TeeJet TASC-6600 User Manual

Page 20

2-8

TASC-6000, 6300, 6600

98-05010

Rev. - 1

2.8.1 TYPICAL PUMP CALIBRATION NUMBERS, PC#

The pump calibration number (PC#) is a value that relates to the volume of chemical output during each revolution of the

injection pump and is used by the TASC Control Console to determine each pump’s actual discharge rate. Pump calibra-

tion numbers will differ slightly from one pump to the next due to variations in plumbing, tube size, pump chambers, etc.

The following values are typical PC#’s you can expect to see after performing the field calibration procedure. If your pump

calibration number differs from the typical range, check the calibration. Use these numbers for your initial pump calibra-

tion numbers, before conducting the actual prime or pump calibration procedure.

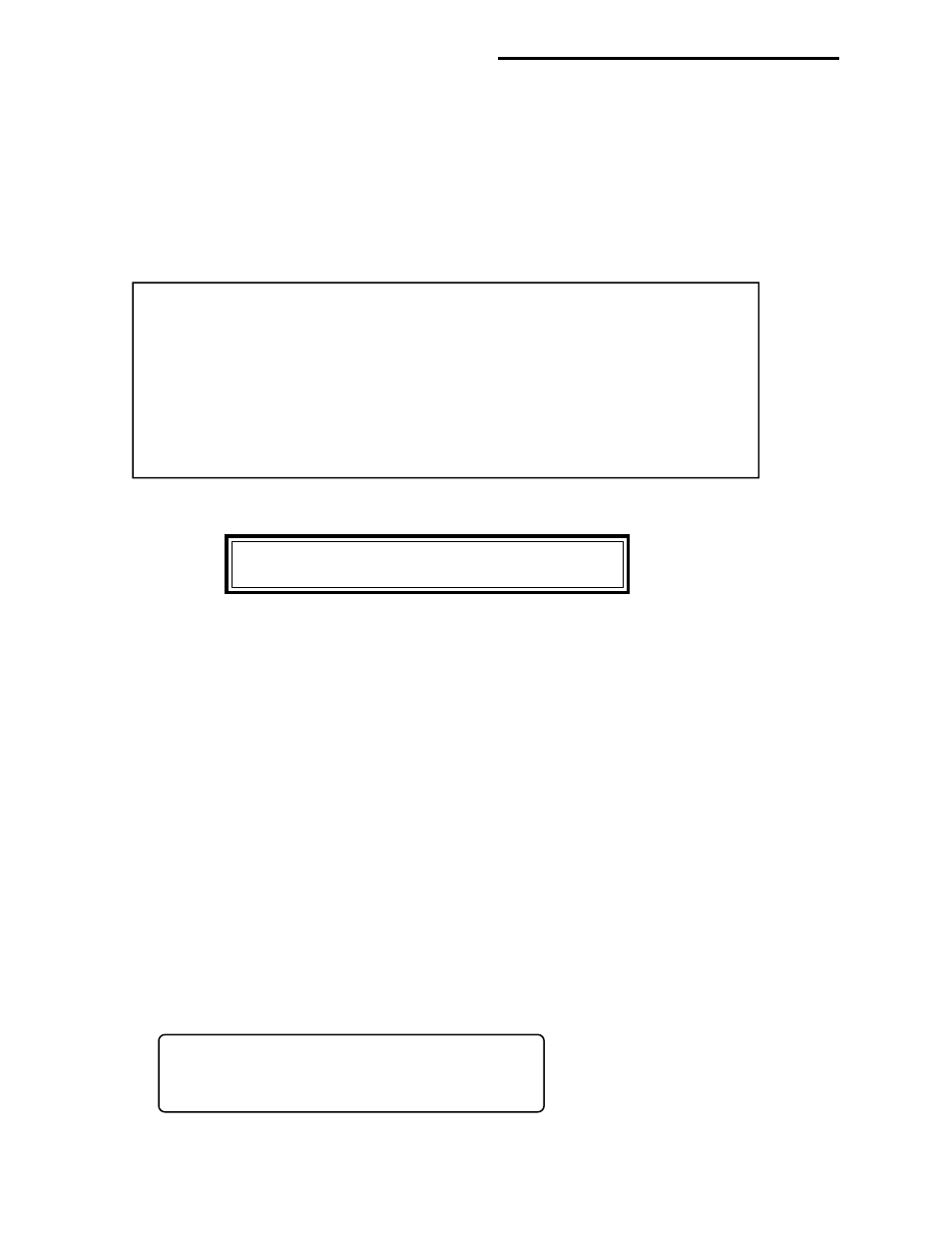

MODEL #

DESCRIPTION

TYPICAL PC# RANGE

ISC-20 PUMP

0.2 to 20-Oz./Min. (1/4"Dia. Tube)

32.0

27/37

ISC-50 PUMP

2.6 to 53-Oz./Min. (1/4"Dia. Tube)

110.0

100/120

ISC-50 PUMP

1.5 to 29-Oz./Min. (3/16"Dia. Tube) 65.0

58/72

ISC-100 PUMP

1.0 to 100-Oz./Min. (3/8"Dia. Tube) 145.0

130/160

ISC-150 PUMP

1.5 to 150-Oz./Min. (3/8"Dia. Tube) 145.0

130/160

ISC-200 PUMP

6.4 to 128-Oz./Min. (3/8"Dia. Tube) 285.0

256/314

ISC-200 PUMP

10.7 to 213-Oz./Min. (1/2"Dia. Tube)485.0

436/534

ISC-350 PUMP

22.0 to 220-Oz./Min. (3/8"Dia. Tube)285.0

256/314

ISC-350 PUMP

37.0 to 370-Oz./Min. (1/2"Dia. Tube)485.0

436/534

2.8.2 PUMP CALIBRATION, FIELD PROCEDURE

The following field procedure is recommended to check or calibrate the injection pumps. This procedure requires a catch

basin or container of at least 60 Oz. with graduation marks. In this example, a 56 Oz. test is described. There is nothing

magic about the 56 Oz. number, in fact, collecting more material leads to smaller measurement errors. However, it is

important to get a very accurate measurement of the volume of fluid (Fl. oz.) collected. In this example we will be calibrat-

ing Pump #1, the procedure is the same for all pumps.

NOTE: MID-TECH suggests doing all calibrations using water to keep the procedure as simple and safe as possible;

however, it may be necessary to calibrate with the actual chemical if it is an extremely thick, heavy or viscous fluid.

Check the current Pump Calibration Number and Application Rate (pump to be calibrated), Boom Width “C”, and Test

Speed values. These should be typical for your sprayer operations. If not, reset them to a typical value, (Refer to Sections

2.3.2. & 2.5 to view and enter these values).

The calibration is conducted with the vehicle STOPPED and the main carrier pump NOT running. To safeguard against

backflushing and siphoning, SHUT OFF the feed line from the main tank to the main pump.

NOTE: Thoroughly flush all injection lines and fill with clean water before performing calibration procedure.

A. Make sure all chemical containers are filled with fresh, clean water, and they are connected to the proper injection

pumps. Turn all booms OFF (boom width "C" is used.)

B. Set the control console switches as follows:

Power

ON

Mode Selector

OPERATE

Display Selector

CHEMICALS, CHEM, APPLIED

Pump Switch #1

CENTER, ON POSITION

The accumulated volume for pump #1 will be displayed.

TO ENSURE AN ACCURATE CALIBRATION, PLEASE FOL-

LOW THE PROCEDURE EXACTLY!