B&C Technologies DI-325 Industrial User Manual

Page 70

OPERATING AND PROGRAMMING INSTRUCTIONS

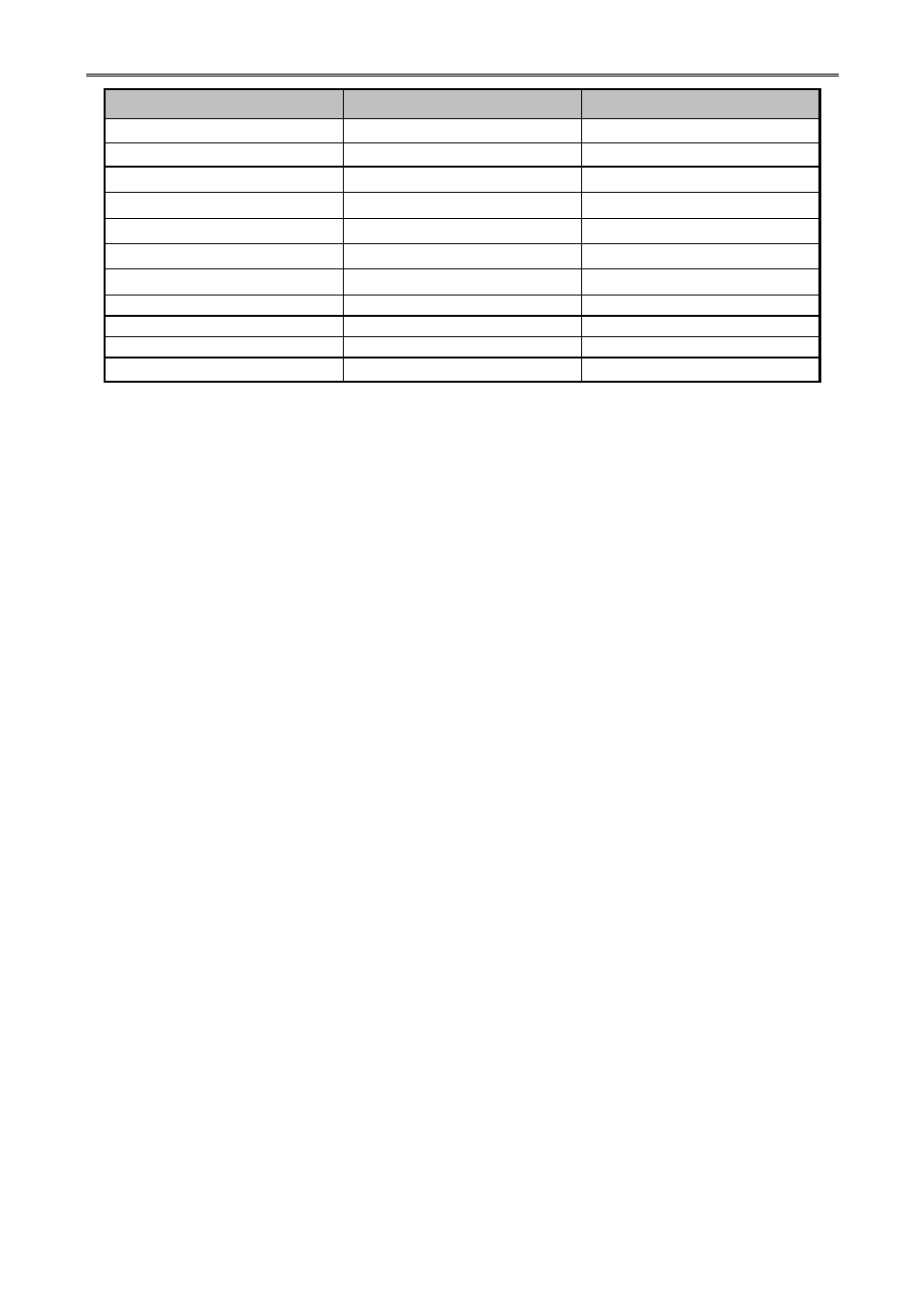

8-39

Program

Drying time

Drying temperature

1

40

167 °F / 75 °C

2

30

140 °F / 60 °C

3

30

113 °F / 45 °C

4

40

140 °F / 60 °C

5

25

122 °F / 50 °C

6

25

113 °F / 45 °C

7

25

104 °F / 40 °C

8

20

104 °F / 40 °C

9

0

n/a (only cool down)

10

50

194 °F / 90 °C

50

20

140 °F / 60 °C

8.2 Default machine parameter settings

The default machine parameter settings are:

01

Tmp

in

Fahrenheit

NO

05

Maintenance

cycl

0

06

Finished

beeptim.

5

s

07

Overview

status

0

11

RS485

stationnr.

1

12

RS485

baudrate 0

16

Cnt.reset no pass

YES

26

Rotation

time-out

10

s

27

Jog drum speed

25 %

30

Heater reset time

3 s

31

Blower clean time

5 s

32

Blower

WYE

del.

10

s

33

Del. check airflow

10 s

40

Max. inlet temp.

302 °F / 150 °C

9. Installing and setting up a controller

Installation of the basic controller kit is described in 9.1 below. The information given is

based on the controller only. It is important to review the documentation for the machine in which

the controller will be installed to ensure correct connection and use of the controller, and testing

procedures.

Optional kits are available to expand the capabilities of the controller. These are:

Infra-red sensor

(9.2) for more accurate measurement of garment temperature.

Humidity sensor

(9.3) for more accurate determination of linen dryness.

2

nd

NTC (temperature) sensor (9.4) for inlet temperature limiting and hence linen protection.

I/O expansion board (9.5) for providing additional input and output connections if required.

Please note that the infra-red and humidity sensors have an expansion board as part of the

kit. The DQ 01 controller has one connector for and expansion board so either the infra-red or the

humidity sensor can be fitted, not both. The 2

nd

temperature sensor can always be fitted.