Boom indicators injection pump switches – TeeJet TASC-6600 User Manual

Page 10

1-4

TASC-6000, 6300, 6600

98-05010

Rev. - 1

1.5 BOOM SECTION “ON/OFF” INDICATORS

MID-TECH

MIDWEST TECHNOLOGIES, INC.

CHEMICAL APPLICATORS

1

2

3

ON

OFF

Alt.-

Rate

TASC-6600

TOTAL APPLICATION

SPRAYER CONTROL

%Rate

DISPLAY SELECTOR

Speed

Area

Width

Distance

Chem. Applied

Test

Speed

Prime

Total Applied

Chem. Rate

Appl. Rate

CHEMICALS

CARRIER

OFF

SET- UP

DEC.

ON

OPERATE

INC.

1

2

3

4

5

6

7

8

9

BOOMS

Scan

4

5

6

.

-Ac

Flow

RATE

Gal./

®

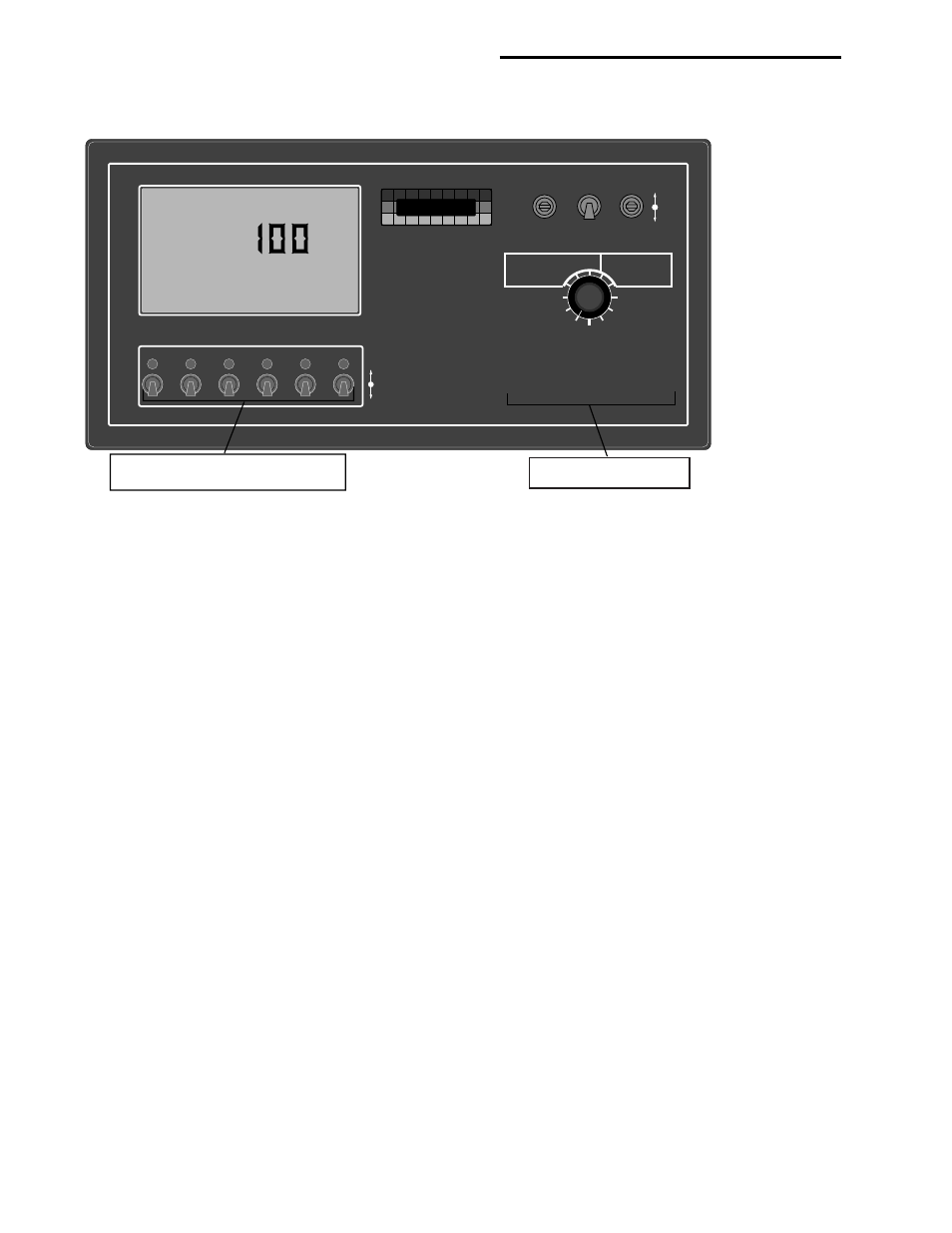

Boom Indicators

Injection Pump Switches

The boom section on/off indicators (lower right, labeled BOOMS), indicate which boom sections are active (turned on).

There is a maximum of nine boom section positions available.

1.6 INJECTION PUMP SWITCHES (TASC 6300 and 6600 only)

(Refer to Appendix D for these switch functions in "Handgun Mode".)

The injection pump switches (lower left) are used to activate the injection pumps. Up to six separate injection pumps can

be controlled by the TASC console. Each pump has its own product switch and indicator light. When the switch is in the

down position, the injection pump is OFF. When the switch is in the ON position, the pump is pumping at the standard

target rate, (the pump indicator light glows steadily). When the switch is in the Alt. Rate position, the pump is pumping

at the alternate target rate (the indicator light blinks and the console beeps periodically, indicating a non-standard

operation).

1.7 STATUS SWITCH

An externally mounted status switch can be used to control the injection pumps and the flow control valve. The switch

must present a positive voltage (+12.0 VDC) status on the green or white wire of the boom interface cable. As long as

this condition is present, TASC operates normally. If the voltage is interrupted, the TASC automatically stops the

injection pumps. At the same time, TASC either "CLOSE's" the flow control valve or "HOLD's" it in its current position,

depending on the response selected by the operator (See Section 2.9).

The intent of this feature is to allow the operator to control the operation of TASC through the normal operation of the

vehicle. The status switch can be used to sense the "ON"/"OFF" condition of the main vehicle pump or the switch may

sense an implement "UP"/"DOWN" condition. Use of the status switch can lessen the operator's work load under certain

conditions.