0 electrical supply and wiring -27, 1 general, 2 supply wiring – Reznor UDBS Unit Installation Manual User Manual

Page 20: 4 blowers, belts, and drives (cont’d)

Form I-UDB, P/N 202658 R14, Page 20

7.1 General

All electrical wiring and connections, including electrical grounding MUST be made in

accordance with the National Electric Code ANSI/NFPA No. 70 (latest edition) or, in

Canada, with CSA Standard C22.1. In addition, the installer should be aware of any

local ordinances or gas company requirements that might apply.

7.0 Electrical

Supply and

Wiring

6.0 Mechanical

(cont’d)

6.4 Blowers, Belts,

and Drives

(cont’d)

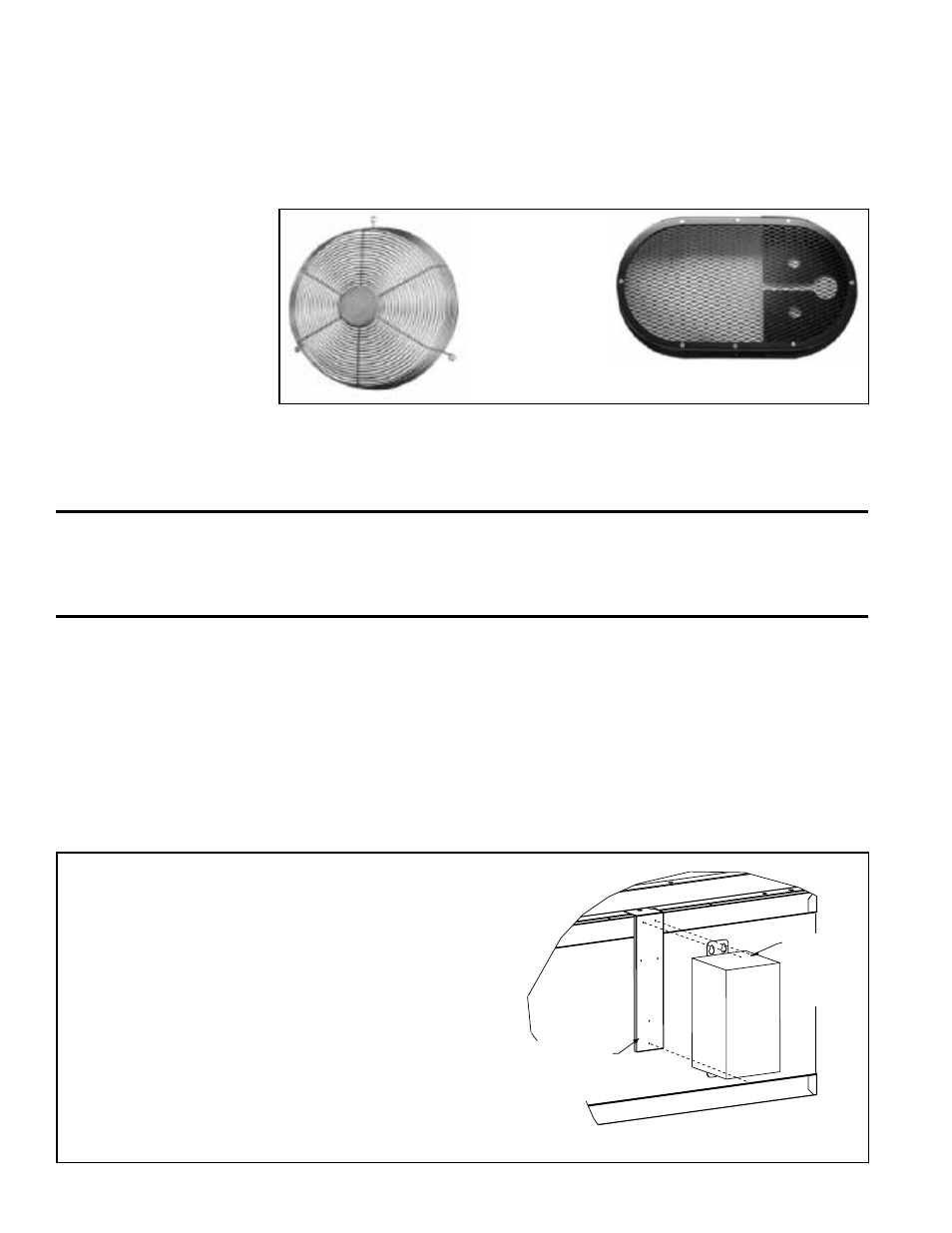

6.4.3 Blower and Belt Guards

Guard options are designed to provide complete protection from the rotating drive and

blower. Guards ordered as Option AZ6 or AZ7 are factory installed. Guards ordered as

Option CD10 or CD12 are shipped separately for field installation. The blower guard

only (Options AZ7 and CD12) is for Sizes 30-125 which have a direct drive motor. Both

guards are used on Sizes 150-400 which have a belt drive. The belt guard includes

a ground wire and screw. When the belt guard is field installed, be sure to attach the

ground wire and insert the screw into one of the holes in the blower housing.

Blower Guard

in Options

AZ6, AZ7,

CD10, and

CD12

Belt Guard in

Option AZ6 and CD10

FIGURE 14 - Optional

Belt and Blower Guards

are either factory or

field installed

(3) #10

Sheetmetal

Screws

(with the

transformer)

500V

A

Transformer

Transformer

Bracket

(factory

installed)

Side of

Heater

Opposite

the Control

Compartment

FIGURE 15 - Sizes 150-

400 with 460 or 575

supply voltage require

installation of a 500VA

Stepdown Transformer

Instructions for Installing the 500 VA Transformer

supplied with Size 150-400 units ordered for 460V or

575V supply (Components listed in Paragraph 3.2)

1. The transformer is shipped in its own carton. Remove the

transformer and the screws.

2. On the side of the heater opposite the access door, locate

the factory-installed bracket. Position the transformer on the

bracket and use the screws to attach the transformer.

3. Refer to the wiring diagram on the heater and the

connection information on the transformer. The transformer

has dual primary and secondary voltages, so be careful to

make the connections correctly.

Route the supply wiring in conduit from the transformer to

the entrance at the rear of the heater. Conduit retainers may

be attached to the edges of the heater cabinet or blower

back.

CAUTION: If any of the original wire as supplied with the appliance must be replaced,

it must be replaced with wiring material having a temperature rating of at least 105°C,

except for limit control, flame rollout, and sensor lead wires which must be 150°C.

See Hazard Levels, page 2.

7.2 Supply Wiring

Check the rating plate on the heater for the supply voltage and current requirements.

A dedicated line voltage supply with disconnect switch should be run directly from the

main electrical panel to the heater. All external wiring must be within approved conduit

and have a minimum temperature rise rating of 60°C

.

Conduit must be run so as not to

interfere with the heater access panel.

If an optional stepdown transformer, Option CG2 or CG4, was ordered, follow the

instructions shipped with the option package for attaching the transformer to the heater.

For wiring connections, refer to the transformer and the wiring diagram on the heater.

If the unit is a Size 150-400 with a 460 or 575 supply voltage, a stepdown transformer

is shipped separately and must be field installed on the unit. See the shipped-separate

list of parts in Paragraph 3.2 and follow the instructions in

FIGURE 15.