0 uncrating and preparation -8, 1 uncrating and inspecting, 2 preparing for installation – Reznor UDBS Unit Installation Manual User Manual

Page 7: Field-installed parts

Form I-UDB, P/N 202658 R14, Page 7

High Altitude Kit, Option DJ20 or DJ21

If the heater is being installed at an elevation above 2000 ft (610M), the input rate will

have to be derated. This is done by adjusting the valve outlet pressure.

In addition, if the heater is being installed at an altitude above 6000 ft (1830M), the

pressure switch will have to be changed. If ordered with the unit as Option DJ20 or

DJ21, the pressure switch is shipped separately for field installation.

Adjusting the valve outlet pressure is done after the heater is in operation; follow the

instructions in Paragraph 6.1

.

Capacities and inputs for derated units are also listed in

Paragraph 6.1.

Gas valve adjustment

for high altitude can

only be done after

heater is operating;

see Paragraph 6.1.

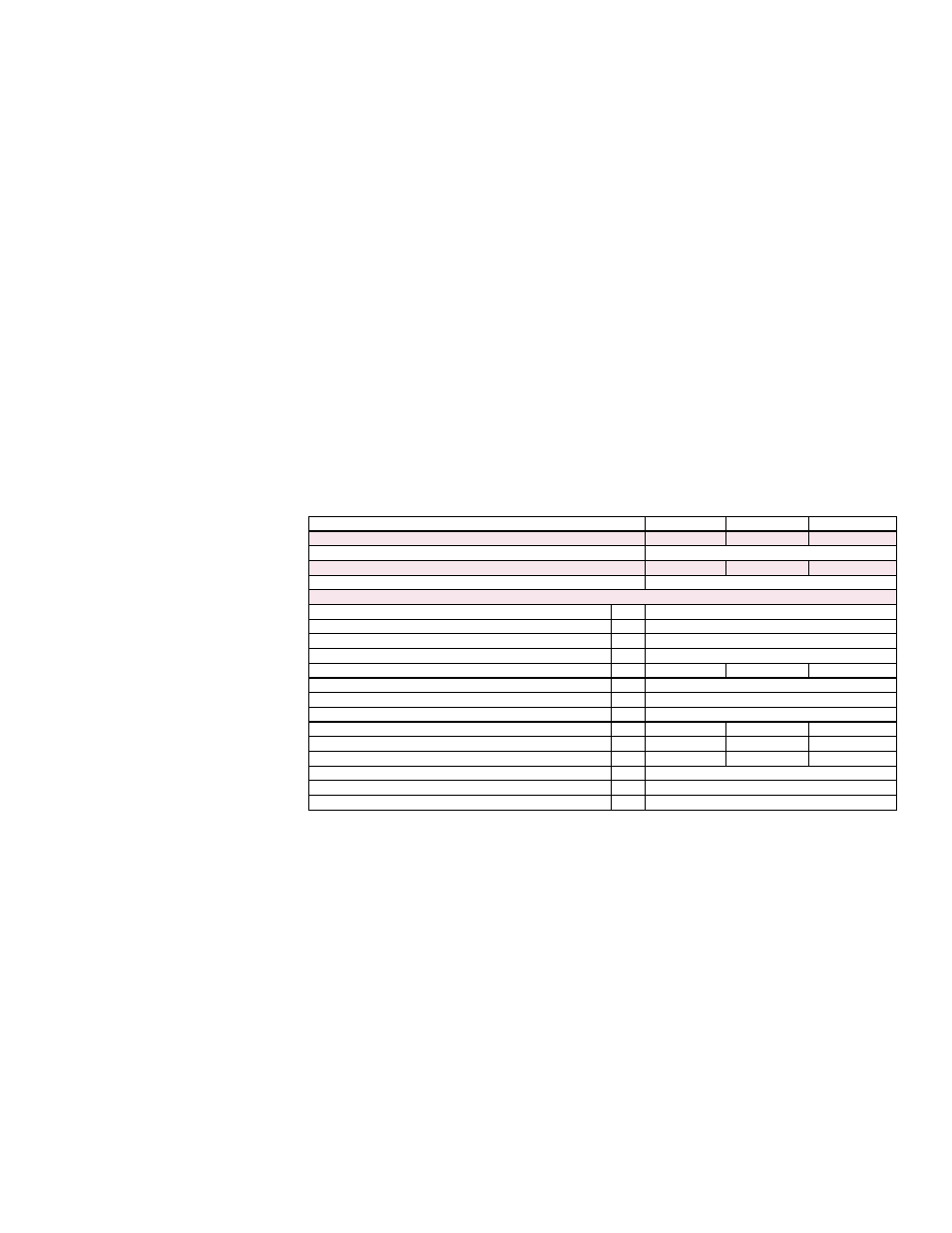

Model UDB Size

150-200

225-250

300-400

Shipped-Separate Package P/N for 460V/3ph Supply

198503

198504

198505

460V - 120V Transformer

P/N 11100

Shipped-Separate Package P/N for 575V/3ph Supply

198506

198507

198508

575V - 120V Transformer

P/N 202056

Components of both the 460V and the 575V Shipped-Separate Pacakge (above):

Description of Parts

Qty

P/N’s

3/8” x 3/4” long Hex Head Cap Screw

1

32253

3/8” Lockwasher

1

5197

3/8” Flat Washer

2

6593

BX Cable 3/8”

1

63292 (49”)

10460 (56”)

201465 (70”)

Straight Connector

1

16202

90° Connector

1

1417

Anti-short Bushing

2

16358

Black Wire 14 GA, 105°C

1

123150 (65”) 48862 (72”)

201466 (86”)

White Wire 14 GA, 105°C

1

123152 (65”) 48861 (72”)

201467 (86”)

Green Wire14 GA, 105°C

1

201468 (65”) 201462 (72”) 201469 (86”)

Cable Clamp, 1/2”

1

16227

#10 X 1/2” long Sheetmetal Screw

3

11813

Twist-on Wire Connector

10

16354

3.2 Preparing for

Installation

If the installation includes optional vertical louvers, downturn nozzle, polytube adapter,

duct flange, belt guard, blower guard, hanger kit, high altitude kit, multiple heater

control, sensor for DDC control, and/or stepdown transformer,

install these options

before the heater is suspended. Complete instructions are in this form or in the

option package; option packages are shipped separately.

Other shipped separate items could include a vent cap (Option CC1 for UDBP); a vent/

combustion air kit (Option CC2 or CC6 for UDBS); a manual gas valve; a thermostat

bracket kit; a thermostat; and/or a thermostat guard.

Be sure all options ordered are at the installation site.

Read this booklet and become familiar with the installation requirements of your par-

ticular heater. If you do not have knowledge of local requirements, check with the local

gas company or any other local agencies who might have requirements concerning

this installation. Before beginning, make preparations for necessary supplies, tools,

and manpower.

IMPORTANT: Shipping brackets are attached with cabinet screws. When remov-

ing shipping brackets, re-insert ALL screws into the cabinet.

To protect the unit during shipping, the heater has supports that must be removed

before installation. Follow these instructions to remove:

□

Blower Support Legs - Remove the two blower support legs and screws.

□

Motor Shipping Block (belt drive units) - Remove the wooden block located under

the motor bracket. Find the two rubber bushings shipped in the “Literature Bag”.

Place the bushings on the ends of the motor bracket bolts.

□

Motor Shipping Plate - Models equipped with belt drive motors of 3/4 HP or less

have a metal shipping plate attached between the motor and the blower housing.

Remove and discard the shipping plate.

NOTE: On units factory equipped with an

optional belt guard, the belt guard must be removed in order to reach the shipping

the plate.

Field-Installed Parts

If installing a Model UDBP or UDBS 150-400 ordered for use with 460 or 575 supply

voltage, a field-installed 500VA transformer is shipped separately. Be sure the trans-

former is there and follow the instructions in Paragraph 7.2 to attach it to the factory-

installed bracket.