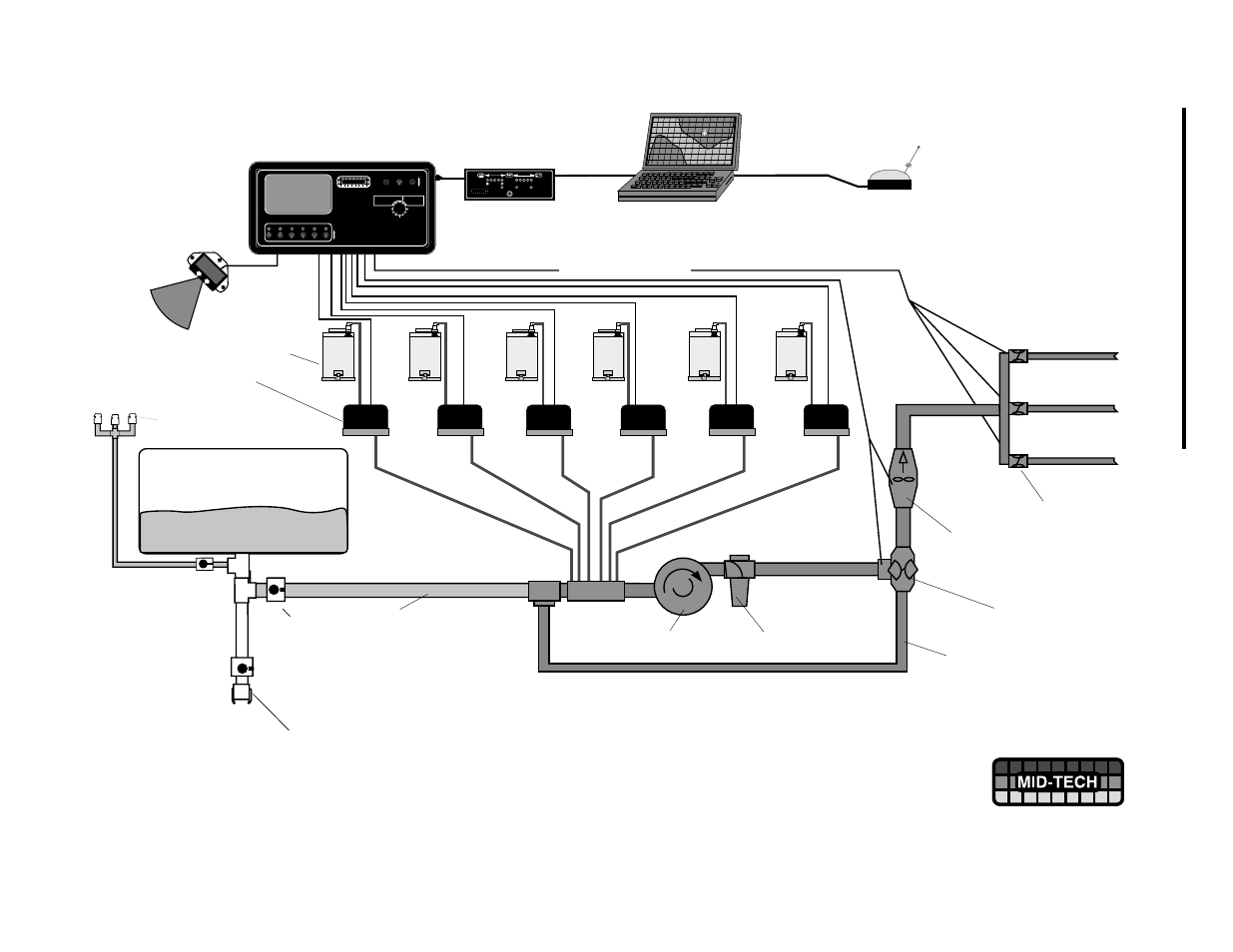

Tasc-6600 control system, Midwest technologies, inc, In-line filter – TeeJet TASC-6600 User Manual

Page 49: Bypass line suction line

A-3

TASC-6000, 6300, 6600

98-05010

Rev. - 1

TASC-6600 Control System

Carrier Pump

Boom Valves

(Up to 9 Total)

CarrierTank

FLOW METER

In-Line Filter

AUTO-RANGE

FLOW CONTROL VALVE

Bypass Line

Suction Line

GROUND

SPEED

SENSOR

TASC CONSOLE

To Spray

Booms

CHEMICAL INJECTION PUMPS

CHEMICAL INJECTION TANKS

MID-TECH

MIDWEST TECHNOLOGIES, INC.

CHEMICAL APPLICATORS

1

2

3

ON

OFF

Alt.-

Rate

TASC-6600

TOTAL

APPLICATION

SPRAYER

CONTROL

%Rate

DISPLAY SELECTOR

Speed

Area

Width

Distance

Chem. Applied

Test

Speed

Prime

Total Applied

Chem. Rate

Appl. Rate

CHEMICALS

CARRIER

OFF

SET- UP

DEC.

ON

OPERATE

INC.

1 2 3 4 5 6 7 8 9

BOOMS

Scan

4

5

6

TASC DATA LINK

INTERFACE

COMPUTER WITH

MAPPING PROGRAM

DGPS Receiver

and antenna

MIDWEST TECHNOLOGIES INC.

2733 East Ash Street

Springfield ILL - (217) 753-8424

www.mid-tech.com

EXTERNAL DEVICE

DATALINK

TASC CONSOLE

RTS

CTS

INVALID

EXTERNAL

DATA

INVALID

CONSOLE

DATA

INVALID

DATALINK

DATA

LOCAL

CONTROL

EXTERNAL

ENABLE

DATA FLOW

DATA FLOW

#405-0069

DATALINK INTERFACE

MID-TECH

MIDWEST TECHNOLOGIES, INC.

BOOM STATUS CABLE

®

Quick Fill Port

Must be located between the Carrier Tank and Main Shut Off Valve.

Main Shut Off Valve

Must be closed during refilling to

prevent possible back wash of

chemicals into the Carrier Tank.

NOTES:

* Injection Hose lengths should be kept to a minimum to reduce the amount of chemical required to fill the lines.

However, be sure to allow enough length, so as to

not bind or stretch the hose when raising or lowering the boom.

** Upstream injection for Non-Compatible Chemicals (e.g. Atrazine when using an Atrazine product and 2-4D).

There must be an in-line strainer between the Non-Compatible injection point and the other injection points

Fresh Water Flush Ports

A.2 TASC 6600 SYSTEM PLUMBING DIAGRAM