. Make sure it is the recommended initial calibration number

for the flowmeter installed in the system (Refer to the metal tag attached to the flowmeter.). Use the INC/DEC

switch to adjust as necessary.

D. Select OPERATE with the mode selector switch. Hold the DEC switch down for three to five seconds to zero the

accumulated gallons display.

E. If the "HOLD on All Booms OFF" function has been activated for carrier valve, reset it to "CLOSE". (See section

2.9.2 of the manual if you are unsure about this; the factory setting is "CLOSE").