B&C Technologies DI-325 Industrial User Manual

Page 13

INSTALLATION PROCEDURES

3-4

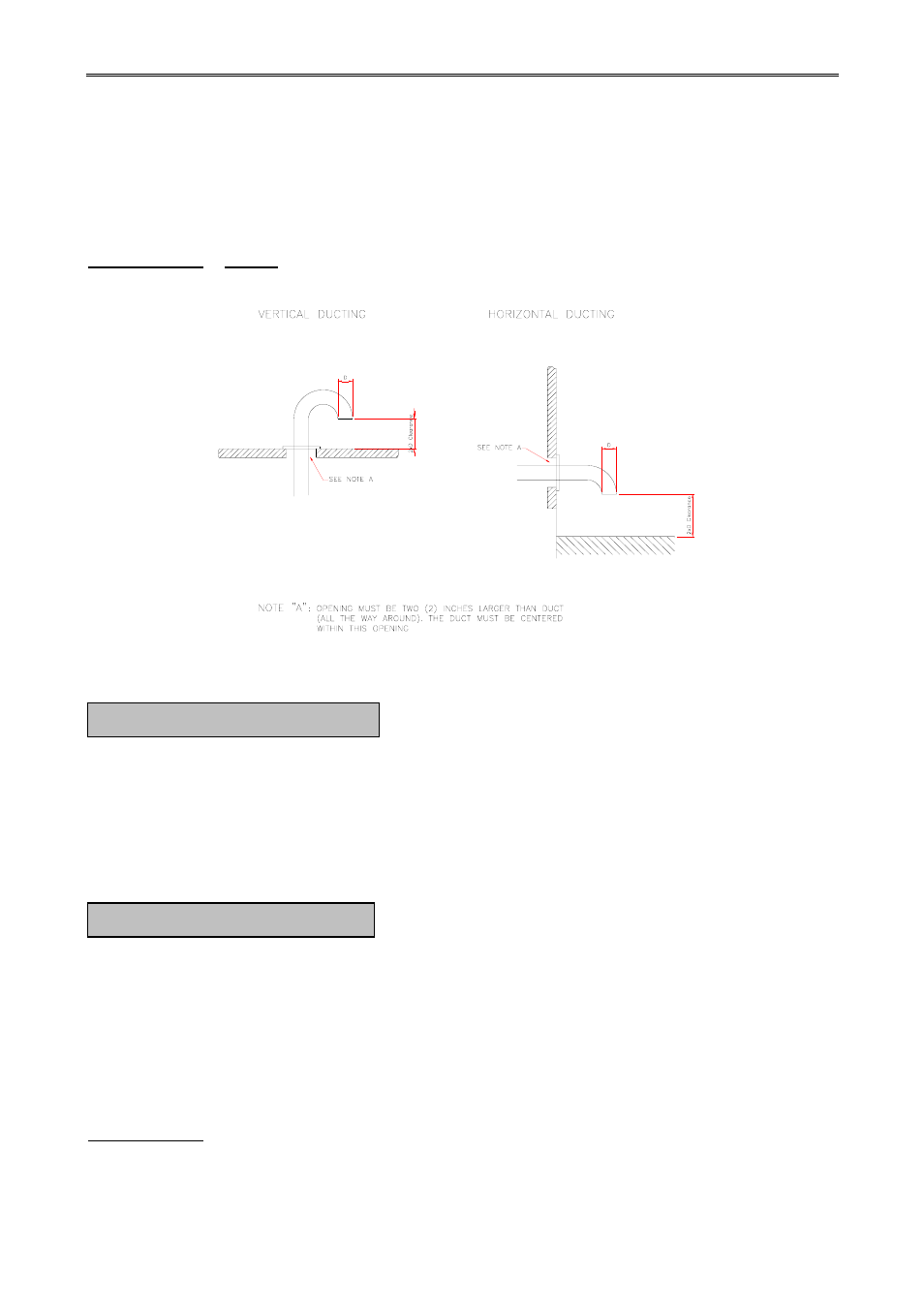

Outside Duct Work Protection

To protect the outside end of horizontal duct work from the weather, a 90

o

elbow bent

downward should be installed where the exhaust exits the building. If the duct work travels

vertically up through the roof, it should be protected from the weather by using an 180

o

turn to

point the opening downward. In either case, allow at least twice the diameter of the duct between

the duct opening and the nearest obstruction.

IMPORTANT: Do not use screens or caps on the outside of opening of exhaust duct work.

Figure.3-2 Outside Duct Work Connection

A clean, dry, regulated supply of 80 psi compressed air must be supplied to the dryer. The

connection size is 1/8 – inch N.P.T. No air filtering or pressures regulating devices are provided

with the dryer.

For gas model the air line supply connection is made into the 1/8 – inch N.P.T. port on the

air jet solenoid valve which located in the top of the dryer.

1.

Electrical Requirements

It is your responsibility to have all electrical connections made by a properly licensed and

competent electrician to assure that the electrical installation is adequate and conforms to local and

state regulations or codes. In the absence of such codes, all electrical connections, material, and

workmanship must conform to the applicable requirements of the National Electrical Code

ANSI/NFPA NO. 70 – LATEST EDITION.

IMPORTANT: Failure to comply with these codes or ordinances, and / or the requirements

stipulated in this manual con result in personal injury or component failure.

NOTE:

Component failures due to improper installation will VOID WARRANTY.

E. COMPRESSED AIR SUPPLY

F. ELECTRIC INFORMATION